CAD/CAM software for ultraprecision machining

CAD/CAM software for ultraprecision machining

The primary application for ultraprecision machining is optical-grade surfaces for injection molds, which are used to make contact lenses, LEDs for TVs and head-up displays in military aircraft and luxury cars.

You may have heard of ultraprecision machining (UPM), also known as diamond turning. Its primary application is machining optical-grade surfaces for injection molds, which are used to make contact lenses, LEDs for TVs and head-up displays in fighter aircraft and luxury cars.

UPM can produce complex shapes with submicron tolerances and surface finishes best measured in nanometers, provided the machine is given a commensurately accurate toolpath. That's where Aachen, Germany-based ModuleWorks GmbH comes in.

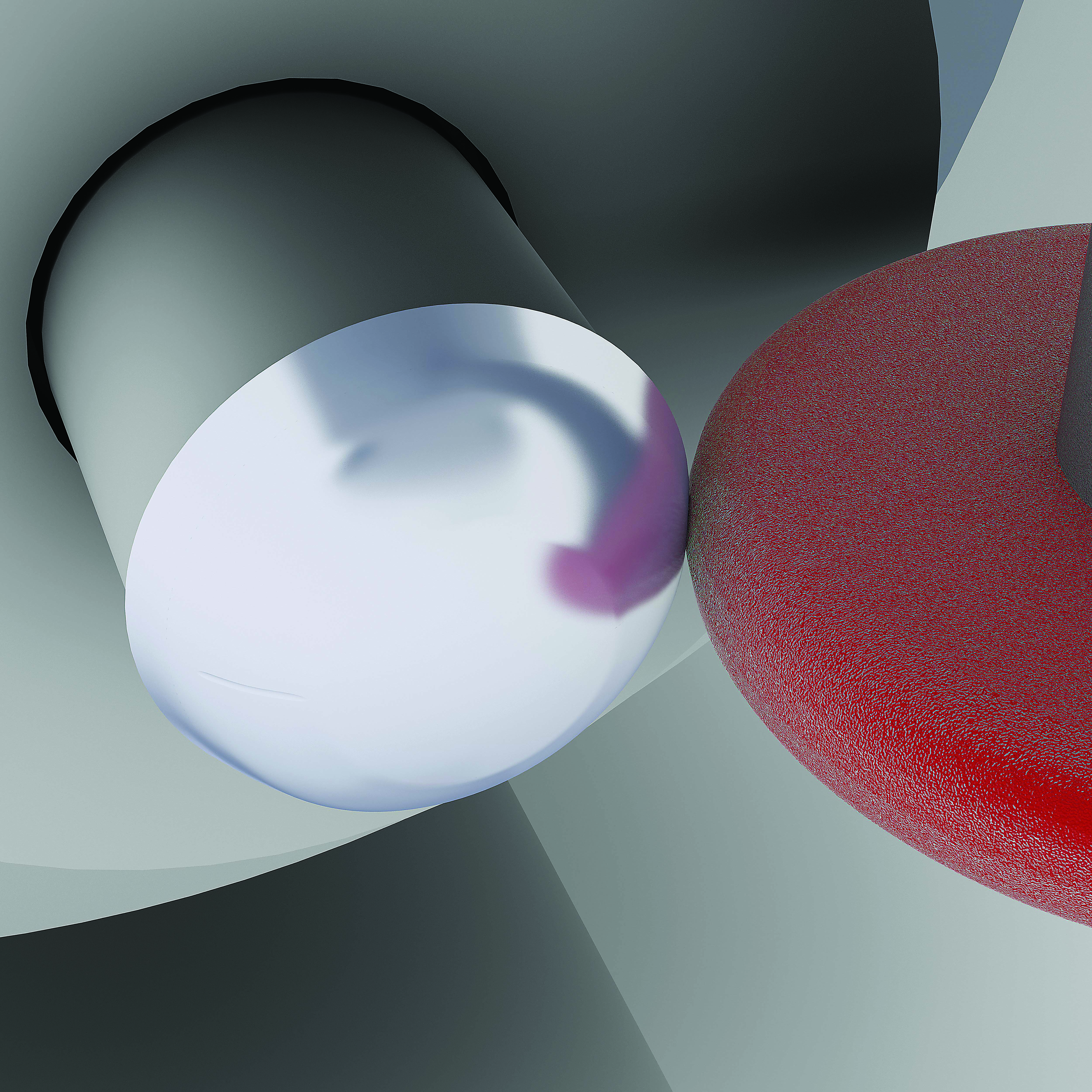

Simulation of a grinding process on a UPM machine. Image courtesy of ModuleWorks.

ModuleWorks team members recently worked on a research project with optics and metrology equipment manufacturer Zeiss International, based in Oberkochen, Germany. The team members were tasked with developing CAD/CAM software that's optimized for UPM. Features include spiral toolpath and zigzag calculations for 2D and 3D optics, advanced nonuniform rational basis spline (NURBS) capabilities, multiple-surface and lens support, and the generation of toolpaths needed to support the "fast tool" and "slow slide servo" technologies employed on these machines.

It wasn't enough to create complex, ultraprecision toolpath data and hope that the UPM machine would produce the desired shape. Zeiss engineers asked for adaptive-software technology that could read and analyze point clouds obtained by measuring machined surfaces and then have the CAM system adjust the toolpaths accordingly.

"You might have metrology data coming from an interferometer, for example, and want to adapt the programmed geometry to compensate for any machine- or process-related deviation," said Lothar Glasmacher, ModuleWorks project director. As for the toolpaths themselves, Glasmacher explained that conventional CAD/CAM systems do not support the cutting patterns needed for UPM, nor are the algorithms accurate enough to meet the geometric requirements of a smartphone camera lens or the optics for an advanced telescope mirror, for example. "This new technology can calculate dimensional values out to the 12th decimal place."

As a result of its work with Zeiss, ModuleWorks offers an "optics component" module for 3D programming of UPM turning, milling and grinding machines. It uses a multiple-threading, 64-bit algorithm for rapid calculation of multimillion toolpath points and supports simulation of multiple spindles and turrets, according to the company. In addition, it can be combined with conventional CAD/CAM software for use with 3-, 4- and 5-axis machine tools.