Replace an outdated vertical machining center with a new one

Replace an outdated vertical machining center with a new one

Boost productivity when machining hubs and other parts. Replace an outdated vertical machining center with a new one.

END USER: Stock Drive Products/Sterling Instrument, (800) 819-8900, www.sdp-si.com.

CHALLENGE: Boost productivity when machining hubs and other parts.

SOLUTION: Replace an outdated vertical machining center with a new one.

SOLUTION PROVIDER: DMG/Mori Seiki USA Inc., (847) 593-5400, www.dmgmoriseikiusa.com.

An old machine tool may still function properly, but that doesn't necessarily mean it's an asset to a contract manufacturer or job shop. Stock Drive Products/Sterling Instrument typically replaces its machines after about 5 years of use to keep pace with machine technology and take advantage of ongoing improvements, according to Robert Zeisler, manager of the application engineering group for the New Hyde Park, N.Y., company.

SDP/SI offers more than 130,000 line items, including pulleys, timing belts, gears, shafts, bearings, U-joints, couplings and right-angle drives. Zeisler noted 80 to 85 percent of them are primarily manufactured at the company's two machine shops. The company also machines parts for domestic and foreign customers. SDP mostly produces parts for commercial and medical applications, while SI generally targets the aerospace and military fields.

Courtesy of SDP/SI

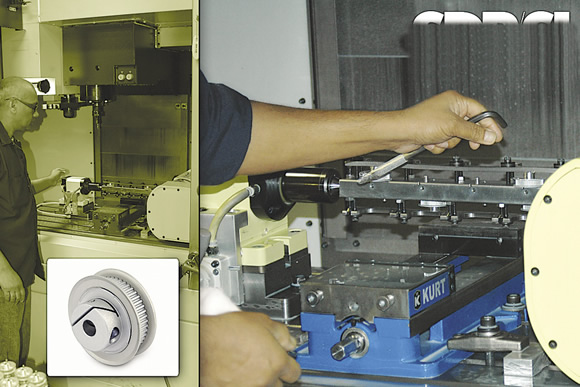

Dharmdeo Sookhai, foreman for SDP/SI's CNC milling department, with the company's DuraVertical 5100 5-axis VMC from DMG / Mori Seiki USA.

Courtesy of SDP/SI

SDP/SI machines the Fairloc hub on its DuraVertical 5100 VMC.

Some of SDP's machine tools are from a builder that's no longer in existence. After examining various offerings to replace an outdated 4-axis vertical machining center while adding another machine, SDP/SI selected a DuraVertical 5100 5-axis VMC and DuraVertical 1035 ECO 4-axis VMC from DMG/Mori Seiki USA Inc., Hoffman Estates, Ill., noted Dharmdeo Sookhai, foreman for SDP/SI's CNC milling department. Not only was the parts manufacturer familiar with the machine tool builder's products and their capabilities, SDP/SI previously purchased a DuraVertical 5100. "It's a very high-precision and fast machine tool," he said. "The productivity from it is outstanding."

In addition to the standard X, Y and Z axes, the DuraVertical 5100 has a rotating 4th axis that can turn angularly about a 5th axis. All five axes can move simultaneously to perform intricate machining operations and create whatever geometry is necessary. That's beneficial when producing "high-tech" components, such as ones with complex contours for the medical and military industries, Zeisler pointed out.

Another suitable part for that machine is SDP/SI's Fairloc hub, which requires a countersink, drilled clearance hole, tapped hole and two angular cuts. The DuraVertical 5100 produces the part in one setup. The company machines eight hubs per fixture, and Sookhai noted that VMC machines a fixture of parts in 7 minutes compared to 9 minutes on the previous machine. "We do these parts by the thousands [annually]," he said.

"The demand is getting so huge that we had to get a quicker, newer and more precise machine to make the part," Zeisler added. "We're proud we can turn these parts around quickly."

With an X-axis travel of 41.5 " (1,050mm), Y-axis travel of 20.9 " (530mm) and Z-axis travel of 20.1 " (510mm) for the DuraVertical 5100, SDP/SI can quote larger parts. Previously, the company was limited because of the previous machine's capacity and travel capabilities, Sookhai pointed out.

The number of different parts the 5-axis milling machine can create is vast, thanks in part to SDP/SI's inventory of more than 500 custom fixtures that it produced in-house, Zeisler explained. Not only do the fixtures support large quantities in a single run, a new fixture is not required if a similar part needs to be machined. This is because the fixture already in place can be adjusted to make the required changes to hold the part.

"We just have to do minor changes on a fixture, like changing the pin for a different bore and adjusting the jackscrew up or down," Sookhai said.

This further increases the output of any SDP/SI machine by decreasing setup time.