Tool warming

Tool warming

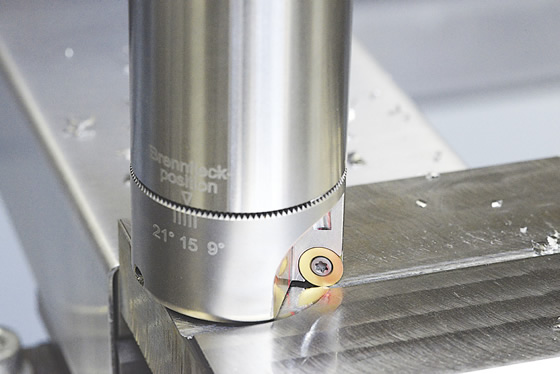

A through-spindle and through-tool laser-assisted milling process.

Heating difficult-to-machine workpieces before cutting them temporarily reduces material strength and, therefore, the machining forces required to process them. This, in turn, enables end users to extend tool life or, ideally, increase machining parameters to boost part throughput.

Having a laser beam travel in front of a cutting tool to warm the work is one established method for reducing required cutting forces. But the Fraunhofer Institute for Production Technology, together with several partners, developed the first laser-assisted milling system that directs the beam through the spindle and tool before it exits the side of the tool to heat the material being cut, said Jan-Patrick Hermani, an engineer for the institute.

The Fraunhofer Institute for Production Technology, together with several partners, developed a laser-assisted milling system that directs the beam through the spindle and tool before it exits the side of the tool to heat the material before it is cut.

He noted the project, which won the MM Award at last year's EMO trade show for metalworking and metal- forming machine tools, included development of the machine tool spindle, laser controller and cutting tool. Toolmaker Rineck Maschinenbau GmbH provided the endmill, which is tooled with TiAlN-coated carbide inserts.

The institute conducted machining tests with various workpiece materials and found that the titanium alloy Ti4Al6V begins softening at about 500° C (932° F) and reduces cutting forces by 50 percent, Inconel 718 softens at 900° C (1,652° F) and reduces forces 50 to 60 percent, and silicon-nitride ceramic softens at 1,200° C (2,192° F) and reduces process forces by 90 percent.

However, a material shouldn't be heated to its melting point because the material will weld onto the inserts and damage them, Hermani noted. In addition, the required softening must be as deep as the tool's feed per tooth.

Although titanium and nickel-based superalloys can be conventionally milled, that's not the case with silicon nitride, according to Hermani. "Silicon nitride ceramic is very brittle, so you cannot mill it without heating it before machining."

The system only requires a 3kW power source, Hermani pointed out.

The institute programmed the laser, which rotates with the tool, to switch the laser on and off during machining so that it is on as the insert enters the cut and off as the insert exits the cuts. The programming also adjusts the laser power according to chip thickness, cutting velocity and feed rate, with more power needed as each parameter increases. "At the beginning of the cutting insert engagement, we might have the biggest chip volume, so we need high laser power," he said. "At the end, we might have a small chip volume, so we reduce the laser power to zero."

Because of the demanding programming requirements for the laser parameters, the institute has only used the laser-assisted milling system to produce simple parts, according to Hermani, adding that "for 5-axis milling, it is difficult."

For more information about Fraunhofer Institute for Production Technology, Aachen, Germany, visit www.ipt.fraunhofer.de or call +49 241-8904-0. For more information about Rineck Maschinenbau GmbH, Marienfeld, Germany, visit www.rineck.de or call +49 5247-9865-0.