Crystal persuasion

Crystal persuasion

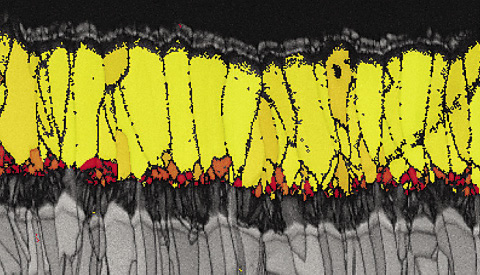

A CVD tool coating with unidirectional crystal orientation.

A random arrangement is all well and good when it comes to avant-garde music, but the random crystal growth direction found in conventional CVD alumina cutting tool coatings can create weak areas where cracks form, shortening tool life. According to Sandvik Coromant Co., the new Inveio CVD alumina coating on its GC4325-grade inserts has a unidirectional crystal orientation—where every crystal is aligned in the same direction—that resolves that issue.

A CTEplus video supplement

"The crystal structure is oriented where the strongest direction of the crystal is pointing toward the cutting edge," said John Winter, product and application specialist for the toolmaker. "With that tightly packed crystal structure, you eliminate weak spots within the coating, which allows the performance of the cutting edge to be more consistent."

He added that the coating structure also helps disperse heat along the crystal planes and away from the cutting zone. Based on the company's tests, the new coating increases tool life 20 to 30 percent. In addition, because end users have a high level of tool life predictability with the inserts, they are appropriate for unattended machining.

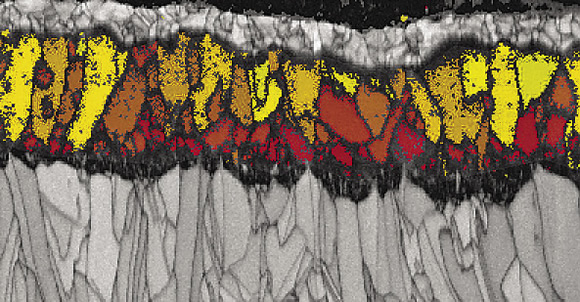

Courtesy of Sandvik Coromant

Compared to a conventional CVD alumina coating (bottom), in which each crystal direction is represented by a different color, the crystals in Sandvik Coromant's Inveio coating are oriented in the same direction as shown by the uniform yellow color.

Prior to depositing the coating, the toolmaker brushes the cutting edge line of an insert to achieve a consistently tight tolerance from batch to batch, Winter explained. After deposition, the insert is media-blasted to remove the top gold-colored TiN coating layer, exposing the black alumina, or aluminum oxide, layer underneath. This smooths the coating to minimize the risk of workpiece material adhering to the top layer. However, the TiN coating remains on the edge where flank wear occurs, providing a wear-detection mechanism for the operator because it's easy to see the black coating once the gold layer wears.

GC4235-grade inserts are targeted toward P-25 steel applications. "You have low-carbon steel, high-alloy steel and anything in between," Winter said, adding that the inserts have also successfully cut stainless steel and cast iron. "Every aspect of the insert has been designed and developed to create a more wear-consistent insert in the P-25 arena."

For more information about Sandvik Coromant Co., Fair Lawn, N.J., call (800) SANDVIK or visit www.sandvik.coromant.co/us.