Clever tools for finding an edge

Clever tools for finding an edge

The Shop Operations column in the December 2017 issue of Cutting Tool Engineering covers a few clever tools for finding an edge.

Traditional edge finding on a milling machine is pretty straightforward. Edge finding establishes the milling machine's measuring coordinate system relative to the newly inserted workpiece so the user can perform accurate work. "Picking up an edge" is the general shop description of this operation.

There is an array of mechanical and electronic tools for picking up orthogonal surfaces on a machine tool. Wiggler-type edge finders are common ones (Figure 1). They have a spring-loaded eccentric tip of known size that rotates closer and closer to concentric until it becomes perfectly tangent with the edge under interrogation.

Figure 1. Wiggler-type edge finders have a spring-loaded eccentric tip of known size that rotates closer and closer to concentric until it becomes perfectly tangent with the edge under interrogation. All images: T. Lipton.

Some shop workers debate the proper method to read a wiggler edge finder. The two competing methods are when the edge finder eccentric jumps sideways under the tiniest axis advancement and when, just prior to jumping, both the shank and eccentric are visually running perfectly concentric. The difference in accuracy for each method is very small, with several other factors contributing to the overall accuracy of the edge pickup.

When performing toolmaking or repair work on a milling machine, it is common to establish an accurate datum on nonorthogonal faces or edges of angled surfaces. The traditional wiggler edge finder does not work well for angular situations.

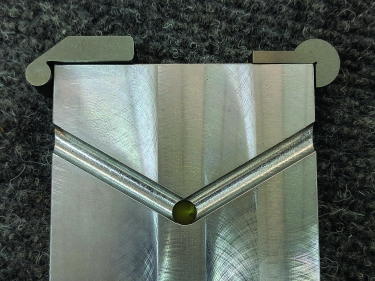

Kern Tool and Pyano, however, developed clever solutions (Figure 2). The round sections of these wire EDM-cut edge finders have a precisely known size. Both can be made from prehardened tool steel for long life and durability. The right-angle model (Kern Tool sine center) has two flat datum surfaces that intersect at the exact center of the round boss.

Figure 2. A Kern-type edge finder (left on surface in front of angled workpiece) and Pyano-type edge finder can be made for angular applications. Note the tiny corner relief at the center of each to clear any burrs on the workpiece.

With a standard wiggler edge finder and a Kern or Pyano-type finder, you can now pick up the precise corner on an angled setup using the standard edge-finding technique. The Kern edge finder also allows calibrating the vertical height of the corner under interrogation by touching off on the top of the known diameter, say, 0.500" (12.7mm), and subtracting one half its diameter. The Kern style works best on acute angles or perpendicular corners.

The Pyano-style edge finder sets the small-diameter circular section exactly tangent to the two intersecting surfaces. Using a little shop math, you can pick up the corner on almost any angle of intersecting surfaces. With the Pyano style, the intersecting surfaces can be open (obtuse) and you still can establish an accurate corner pickup. Both edge finders can establish an accurate corner reference, even if the corner has a small radius or chamfer.

A common application of when you would use such a corner-pickup device is with multiple intersecting holes (Figure 3). The setup and data accuracies are key to generating good results. Combined angular setups are typically sensitive to small positioning and setup errors.

Figure 3. A common application for a Pyano or Kern edge finder is with multiple intersecting holes.

Figure 3 shows three holes intersecting in one location, with the center hole forming a smooth tangent radius between the two angled ports. This is possible only if the three different setups required for this example are performed carefully and accurately.

The angle of the working surface must be known or set accurately with the Pyano edge finder. Because its tangent position varies with the angle of the work surface, that angle needs to be known with some certainty to determine the exact corner position. This is usually not a problem because the angle is deliberately established as part of the work setup. It should be noted that either of these edge finders works for round or circular work.

Unfortunately, these clever edge finders are not commercially available, to my knowledge, but both are easy to make on a wire EDM. The able folks who inhabit machine shops can even make them without a wire EDM.

The Kern-type edge finder can be made from an accurately sized round with a 90° groove machined or ground along its axis. Take care when cutting the groove to the precise centerline. In addition, make sure to add a small relief at the centerline to allow burrs on the part to clear.

The Pyano-type edge finder can be made with a small piece of steel ground flat and an accurately sized dowel or gage pin soldered or glued with industrial cyanoacrylate, such as Locktite 380. Try them; you'll like them.