More tips for a manual mill

More tips for a manual mill

Shop Operations columnist Tom Lipton offers tips for enhancing the operation of a manual milling machine.

Continuing the theme of December's column, this month's column provides more tips for enhancing the operation of a manual milling machine.

• Sometimes it's faster and easier to make a quick drill fixture to drill and tap holes in the edges of large plates. Otherwise, the setup time and handling can be murderous for just a few holes. Make the block an accurate size so you can locate it precisely on the plate.

• A "poor man's" knee rapid feed saves you quite a bit of time over the course of a year (see photo, right). It has wrench flats on the shank so you can still make fine adjustments with a wrench. Nobody can say I'm not a cheapskate.

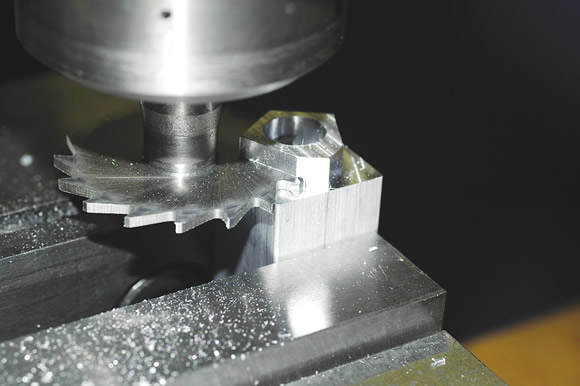

• Once a part is completed, cut it off with a slitting saw or keyseat cutter. This works particularly well for small parts (see photo, opposite page). Be sure to keep your eye on the part when it comes off or you might spend more time looking for the part than it took to make it.

• Use a right-angle head like a precision cold saw to neatly and accurately cut parts to length. This is an effective use of a retractable stop to eliminate parts jamming between the stop and the blade. Use blades with enough thickness to cut straight. You should be able to cut parts within 0.002 ". Make sure the bottom of the right-angle head clears the parts and the vise. Also, be sure to retract your stop before the part comes off or it may jam.

• You can quickly align the right-angle head if the vise is positioned correctly. With the clamp screws for the head lightly clamping the body, drop the head into the jaws of the vise and snug the vise slightly. For fussy work, you will still want to indicate the head for perfect alignment. By the way, don't trust the flats on the side for fussy work. Indicate a test bar held in a collet.

Courtesy of All images: T. Lipton

A "poor man's" knee rapid feed saves you quite a bit of time over the course of a year.

Once a part is completed, cut it off with a slitting saw or keyseat cutter. This works particularly well for small parts.

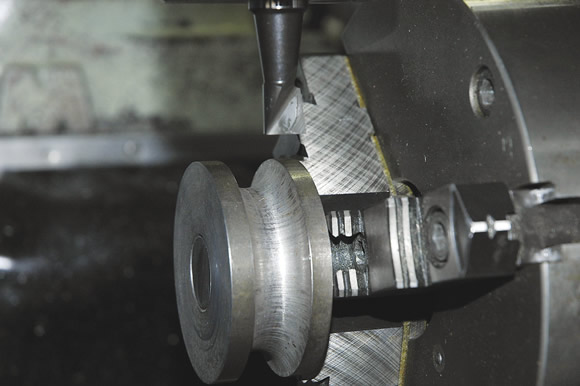

Cut odd radii, such as a tube-bending die for an odd centerline radius, with a boring head.

• Cut odd radii, such as a tube-bending die for an odd centerline radius, with a boring head. Such a part can be rotated by the rotary table with the boring tool's cutting edge on the centerline.

• Cut chamfers with a standard countersink. Stay off the tip for best results.

• Place a piece of brown paper under plates clamped to the mill table. This bit of paper acts like a brake lining to keep a part from slipping.

• Try using annular cutters when holemaking. They produce accurate holes and need a fraction of the feed pressure to effectively cut compared to drill bits. You also create a neat little slug, which you can use to make something else. In addition, annular cutters are more efficient than drill bits. The cutting speed of a standard drill bit approaches zero at the tip. Essentially, the center portion of a drill bit is broaching its way through the material. Annular cutters maintain a more uniform cutting speed and convert more energy into the hole and less energy into chips. However, you should not stack-cut with annular cutters.

• Annular cutters could care less if they cut a full hole or some fractional part of one. The helical flutes on the outside of the cutters extract the chips, unlike a hole saw.

After two pecks, clean the teeth of a hole saw with a small wire brush or air hose while it's running.

• When applying hole saws in a mill, only stay in the cut for about 3 seconds at a time, backing the saw out after each 3-second peck. After two pecks, clean the teeth of the hole saw with a small wire brush or air hose while it's running. This clears the chips out of the teeth and keeps the tool cutting. Also, predrill one to four holes in the saw groove to break the chips and strip them out of the teeth.

• Mill your blocks square with the end cutting surface of the tool. Less tool flex improves part quality.

• Check flatness of parts with a three-point leveling system. Level the underside datum to the same indicator reading. Then sweep the top surface of the part, flip and repeat.

• Use a V-block for holding round stuff in a mill vise. It provides three-point contact and automatically and accurately squares the stock to the jaw. An extra tall V-block can be set up with a couple of angle plates. One advantage of doing this is it allows setting up any desired angle between the two plates. Be sure to indicate the faces vertically to ensure they are straight. You can also leave a space between the plates for clamping purposes.

• You also can make a soft jaw that has a V-groove already in it when three-point holding various round items. CTE

About the Author: Tom Lipton is a career metalworker who has worked at various job shops that produce parts for the consumer product development, laboratory equipment, medical services and custom machinery design industries. He has received six U.S. patents and lives in Alamo, Calif. Lipton's column is adapted from information in his book "Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators," published by Industrial Press Inc., New York. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2013 when ordering, CTE readers will receive a 20 percent discount off the book's list price of $44.95.

About the Author: Tom Lipton is a career metalworker who has worked at various job shops that produce parts for the consumer product development, laboratory equipment, medical services and custom machinery design industries. He has received six U.S. patents and lives in Alamo, Calif. Lipton's column is adapted from information in his book "Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators," published by Industrial Press Inc., New York. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2013 when ordering, CTE readers will receive a 20 percent discount off the book's list price of $44.95.