The challenges of sawing new alloys

The challenges of sawing new alloys

Cutting difficult-to-machine materials is becoming more prevalent but not necessarily less challenging.

Once an oddball-type application, sawing difficult-to-cut workpiece materials has become significantly more common. Manufacturers continue to improve sawing machines, saw blades and coolant, but the machinability of many metals remains an issue. New alloys add to the challenge.

The most difficult-to-cut metals are nickel-base superalloys, according to Jay Gordon, North American sales manager for saws and hand tools at the saw division of The L.S. Starrett Co., Mount Airy, North Carolina. "People are running into them more often."

For bandsaws, Dan Fernandes concurred that the materials with high nickel content, such as Inconel and stainless steel, pose challenges. He's senior product marketing manager for the Lenox brand at Stanley Black & Decker Inc., New Britain, Connecticut. Nickel, cobalt, tungsten, titanium, manganese and chrome are the alloying elements that present the most difficulty for users, he noted.

Image courtesy of Dake

"Overall, nickel is probably the hardest element to work with when it is mixed in with other materials," Fernandes stated. "These alloy combinations each have different levels of impact on the saw and can be difficult to work with based on their percentages."

Similar to bandsaws, the most difficult materials encountered when circular sawing are stainless steel alloys, according to Fernandes. "These materials tend to generate a lot of heat rapidly, which wears out the circular saw tooth and inhibits overall blade life. With these materials, it is difficult for circular saws to duplicate a result, so users typically refrain from working with them under these conditions."

Because these types of "exotic alloys" tend to workharden, Dennis Rice, saw line product manager for Dake Corp., emphasized that it's critical that the cutting speed remains steady. To minimize workhardening, the speed should not increase or slow down during the cut. "You have to treat them with kid gloves the first couple cuts until you're sure of what you have." The Grand Haven, Michigan-based company builds cold saws, vertical and horizontal bandsaws and other machining equipment.

The sawing parameters not only have to remain consistent but must be correct. "With a carbon steel product, you can get away with the feeds and speeds being somewhat out of whack," Gordon said. "But when you get into these difficult alloys, they have to be correct if you want to get any blade life and production out of it."

Mystery Metal

While the compositions of standard alloys, such as Inconel 718 or Hastelloy C-276, are known, part manufacturers also must saw proprietary metals, Gordon noted. "Of course, when it is proprietary, you don't know what's in it."

The Wave Tech process, which Lenox adds to some of its bandsawblades, enhances cutting ability for workhardening materials. Image courtesy of Lenox

To help, he recommended asking the material supplier what the proprietary metal cuts like. "It becomes a lot more dependent on the saw specialist to be able to read chips and determine what may be required."

If the chips look black and blue because of excessive heat and are similar to chips produced on a turning machine, Gordon said something is wrong. Instead, chips should look like steel wool or the familiar curled shape, depending on the application.

"I would say there's a lot of trial and error in some of these materials," he said. "For proprietary materials, you just have to work your way through it and keep adjusting until you arrive at the best solution."

Trial and error, while always an option, can damage blades. To limit blade damage, Fernandes suggested using a program, such as his company's SawCalc, to determine the best way to saw a new proprietary metal based on another material that has similar physical properties.

In addition, consulting with a saw blade manufacturer can generate helpful insights. "Based on what materials need to be cut, what machine the user operates and the size of the blade, one of our technical representatives can calculate the proper feed and speed required to pull an effective chip and meet the customer's goals and requirements," Fernandes stated.

Nonetheless, some metals might be better left to other machining operations. Rice said casehardened Thomson rods, which typically have an outer shell hardness of 60 to 65 HRC, are one example. "The outside is shiny like chrome and only a few thousandths thick, but getting through that few thousandths will tear up the blade big-time. It's hard enough that it'll turn your blade into a butter knife in short order."

Starrett offers Advanz MC5 and MC7 (pictured) carbide-tipped bandsaw blades, which utilize a multiple-chip grind with a high/low tooth sequence. Image courtesy of Starrett

It's not only a metal's composition that can cause fits when sawing. Workpieces with unusual shapes and features also present challenges because they can be difficult to clamp, Rice noted.

"So you have to get creative with your fixturing," he said. "The tighter you can clamp it, the faster you can cut it. The last thing you want is to have the part roll out of the vise when you're halfway through the cut."

Lubricious Chill

Because an extensive amount of heat is generally generated when sawing difficult-to-machine metals, it's important to apply an ample amount of coolant, according to Fernandes. He recommends a water-soluble oil because having an oil in the mix limits the heat.

