Economical solution introduced for flexible ‘V’ block fixturing

Economical solution introduced for flexible ‘V’ block fixturing

Finally, a unique take on the traditional V-Block which allows you to complete a wider range of projects than ever before. Introducing the Uni-Vee, a useful solution to some common and tedious workpiece fixturing difficulties.

Article from Uni-Vee

Finally, a unique take on the traditional V-block which allows you to complete a wider range of projects than ever before. Introducing the Uni-Vee, a useful solution to some common and tedious workpiece fixturing difficulties.

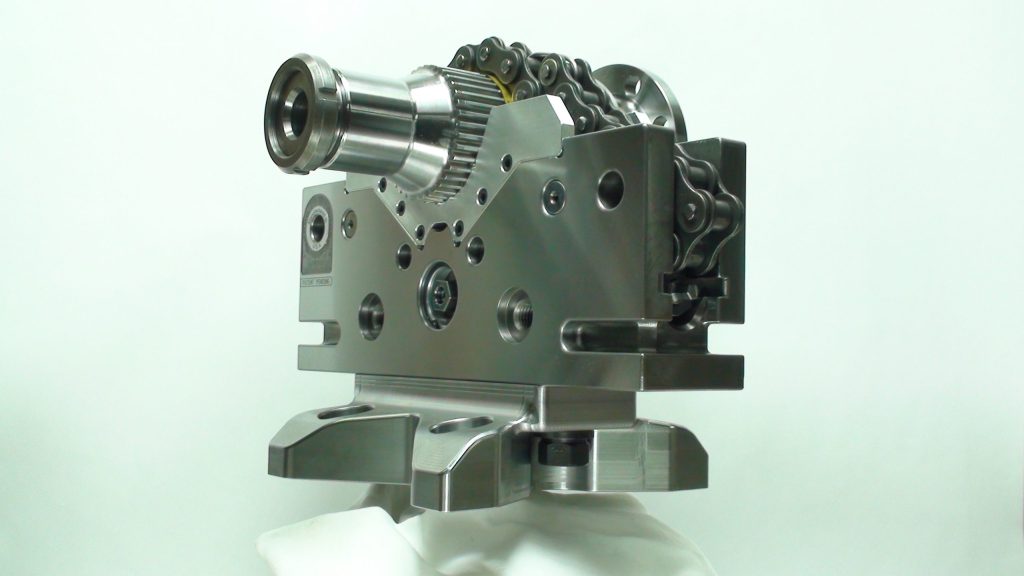

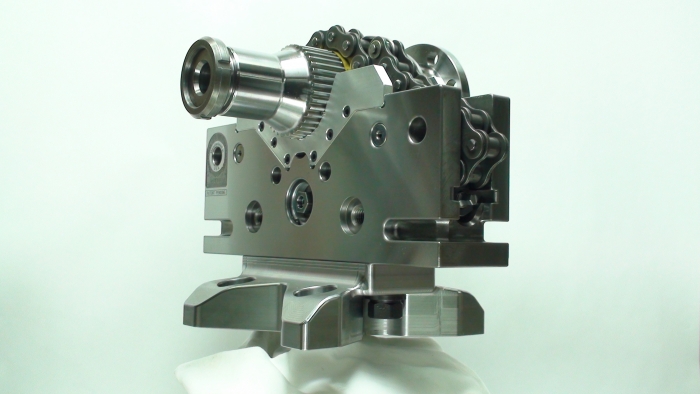

What sets the Uni-Vee apart from traditional fixtures? The Uni-Vee's unique design makes it the most economical solution for flexible V-block fixturing. The Uni-Vee is configured with a geometrically correct rectangular main body indexable in 90-degree rotational increments about its centerline to allow quick, repeatable positioning.

Specifically, it allows the ability to quickly and accurately rotate the fixture 180 degrees, allowing a number of benefits for machine work.

An aircraft propeller shaft is mounted in Uni-Vee. The jaws (front and back) were custom shaped for this part. Uni-Vee is installed on the optional indexing base plate. This allows removal of the part from the machine bed and re-installation on the machine bed (or another machine bed) without re-location prior to continuing the machining process.

With no protrusions on its front, back or bottom, Uni-Vee can be installed directly into the shop milling vise or to lay flat on a table or surface plate. This also facilitates laying down the Uni-Vee for the contouring of custom jaws, eliminating the need for a special fixture and a chance to increase the accuracy of shop-built jaws.

With the Uni-Vee, end users can:

Take on unique jobs. Complete jobs your shop would never have taken before, now with confidence and ease. The Uni-Vee's versatility makes otherwise difficult setups easy and quick.

Only worry about setting up once. Move the workpiece on and off your machine bed or to QC without having to set up again. The workpiece remains solidly engaged within the Uni-Vee.

The Uni-Vee holds a prototype V12 crankshaft design for an aircraft.

Uni-Vee's indexing feature and clamping security offers both a faster set up, and plenty of holding power for efficient cuts with precision.

It was created by a machinist, for machinists. Uni-Vee's creator is a long-time West Seattle, Washington, resident. Mark Dunlap is a tool and die maker who learned his profession the old school way – he started in the shop with a broom and a clean floor as his chief responsibility. 30 years later, Dunlap owns his own shop and is known well in the Seattle area. The customers who seek the expertise of Dunlap are looking for someone who can deliver on the

challenge of impossibly complicated parts, ridiculous turnaround times, clearances, finishes and

tolerances. In short, jobs no one else will take on.

It is not unusual to see a part in process that could be an axle for a NASA telescope, a splined shaft for an undersea vessel moored in Bangor, Washington, or a die that engineers at the local airliner manufacturer just don't know how to fix so they seek Dunlap's advice. Not uncommon either is a corporate jet from Alaska waiting at Boeing Field to load a part recreated for a fish processing machine. When the machine breaks down, fishermen quit fishing until Dunlap delivers the new part.

A new V block was born of a need to hold 8″-dia. round stock of 4340 for the purpose of machining a prototype crankshaft for a V12 aircraft engine. The V-block Dunlap fabricated functioned so well that the idea was refined and brought to market as the Uni-Vee.

The Uni-Vee in an EDM.