All about machining metal 3D-printed parts

All about machining metal 3D-printed parts

Learn the latest on hybrid machine tools, large-scale printed parts and material removal from CTE contributors.

As additive manufacturing and 3D printing of metal and composite parts continue to make inroads into production environments, the need to efficiently and effectively finish-machine parts when that step typically is required gains importance.

One way to do it is with a hybrid machine tool, which performs both additive and subtractive operations. A feature article about these machines by contributing writer Kip Hanson appears on Page 24, and the Look-Ahead column by freelance writer Ken Schnepf covers the MasterPrint 3D printer from Rockford, Illinois-based Ingersoll Machine Tools Inc. The machine 3D-prints and mills extra-large, single-piece composite and metal parts. (See Page 56.)

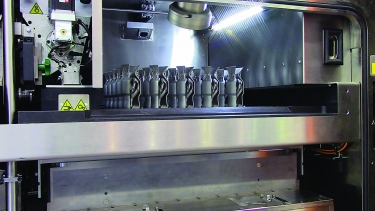

GF Machining Solutions displays the Cut AM 500 horizontal wire EDM at EMO. Image courtesy of A. Richter

Other times, printed parts that require machining are moved to another machine for material removal after the build process. Nonetheless, they first must be cut from the build base, such as with a conventional wire EDM or a bandsaw. An alternative method is from GF Machining Solutions LLC, Lincolnshire, Illinois. The machine tool builder offers the new AgieCharmilles Cut AM 500 horizontal wire EDM for cutting off additively manufactured parts from build bases. The EDM cuts parts without pressure, damage or material alteration, and there is minimal material waste, according to the company. See contributing writer William Leventon's Machine Technology column on Page 16 to learn more.

I had the opportunity to see the Cut AM 500 during a GFMS-sponsored trip to company facilities in Switzerland, which included a tour of its EDM factory in Losone. My fellow travelers included GFMS customers and some of their spouses, as well as a few other members of the trade press. While at the EMO Hannover trade show in Germany, I saw the EDM demonstrated. It was the first time I attended the massive metalworking event.

Another highlight of the trip was the tour and inauguration of the company's new innovation and production center in Biel. After a two-year construction period, the factory for building milling machines was completed in May at a cost of about $100 million. The center has an area of about 44,000 sq. m (473,612 sq. ft.).

"From this new location, we will be able to strengthen our position as a global player and at the same time rely on our Swiss roots," said Pascal Boillat, president of GF Machining Solutions Management SA, during his speech at the event.

In addition to seeing two milling machines that the company has not officially launched yet, the new Uniqua human-machine interface and a presentation about factory digitization, I learned more about GFMS' DMP Flex 350 and DMP Factory 500 metal 3D printers. GFMS designs the machines for industrial applications, and 3D Systems Inc., Rock Hill, South Carolina, handles the printing portion. That sounds like a hybrid partnership.