Inovatools’ tooling eases aluminum machining

Inovatools’ tooling eases aluminum machining

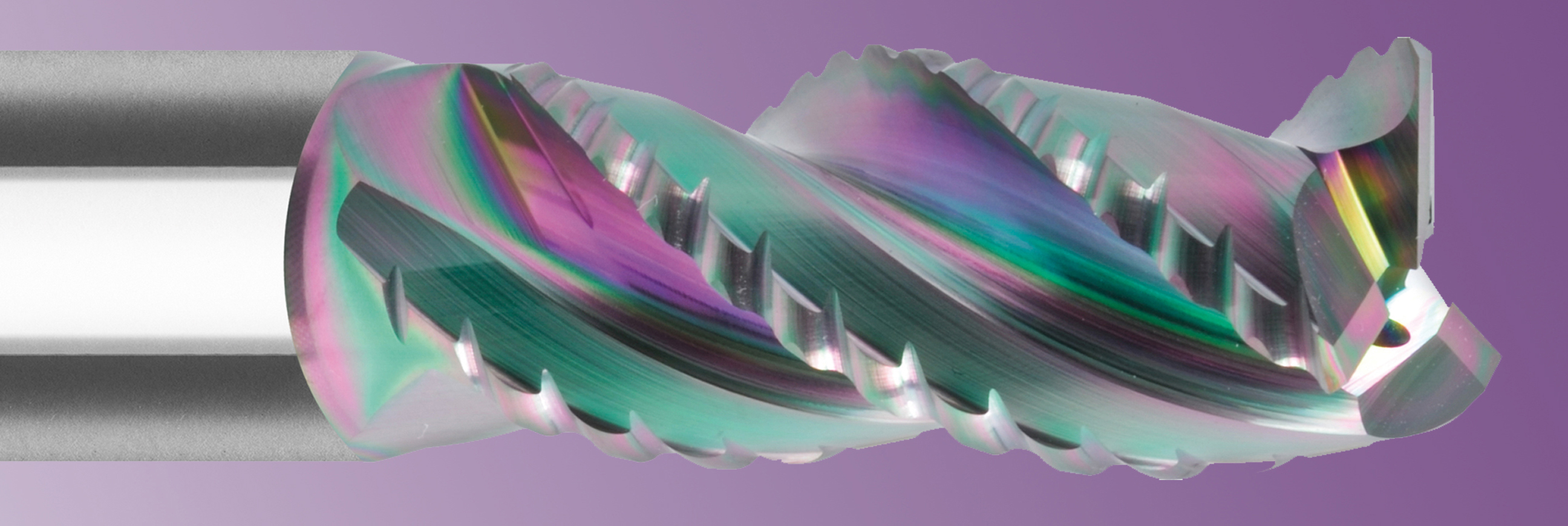

A new line of aluminum tools from Inovatools utilizes the ta-C thin-layered coating that the company says makes the process of machining aluminum and its alloys more productive and cost-effective.

A new line of aluminum tools from Inovatools utilizes the ta-C thin-layered coating that the company says makes the process of machining aluminum and its alloys more productive and cost-effective.

A new line of aluminum tools from Inovatools utilizes the ta-C thin-layered coating that the company says makes the process of machining aluminum and its alloys more productive and cost-effective.

Inovatools USA LLC, a Germany-based company with U.S. offices in Hartland, Michigan, released its VHM line of aluminum tools that feature an amorphous, hydrogen-rich ta-C carbon high-performance thin-layered coating that has a microhardness of 6,000 to 7,500 HV. It is a wear-resistant variant of diamond-like carbon (DLC) coatings that allows for efficient machining of challenging materials such as aluminum with a maximum silicon content of 10%, copper materials, graphite, glass-fiber-reinforced plastic (GFRP) and carbon-fiber-reinforced plastic (CFRP).

The coating has excellent sliding properties, and its coating hardness amounts to roughly 60% to 80% of the hardness of a diamond coating, the company says.

