Component cleanliness requires effort throughout manufacturing process

Component cleanliness requires effort throughout manufacturing process

Specifications for particulate and film-residue cleanliness are a matter of course for many machined components. In addition to the parts cleaning procedure, manufacturers must consider the entire process chain when seeking to efficiently achieve and maintain the required level of cleanliness.

Specifications for particulate and film-residue cleanliness are a matter of course for many machined components. In addition to the parts cleaning procedure, manufacturers must consider the entire process chain when seeking to efficiently achieve and maintain the required level of cleanliness.

Even the tiniest particle or a microns-thick film residue can negatively impact later processes, part quality and the functionality of the finished product. For example, cutting tools are often coated with hard materials, such as diamond-like carbon, to improve their performance and service life. Depositing these coatings requires a high level of surface cleanliness, and any particulate or trace of film-forming residue will degrade the adhesion of the coating to the tool substrate, which can cause premature tool failure.

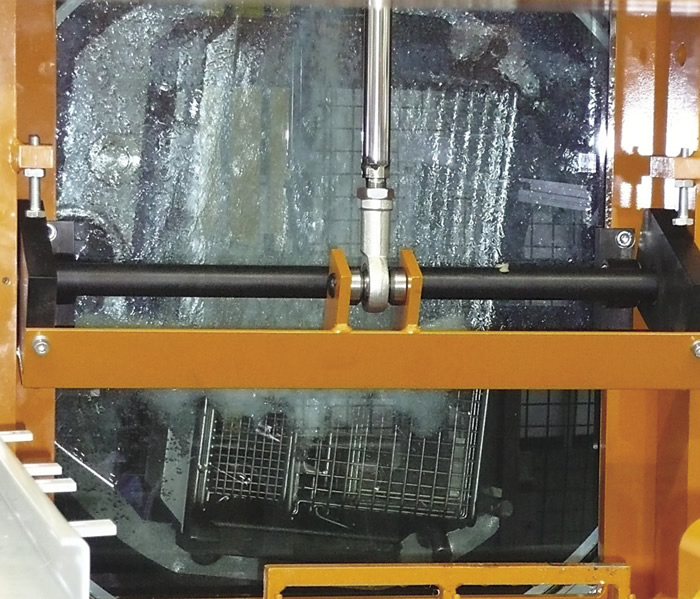

Solvent cleaning systems that are commonly used to remove nonpolar contaminants are equipped with an integrated distillation unit for continuous solvent conditioning. Image courtesy Höckh Metall-Reinigungsanlagen.

"Technical cleanliness" is, therefore, a quality consideration for many components, and design drawings often specify a cleanliness level. These specifications generally can only be met with considerable capital investments in industrial parts cleaning equipment. This includes units for maintaining the quality of the cleaning bath, filtration systems to remove particulates brought into the cleaning system, and rinsing fluids and systems for removing film-like contaminants, such as oil and grease. Among the systems available to maintain bath quality are vapor distillation, bag filters, multiple-tube filters, magnet separators and coalescence separators. The system selected is determined by part-cleanliness requirements, type and amount of impurities and the cleaning agent, whether a solvent or aqueous cleaner.

However, equipment alone is no guarantee of reliable and cost-effective cleaning.

Let the Scrubbing Begin

Cleanliness actually starts with the component-design phase. This is when part geometry and the individual steps in the manufacturing chain, such as turning, milling and grinding, are defined. This also determines the effort that's necessary to clean parts. For example, a through-hole is easier to clean than a blind-hole, and designing a part with rounded inner contours instead of corners and edges reduces the amount of dirt that collects inside the part. This design feature also promotes laminar flow through the workpiece during cleaning, which prevents the formation of eddies and the resulting particle deposits. Surface finish influences a manufacturer's ability to clean a part, too, because a smooth surface retains less dirt than a rough or porous one.

A change in contaminant input or modification of the coolant formulation can lead to insufficient conditioning of the cleaning solution and insufficient cleaning results. Image courtesy Karl Roll.

It's also important to control the amount of contaminant build-up. The less oil, grease and other contaminants that adhere to parts, the quicker and easier it is to achieve the required cleanliness.

In multiple-step machining operations, intermediate cleaning processes prevent residue from accumulating and lubricants and coolants from mixing or drying, all of which can lead to problems when cleaning. Intermediate cleaning also prevents machining oil or coolant residue from acting like a magnet and attracting dirt from the shop environment.

Finally, proper preparation and filtering of the coolant or lubricant prevents contaminants already removed from parts from being redeposited on clean parts.

Fine-Tuning the Process

In metalworking, almost all parts cleaning tasks can be performed with wet chemicals. The effectiveness of the process used, and, therefore, the outcome in terms of quality, efficiency and stability, are primarily determined by the dissolving capacity of the chosen cleaning medium.

Aqueous cleaners and solvents are customarily used. Water-based media are available in pH-neutral, alkaline and acidic formulations.

For solvents, a distinction is generally made between chlorinated hydrocarbons, nonhalogenated hydrocarbons and modified alcohols. The latter exhibit hydrophilic and lipophilic properties, which are advantageous because they remove polar and nonpolar contaminants. Modified alcohols are an alternative to chlorinated hydrocarbons, hydrocarbons and aqueous cleaners. However, cleaning trials are recommended to ensure they provide the required level of cleanliness.

Cleaning containers made of round stainless steel wire provide good and complete access to the parts by the cleaning medium and cleaning mechanism, such as ultrasound waves. Image courtesy Metallform Wächter.