Besides being able to cool the saw/workpiece interface, the metalworking fluid must provide lubricity for effective chip evacuation, Gordon said. "While an argument can be made for using straight cutting oil, with the advent of soluble oils, semisynthetic and full synthetic cutting fluids, this is typically the least attractive option. The key is a high-quality cutting fluid mixed appropriately for the application that both lubricates and cools."

The SE 5X6 RCT benchtop horizontal bandsaw from Dake features a semiautomatic 2.5-hp motor, gravity down feed and reverse cutting technology. Image courtesy of Dake

Rice emphasized steering clear of oil and selecting a water-soluble coolant instead because it's significantly cleaner and users should "flood it as much as you can."

It's essential not only to apply the right coolant but to do so at the proper concentration as well, as long as the concentration is within a suitable range. "You could always make the concentration a little heavier," Rice said, "and instead of having to mix in more coolant when it evaporates, you just add a little water, and you still have the lubricity you need."

However, if flood coolant isn't an option, spraying a fine mist of vegetable oil on the blade gets the job done when the application is appropriate, he said.

In addition to asking customers whether they use coolant, Rice said one of the first things he asks about is the chip brush, which knocks chips out of the gullet so the blade functions as designed. "They say, 'Yes, we use coolant, and what chip brush?'" Although most saws have one, the chip brush is removed when replacing a blade; many end users feel that it isn't worth the time and effort to replace the brush, he noted. "They put the blade back on, and the brush walks away and is never to be seen again."

However, a chip brush plays a critical role, according to Rice. If a chip is packed into a gullet, it can become welded to the blade. "Then you have a mess trying to clean it out."

Cutting Your Teeth

Blade design is also important when sawing challenging workpieces. For example, to enhance cutting ability when sawing metals that tend to workharden, some of the bandsaw blades from Lenox feature Wave Tech.

"It's a pattern that we add to the back edge of our blades that promotes better tooth penetration and allows you to cut through hardening layers," Fernandes explained.

Available from Starrett are the Advanz MC5 and MC7 carbide-tipped bandsaw blades, which utilize a multiple-chip grind with a high/low tooth sequence to distribute the load over five or seven teeth.

"It allows you to saw more aggressively because the load on each tooth is less than it would be without the progressive tooth grind," Gordon said. "That will also increase your speed. In most cases, the smoothness of the cut increases as well."

"It allows you to push a little harder because each tooth is taking as much load as possible to that chip," Gordon said. "That will also increase your speed. In most cases, the smoothness of the cut increases as well."

Gordon added that Advanz MC5 is more user-friendly whereas Advanz MC7 boosts production. "If an operation has 10 saws and all are heavy-duty machines with no vibration, has the right coolant, good operators and needs to go as hard and as fast as possible, we recommend the MC7," Gordon said. "On the other hand, if a shop has a few saws that are older and operators that are not as well-trained, they would probably be better off with the MC5."

Also, Starrett AMP technology is available on some Starrett bandsaw blades, including Advanz MC5 and MC7 ones, which increases cutting efficiency and blade life, according to the company. A custom back-edge enhancement on the blade generates a rocking motion while cutting, increasing tooth penetration without adding feed pressure. This cutting motion also serves to minimize the surface contact area, increasing blade life when sawing difficult-to-cut alloys.

Regardless of what material is being processed, there's always a trade-off among sawing speed, blade life and surface finish. "Pick the most important because you're not going to have them all," Rice said, noting that the faster the cut, the shorter the blade life whereas imparting a finer surface finish requires reducing the speed.

"To me, finish is the most important," he added. "If it takes me 10 seconds longer to cut a piece, that's 10 seconds. It's going to take me a lot longer than 10 seconds to change a blade because I'm going too fast."

Similar to other machining operations, it's the combination of the blade, saw machine, coolant and other components—as well as knowledge of the workpiece material—that's going to make or break a sawing operation. "The key is focusing in on the whole package and not just the saw," Gordon said.

MQL for Sawing

When circular sawing or bandsawing aluminum and other relatively light metals, minimum-quantity lubrication (MQL) is well-established in the metalworking industry, according to Jim Dyla, president and technical director of AMCOL Corp. The types of parts include castings, extrusions, rolled profiles, plates and billets.

In addition to sawing, the Hazel Park, Michigan-based company manufactures MQL systems for a variety of applications, including machining, forming, piercing and rolling. Regardless of the application, the result is reduced fluid usage with a corresponding reduction in fluid handling and disposal and cleaning fluid-related messes.

Although MQL drastically reduces the amount of needed metalworking fluid, Dyla said a small quantity of lubricant is still required when sawing to aid chip formation. "It's utilizing the best chemistry in very small quantities to get maximum performance."