It is wear-resistant and low-friction in both lubricated and unlubricated applications. The coating is applied at less than 250°, which means that even temperature-resistant substrates can be coated without the geometry changing. It can be applied thinly enough to prevent the rounding of sharp cutting edges.

In a comparative test involving machining an aluminum section made from AlMg0, 7Si (diameter: 16 mm, Z = 3, type W, helix angle = 20°, polished chip groove, service life criterion = burr formation), and a ZrN-coated mill (2,000 HV) managed 2,000 acceptable parts. A mill from the Inovatools ta-C tool range (6,000 to 7,00 HV) achieved 10,000 acceptable parts.

Tools for every application

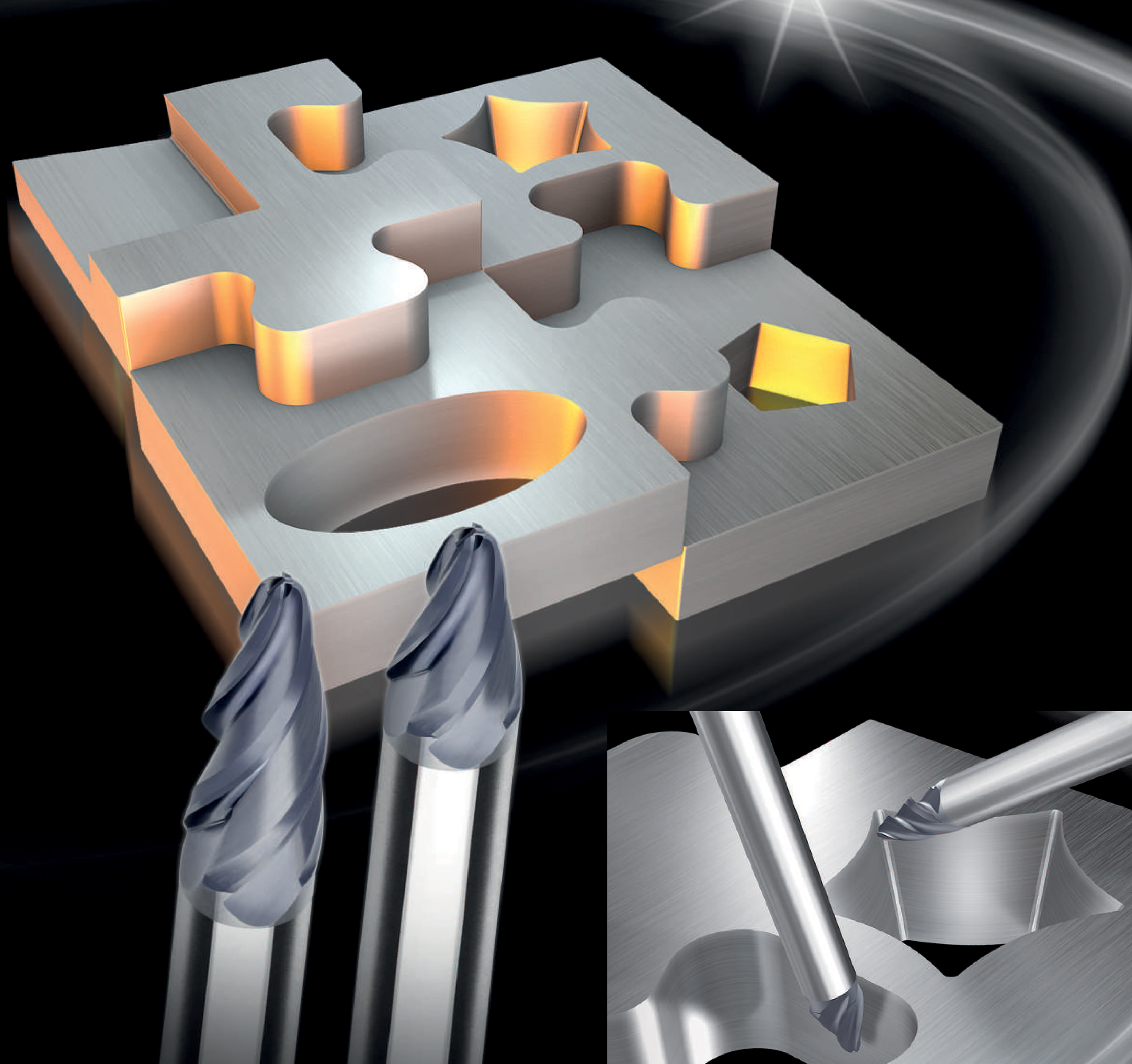

The mills from the new Inovatools ta-C range for aluminum machining are ideally matched to their applications and milling strategies in terms of substrate, geometry and coating. The line-up includes single- and multi-edged tools for roughing and finishing, long and short versions, variations with corner radius and full radius, for standard use and for HPC, HSC and trochoidal (TSC) applications.

One exa mple from the ta-C series is the Primus HPC aluminum roughing end mill. With internal cooling and multi-turning, the Primus is equipped to deliver consistently quiet, low-vibration, energy-efficient performance at extremely high-feed rates. The tool has a special knurled section with optimized chip control as well as the ta-C coating that enables it to eliminate the usual problems in cutting aluminum such as high adhesion tendency with built-up edges, welding deposits, chip caking, and burr formation.

mple from the ta-C series is the Primus HPC aluminum roughing end mill. With internal cooling and multi-turning, the Primus is equipped to deliver consistently quiet, low-vibration, energy-efficient performance at extremely high-feed rates. The tool has a special knurled section with optimized chip control as well as the ta-C coating that enables it to eliminate the usual problems in cutting aluminum such as high adhesion tendency with built-up edges, welding deposits, chip caking, and burr formation.

