Higher gear

Higher gear

Gear makers embrace indexable-insert tools.

All images courtesy Ingersoll Cutting Tools

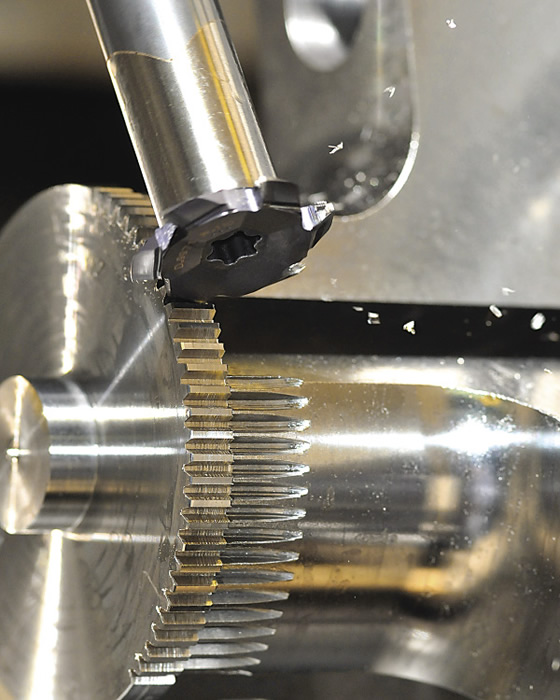

An operator at Allied Specialty Precision cutting a gear from 17-4 PH bar stock using an indexable tool.

By tradition, gear makers tend to be skeptical of new ideas. Most still generate gear teeth with single-point, HSS shapers, rack cutters or hobs, believing that indexable-insert tools cost too much, can't meet American Gear Manufacturers Association standards or are "not proven" enough.

More progressive gear makers tell a different story. By applying indexable-insert tools, many have gained substantial competitive and cost advantages. They are routinely tripling material-removal rates and tool life with no tradeoff in accuracy or surface finish. They have also gotten off the tool regrinding carousel, a bottleneck that often delays deliveries. Regrinding tools typically requires trafficking five expensive cutters through 5-week regrinding cycles just to keep a single process operating.

In many cases, these progressive thinkers have also dispensed with special-purpose hobbing machines and machine-to-machine part transfers. Some are even completing the entire gear—teeth, keyways and hubs—with "one-and-done" machining processes on general-purpose CNC machining centers.

Opening New Doors

The potential to improve gear machining stems largely from advances in indexable-insert carbide tools that enable them to repeatably hold much closer tolerances than previously possible. Indexable mills, including form tools, significantly perform better than and outlast HSS ones. They also routinely hold 0.0005 " (0.0127mm) repeatability to datum, axially and radially. That's more than good enough for the vast majority of gear machining applications. Moreover, many indexable tools or inserts can be replaced in the spindle, so chipmaking can resume in minutes with no touching off.

One case demonstrates many of these advantages. On an 8 AGMA 66.5 " shaft gear, a mining equipment manufacturer reduced tooth-generation cycle time from 34 hours to 8.5 hours by switching from HSS shaping to indexable-insert hobbing. The new process uses a 1.25DP Ingersoll single-start indexable hob on a Liebherr LC 2500 hobbing machine. The change also eliminated a separate rough sawing operation and mid-cut stoppages to replace tools. Cutting edges last for two complete parts and deliver an 80-rms surface finish to the roots of the shaft gear.

A modified standard Chip-Surfer slotting tool from Ingersoll forms teeth in two passes at Allied Specialty Precision, reducing cycle time by 20 minutes.

The process is essentially climb milling. Parameters for roughing are 110 mm/min. (4.33 ipm) surface speed, 0.90mm (0.035 ") axial feed per table revolution and a 42.45mm (1.67 ") DOC. For finishing, the respective parameters are 140 mm/min. (5.51 ipm), 0.300mm (0.012 ") and 5mm (0.197 "). The application reflects the trend toward using advanced indexable hobs for higher AGMA-class work.

The dramatic reduction in cycle time stems from two key differences between the hobbing and shaping tools. First, hobbing, a rotating-tool process with multiple cutting edges, keeps a cutting edge engaged in the cut much longer than a reciprocal-motion shaping process. Second, the indexable single-start hob allows higher speeds and feeds, leading to increased mrr and shorter cycle times.

One and Done

Another company, Allied Specialty Precision Inc., is milling gear teeth rather than hobbing or gashing them. As a result, the Mishawaka, Ind.-based company cuts gear teeth in half the previous time and completes all other operations in the same setup. "Now it's a pure one- and-done operation, even including the gear teeth," said Todd Stoddard, manufacturing engineer at Allied.

Cutting the teeth was always the longest part of these jobs, so, as order volume rose, Stoddard decided to streamline that operation. Andy Thornburg, field engineer for Ingersoll Cutting Tool Co., Rockford, Ill., suggested approaching the gear tooth forms as slots. Accordingly, the gear teeth are now milled with a form-matched Ingersoll replaceable-tip Chip-Surfer T-slotting tool rather than a HSS gear gasher. Cutting speed increased by a factor of 10 and tool life tripled.

The process change also reduced tooling cost per part from $20 to $2.56. Each Chip-Surfer replaceable tip costs about $125—approximately the same cost as one regrind of a $500 gear gasher. Fewer spares are needed as well, because the turnaround time for new tips is a few days, compared to up to 5 weeks for regrinding the gasher.

As the Worm Turns

Form milling also improves process economics for making the worms used in gear drives. Besides speeding up chipmaking compared to traditional hobbing, form-matched slotting mills running on 4-axis CNC machines also eliminate the need for limited-use hobbing machines and expensive hobbing tools.

Shops using this method report, on average, a 300 percent improvement in cycle time and tool life on a variety of worms compared to using form-matched worm hobs.

Ingersoll's modified standard Chip-Surfer carbide slotting tool.

"At some time in a worm machining process, the part is put on a mill anyway, at least to cut a keyway," said Ingersoll Tool Engineer Jeremy Bradley, who developed the worm-slotting method. "It's a matter of adding an operation to a milling process instead of transferring the part among machines and stocking six to eight spare tools to support the operation."

In one tooth-forming application, form milling with a modified standard Chip-Surfer completed a worm in a single pass, reducing cycle time from 14 to 4 minutes. Mounted on an alloy steel shank, the replaceable-tip cutting tool produced 60 to 80 pieces compared to 200 pieces between resharpenings for an HSS hob, but cost about one third as much as regrinding the $400 HSS hob, the average cost of which was $50. Traditional worm fabrication involves three separate operations, requiring two transfers among machines. First the bar stock is turned on one machine to generate the hub and worm ODs. Then the parts are moved to a mill to create nontooth-related features, such as flats and keyways. Finally, hobbing is performed on a dedicated machine.

A selection of typical worms for worm-gear drives.

In the new process, the form-matched slotter, running in a 4-axis program, generates the form as a milling operation, so the whole part can be completed on a single machine.

Other applications for replaceable-tip indexable tools include slotting and cavity milling and as replacements for comparable solid-carbide or HSS tools. Compared with a HSS tool, a replaceable-tip tool cuts faster and lasts longer. Compared with solid-carbide endmills, a replaceable-tip tool requires up to 90 percent less carbide. When mounted on an alloy-steel shank, it also eliminates the risk of tool failures due to vibration or excessive lateral forces. CTE