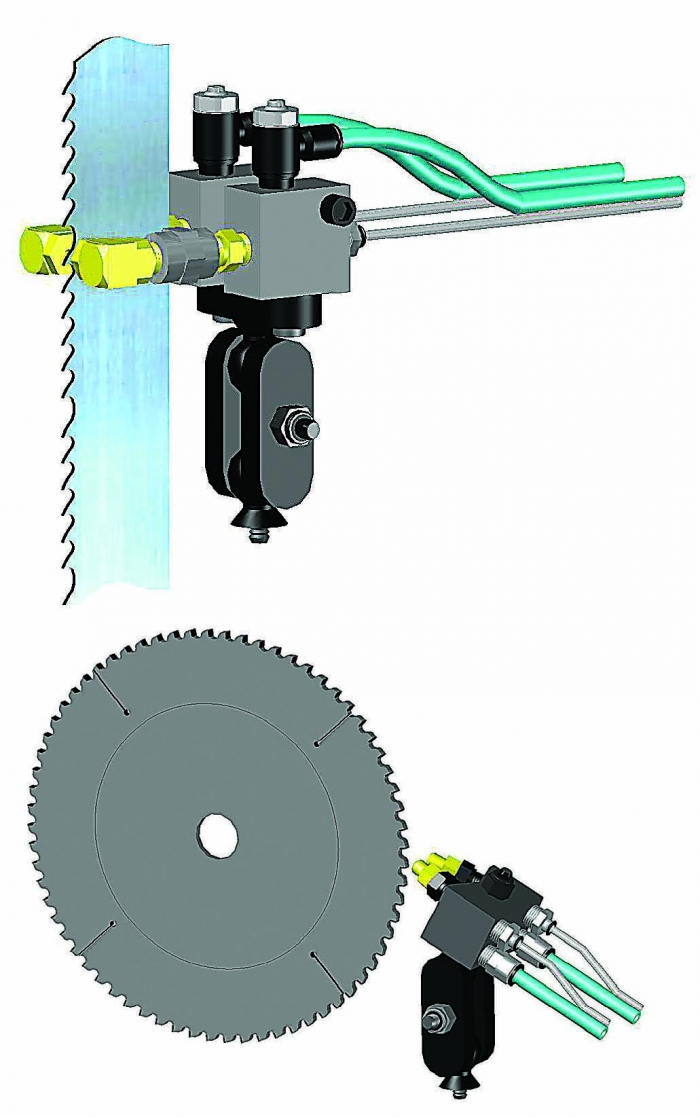

Spray manifolds ensure the appropriate spray angles relative to the cutting edge and are available for a bandsaw (top) and a circular saw (below). Image courtesy of AMCOL

For a positive-displacement pump, he explained that a common setting would repeatedly and reliably dispense one gallon of fluid per 200,000 injection cycles. "Of course, during a cut, you might cycle that once every half-second or so. It depends on the cut time and how many injections and number of spray points to determine use per cut."

The primary base oils used in MQL fluids are synthetic esters, Dyla noted. They have become more complex over the years

because they incorporate additional additives to provide such properties as rust protection, extreme pressure, enhanced lubrication and washability.

"Some of these products have to go through heat treatment, so they have to be heat-treatment compatible," he added.

With the Wet Tip, AMCOL's MQL spray systems mix the liquid and air at the end of the tip, Dyla said. As a result, a high-velocity round spray propels the liquid onto the saw blade rather than creating a less-effective mist or fog. "A mist, as you can picture, doesn't have velocity."

When applying MQL, spray manifolds ensure the appropriate spray angles relative to the cutting edge, Dyla noted. Specialized mounting brackets are available to aid in blade changing and spray manifold maintenance and repair.

According to Dyla, the company's MQL systems are unique because they use an air pressure regulator rather than a needle valve to regulate spray pressure at the tip. "You are able to gage, theoretically, what the flow is at the tip," he said about the design. "This gives you the ability to make an adjustment utilizing a gage rather than a guess."

Because users of MQL systems sometimes tend to feel that more coolant is somehow better, AMCOL offers Smart Metering.

"The Smart Metering concept takes away the ability of the operator to adjust this equipment," Dyla said. "Instead, it goes with settings that are known and accepted to work in these applications. If you overuse the fluids, you can have smoking, oily parts and problems with washability. It's just costing more for fluids."

Although MQL is "by far and away the best application" for sawing nonferrous metals, Dyla said the technology is not nearly as accepted when sawing ferrous alloys and some other metals. To reach those applications, AMCOL continues to incrementally improve its time-tested equipment.

"We're into the fourth generation of updates on this equipment," he said, "where we just keep trying to make it better."