Multitask machining heroes

Multitask machining heroes

Produce parts faster without investing in additional fixturing. Efficiently reprogram the parts with the company's CAM software after moving part production to a multitask lathe.

END USER: Holmatro Inc., (410) 768-9662, holmatro-usa.com.

CHALLENGE: Produce parts faster without investing in additional fixturing.

SOLUTION: Efficiently reprogram the parts with the company's CAM software after moving part production to a multitask lathe.

SOLUTION PROVIDER: DP Technology Corp., (800) 627-8479, www.dptechnology.com.

The hero isn't always the guy in the cape. Symbols of the modern white knight notwithstanding, sometimes he doesn't even wear a badge or ride on a fire engine.

In this case study, the guys in the "white hats" are with Holmatro Inc., a manufacturer of rescue equipment—including hydraulic spreaders, cutters and rams—used to extricate people pinned inside vehicles after traffic accidents.

"Getting rid of the metal when someone is trapped is the first thing rescuers do when they assess the accident scene," said Chuck Cain, manufacturing engineer at Holmatro's Glen Burnie, Md., facility. "Anything we can do to chop minutes off at the scene can make a real difference."

He added that the company continually invests in R&D to find ways to make better products. "Innovation is fun for me, and it all comes down to having the right tools for the job," Cain said.

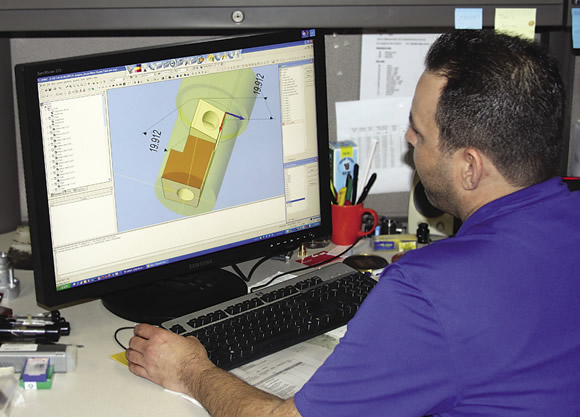

One of those tools is CAM software. When shopping for a CAM package in the past to eliminate the programming of machine tools longhand at the control, Cain noted Holmatro examined the offerings from "everybody in the CAM business" before selecting ESPRIT CAM software from DP Technology Corp., Camarillo, Calif.

Cain explained that one of the reasons for choosing ESPRIT is it helps impart specified finishes of 0.3µm Ra to 1.6µm Ra by properly adjusting the speeds and feeds during machining based on cutting conditions. This is especially critical when producing parts with contoured surfaces. "ESPRIT keeps everything consistent," he said.

Smooth bore surfaces are essential for hydraulic components. This is because the company's pumps flow hydraulic fluid at 10,500 psi, and the high-pressure flow increases the effects of any imperfection by making it bigger, such as a line, on a bore for a hydraulic cylinder, Cain pointed out. "It gets real ugly quickly, because any surface imperfections create a path for hydraulic oil to flow between the cylinder wall and the O-ring," he said. "At 10,500 psi, that path would cause the O-ring to fail."

More recently, Cain noted the CAM software provided a solution when the vice president tasked him with boosting throughput for runs of 300 pump coupling adapters. Holmatro produced the part unattended on a horizontal machining center, but was only able to make 32 pieces a day. To increase production of the parts and utilize a full 24-hour day instead of just the cycle time from running one set of fixtures, Holmatro would have had to purchase five vices and five riser plates for a total cost of at least $36,000. "That job was truly a bottleneck," Cain said.

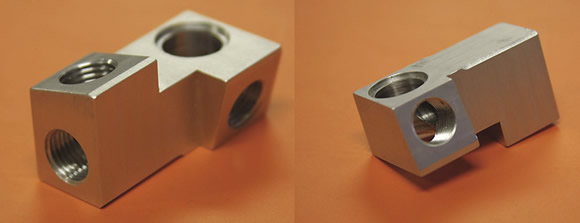

Manufacturing Engineer Chuck Cain uses ESPRIT CAM software to program parts, such as an adapter to connect the pressure and return oil flow from the pump to the desired rescue tool (bottom image), for Holmatro's products.

The company elected instead to move the part to a lathe with a milling spindle, so Cain reprogrammed the part. ESPRIT made this easy because it can generate the complex code that's required when integrating milling and turning operations, Cain said. "In this case, we also utilized a 4th axis to do the A-axis index machining."

By eliminating the investment in an A-axis indexer, the company also avoided additional part handling. "Every time you touch a part in a machine shop, you stand a chance of losing accuracy," Cain said.

Moving the part to the lathe enabled the shop to use round instead of square bar stock, Cain added. This eliminated having a worker saw 300 slugs about 68mm long for each run. "He was there a long time handling that job," he said. "Now, we cut the stock into 4 '-long round bars and just put them in the bar feeder."

Holmatro had to buy a soft collet, purchased for $300 from MicroCentric, for the second operation, milling, because the bar was not round after turning.

With this improved approach, Holmatro produces 32 pump coupling adapters during the day and 95 at night unattended, enabling a 3-minute reduction in cycle time and an overall 296 percent increase in production. Cain estimates Holmatro runs the job at least once a month and saves about $5,200 annually as a result of the change.

When the ultimate task at hand is saving lives, efficiency has a whole new meaning. "We always want to make sure we provide w