3D Printing: Hybrid machines put ‘done in one’ on the table

3D Printing: Hybrid machines put ‘done in one’ on the table

Are hybrid machine tools the next big step in the evolution of manufacturing?n

Additive manufacturing — particularly metal additive manufacturing — is having a profound effect on the way companies make things. U.S. aerospace manufacturer Pratt & Whitney, for example, 3D-prints production quantities of the compressor stators and sync ring brackets for its PurePower Geared Turbofan engine. Medical manufacturer Mantiz Logitech Co. Ltd. of South Korea uses additive manufacturing to produce titanium spinal implants. U.K.-based HiETA Technologies Ltd. specializes in metal 3D-printed modular heat exchangers. That's just a small sampling.

There's only one problem with these and countless other 3D-printing applications: The metal parts coming off these machines often require extensive post-processing. At the very least, this means slicing parts off the "build" plate, heat treating to remove internal stresses, then bead blasting or vibratory finishing.

Various features demand machining as well in most instances. Threaded holes must be reamed and tapped. Cosmetic surfaces necessitate a cleanup pass. Critical dimensions need milling, turning or grinding. All this drives up costs and extends lead times.

In this era of multitask machine tools, wouldn't it be wonderful to eliminate some or all of these secondary operations and produce finished parts in a single operation rather than many?

By networking separate additive and subtractive machines together, GF Machining Solutions and 3D Systems have developed the DMP Factory 500 and DMP Factory 350 modular hybrid manufacturing cells. Image courtesy of GF Machining Solutions

Greater Than the Sum of Its Parts

Paul Kingsley, senior applications engineer for additive manufacturing at Okuma America Corp., Charlotte, North Carolina, answered that question. The MU-V Laser Ex five-axis toolchanger. See toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger." title="CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger." aria-label="Glossary: machining center">machining center and Multus U Laser Ex series lathe are equipped with a Trumpf-powered laser metal deposition system, providing AM and subtractive machining in one CNC machine tool.

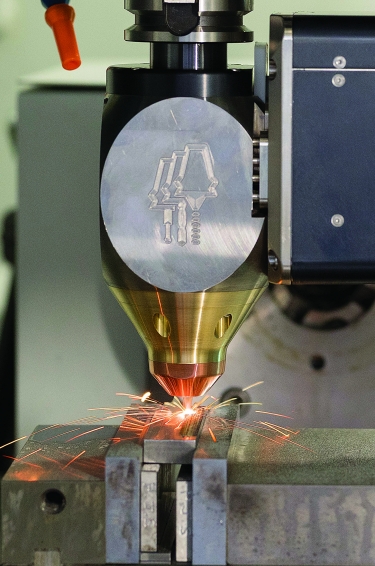

It can be thought of as a cladding process, he said, except that blown powder metal and a laser are used to apply metal rather than wire feedstock and a welding gun. As with other additive processes, laser metal deposition deposits individual layers of material to build part features or even entire workpieces from the bottom up. The thickness and width of these layers depend fully on the machine builder, operating parameters and laser and nozzle configuration, but deposition rates are often 10 to 20 times that of competing powder bed fusion additive technologies, with 6.8 kg/hr. (15 lbs./hr.) or more not uncommon.

The difference is that a hybrid machine allows an operator to finish-machine 3D-printed layers or part sections anytime during the build process. This not only eliminates most secondary operations but permits the creation of part features that otherwise would be impossible to produce with purely AM or subtractive machining. In some cases, the laser also can perform other operations, such as drilling, texturing or hardening.

Despite these mind-blowing possibilities, hybrid isn't for the faint-hearted.

"Just because you're able to build a part doesn't mean you've accomplished your goal," Kingsley said. "Because the workpiece is constantly going from cold to hot and back again, there are metallurgical properties to consider. Also, the CAM people are still playing catch-up, so the programming can be a bit challenging. And you'd better have good involvement from your customer, especially if you're making aerospace or medical parts. It's a completely different way of making parts. You have to learn new techniques and have the time and money for a good bit of testing and process development."

Paul Kingsley of Okuma America prepares the MU-8000V Laser Ex for laser metal deposition. Image courtesy of Okuma America

Adaptive Cruising

Nils Niemeyer, product manager at DMG Mori USA Inc.'s Additive Manufacturing Excellence Center in Hoffman Estates, Illinois, said in-process machine monitoring makes things much easier. That's one reason why the company equipped its Lasertec 3D hybrid five-axis machining centers and turn/mill lathes with melt pool monitoring and sensor-based software tools. (The melt pool is the area where the laser and powder meet.) He said these features aid in preventing build failures while providing more homogeneous metallurgical properties in the completed part.