The coating, combined with its microgeometry in conjunction with the cutting-edge preparation, make the tool highly resilient. This prevents micro-chipping and makes the cutting edges more resilient. This "defect-free cutting-edge design" considerably increases the service life of the Primus. This is supported by the entwined profile's special chip separators. They break the aluminum chips quickly and at an early stage, and, thanks to large chip grooves, can be rapidly transported away from the engagement zone with cutting fluid. Not only does this bring a high level of process security, it also ensures low-vibration running for high-surface quality, even during HPC roughing. This means that Primus tools operate with minimal vibrations even at exceptionally high feed rates; for example, during the machining of aluminum for airplanes.

The three-edged Primus is available in diameter ranges from 6.00 mm to 20.00 mm, with internal cooling, multi-turning and straight and Weldon shank designs.

During a customer test in cutting aluminum 3.2315 (AlMgSi1/AlSiMgMn), the Primus proved up to 30% more cutting capacity than previous tooling options. With cutting data of D1 = 20 mm, ae/ap = 1xD, vc = 750 m/min, fz = 0.3 mm, the Primus achieved a cutting volume of 4,297 cm3/min compared with the 3,008 cm3/min of the reference tool.

In addition to the ta-C series, the company recommends other mills and drills including the CurveMax CSC (curve segment cutter) with a ta-C coating for aluminum structural components or copying applications, such as in the aerospace industry. The CurveMax mills' special geometries permit bigger path distances and line jumps during pre-finishing and finishing. Although the working radius is larger than that of a traditional full-radius mill, the tool still has the same diameter.

In addition to the ta-C series, the company recommends other mills and drills including the CurveMax CSC (curve segment cutter) with a ta-C coating for aluminum structural components or copying applications, such as in the aerospace industry. The CurveMax mills' special geometries permit bigger path distances and line jumps during pre-finishing and finishing. Although the working radius is larger than that of a traditional full-radius mill, the tool still has the same diameter.

"Extreme feed rates, more cutting volume – tools from Inovatools for machining aluminum and its alloys show that it is possible to employ optimizations to aspects of design such as microgeometry, chip control, grinding and high-performance coatings to take aluminum machining to a whole new level of performance," said Nilüfer Cebic, head of product management and marketing at Inovatools.