"We developed AM Monitor to continuously track and manage the additive manufacturing process, allowing the user to adjust laser power and other build parameters in real time or automatically based on different operating conditions," he said. "For instance, there's a camera that monitors temperatures throughout the machine chamber. We have sensors for powder flow, can detect whether there's any material adhering to the nozzle and have a distance sensor that helps to maintain a consistent gap between the nozzle and workpiece. It's like the adaptive cruise control feature on a newer car."

DMG Mori USA also is addressing the aforementioned CAD/CAM gap, working with Siemens NX to develop onboard additive and subtractive programming and simulation software and making a complicated process relatively easy to use. Because of this, Niemeyer said hybrid production is gaining popularity for a range of applications, including fixing damaged turbine blades and worn tooling. In one example, an automaker used the technology to increase die-casting mold life by a factor of five, replacing numerous machining operations and inconsistent manual welding with a single repair process.

Another possibility is the layering of dissimilar materials in a workpiece to enhance its thermal or wear properties, in essence creating a metal sandwich that has been virtually impossible to produce via conventional means.

According to Hybrid Manufacturing Technologies, the company can turn most machining centers into metal 3D printers for a fraction of the cost of a new hybrid CNC machine. Image courtesy of Hybrid Manufacturing Technologies

"Rocket nozzles are another big application," Niemeyer said. "Instead of waiting nine months for a casting, they're simply building up an entire rocket nozzle within a few days. They can quickly prototype multiple designs, select whichever one shows the best performance, and because these are very much end-use parts, they can then go directly into flight-level production."

Ambidextrous Manufacturing

What if a shop doesn't have the budget for a new hybrid machine tool? Well, mainstream hybrid CNCs were pioneered as add-ons to existing CNCs, and Jason Jones, inventor of the Ambit laser cladding head and co-founder of Hybrid Manufacturing Technologies Inc., McKinney, Texas, said his company can turn most machining centers into metal 3D printers for a fraction of the cost of a new hybrid CNC machine.

An Ambit head looks much like any other 40-taper toolholder and fits in any standard automatic toolchanger. Once in a machine spindle, the head connects with an auxiliary high-powered laser and powder metal feeder and can be used in the same manner and for the same purposes as a dedicated hybrid CNC machine.

Hybrid Manufacturing Technologies has taken the hybrid definition one step further, however, by offering Ambit laser drilling and ablating heads, Ambit heads with eddy current and ultrasound capabilities for nondestructive inspection and an Ambit head that 3D-prints polymers at rates "up to 200 times faster than a desktop printer and can be installed in a few hours," Jones said.

He compares the state of 3D printing to the computer industry before the internet.

"Additive gained traction early on as a design tool and prototyping technique and because of that never followed the mainstream manufacturing ethos," Jones said. "Because of this, the different additive technologies that have evolved over the years don't work with one another, they don't talk to one another and even companies that produce multiple types of additive systems wouldn't think of combining them in the same machine. Our goal is to help break those barriers with a system that's cost-effective and easy enough to use that anyone with a CNC machining center can leverage it."

Powder nozzle laser metal deposition technology makes it possible to repair or even build from scratch parts that otherwise would be challenging to produce. Image courtesy of DMG Mori USA

Hybrid Factory

GF Machining Solutions LLC, Lincolnshire, Illinois, also believes in hybrid manufacturing, albeit using a different approach. Jon Carlson, product manager of advanced manufacturing, said the machine tool builder chose not to establish its own 3D-printing capabilities but instead partnered with one of the pioneers of AM, Rock Hill, South Carolina-based 3D Systems Inc. to develop two additive machines.

"The DMP 500 and DMP 350 solutions are for manufacturers that need a scalable, production-grade metal additive system," Carlson said. "We worked with 3D Systems to develop a co-branded,

co-manufactured 500 mm3 (0.03 in.3) printer equipped with three lasers and a quick-change powder management system, then equipped it with a System 3R carrier and an automated handling system. Each of the various components within the DMP 500 communicates with one another, and parts can seamlessly be passed from 3D printer to heat treating to a machining center, a mill/turn lathe, a grinding operation or whatever other post-processing is required."

Like the other companies in this article, GF Machining Solutions, in collaboration with 3D Systems, has addressed the unique challenges to AM. A DMP Monitoring tool set and a vacuum chamber help ensure part quality during the build process while 3DXpert software manages every aspect of the additive workflow — from part design and print preparation to optimization and execution — in the same file format.

"It's a complete modular manufacturing solution," Carlson said, "one where raw powder goes in and finished workpieces come out with minimal human intervention."