When choosing a cleaning medium, the basic chemical principle "like dissolves like" applies. In other words, for a mineral oil-based (nonpolar) contaminant, such as cutting oil, grease or wax, a solvent is generally the correct choice. Chips and particles lose their grip on the surface once the oil is removed.

Solvents are employed in closed-loop cleaning systems that comply with directives for volatile organic compounds. The cleaning process can be divided into several phases, such as cleaning, vapor degreasing, rinsing and drying. (For more about vapor degreasing, see the sidebar on this page.) Parts cleaning machines with multiple fluid tanks make it possible to integrate and use different solvent tanks. For example, a machine can be set up for preliminary cleaning, fine cleaning and corrosion protection.

Modern cleaning systems are equipped with an integrated distillation unit, which continuously removes oils and greases from the solvent. Additionally, these machines offer a filtration unit equipped with bag or multiple-tube filters for removing particulates like swarf, chips and burrs. The unit is usually integrated into fluid loops. When the solvent removes large quantities of metal particles from the parts, a magnetic separator can be integrated into the filtration system. These features enable the solvent to be used in a closed-loop system and assure consistent cleaning quality and low solvent consumption.

Polar Plunge

For water-based (polar) contaminants, such as coolant and lubricant emulsions, polishing pastes, salts, wear particles and other solids, water-based cleaning agents are generally employed. Cleaning tests with the aqueous cleaning agent are recommended to verify material compatibility and that the required results can be achieved.

To ensure consistent cleaning quality for aqueous processes, it is necessary to regularly monitor various parameters, such as the cleaner's concentration level, temperature, rinse water quality and filter status.

For monitoring the cleaning performance of an aqueous bath, sensor-based measuring systems developed for cleaning processes are available. These devices detect and document the extent of particulate and oil contamination in the bath and reliably indicate when the bath must be changed. Other parameters relevant to the process, such as pressure, temperature, pH value and specific conductance, can also be integrated to generate a complete process picture.

In closed packages, volatile-corrosion-inhibitor packaging materials, such as powders, granulates, fluids, waterproof films and foams, generate a gaseous phase that protects against corrosion. Image courtesy Hermann Bantleon.

Continuous removal of contaminants from the cleaning bath is necessary to prevent them from being redeposited on the cleaned parts. This is achieved by bath maintenance measures based on the type and volume of contaminants. A change in contaminant input, such as from a coolant formulation that has been modified by its manufacturer, a different processing medium or a higher volume of contaminant, can cause inadequate conditioning of the cleaning solution and insufficient cleaning results.

The container that holds parts to be cleaned also plays an important role in the quality and efficiency of the cleaning process. Regardless of whether parts are cleaned in bulk or individually, it's recommended that cleaning containers be made of rust-free, round, stainless steel wire. These provide effective, complete access to the parts by the cleaning medium and the cleaning method, such as ultrasound waves or spray.

Another key aspect is the positioning of the part in the carrier; it must positioned so as to allow critical areas of the component to be accessed directly and treated in a targeted way.

Handling and Packaging

Once parts leave the cleaning facility, their cleanliness must be maintained throughout all subsequent steps, such as picking, inspection, transport, storage and packaging. Simply enclosing or covering the area where cleaned parts are removed from the cleaning system protects them from recontamination by environmental impurities, such as dust and oleiferous air.

For parts with high cleanliness requirements, it is advisable to perform parts removal, inspection and packaging in a clean area or clean room with properly trained and equipped personnel. Volatile-corrosion-inhibitor packaging materials are available to protect cleaned parts from corrosion. These packaging materials create a corrosion-proof atmosphere inside a package while providing protection from outside contamination.

When all elements of the parts cleaning process are properly in place and in harmony with the overall production chain, dirt and debris are rendered defenseless.

International Trade Fair Addresses Parts Cleaning

Which processes enable reliable and efficient parts cleaning? What should be considered when selecting a cleaning medium? How can the targeted degree of cleanliness be achieved? Answers to these and many other questions can be found at parts2clean, a trade fair for industrial cleaning of parts and surfaces that takes place May 31 to June 2, 2016, at the Stuttgart Exhibition Center in Germany. For more information, visit www.parts2.clean.de.

Contamination elimination

When parts must be cleaned of oil and particles prior to surface treatment, such as coating or hardening, vapor degreasing is an effective option. Vapor degreasing scrubs a part with hot solvent vapors, which condense on the part at a sufficient rate to form a liquid flow. This dissolves and washes the contamination away as the condensed solvent drains via gravity.

Vapor degreasing removes contaminants from parts machined and stamped using oil-based coolants more effectively than a water-based system, according to Sandro Siminovich, product line manager for Dürr Ecoclean Inc., a Southfield, Mich., manufacturer of vapor degreasing and other parts cleaning equipment. Applications include cutting tool inserts, medical device and aerospace and automotive parts, such as those found in airbag, braking and fuel-injection systems.

He explained that modern vapor degreasing is performed in a closed-loop system that's completely under vacuum, so virtually no solvent emissions escape into the atmosphere. "It's very environmentally friendly," Siminovich said. Solvent is constantly regenerated inside a vapor degreasing machine during use, but the solvent needs replenishment because the waste oil from the cleaned parts contains a small percentage of solvent.

Siminovich added that the vacuum created in a work chamber also enables internal part features, such as blind-holes, to be thoroughly cleaned of oil and particulate matter. "If you don't remove the air, you can create a pocket and the solvent is not going to reach [all] of the blind-holes," he said. "By having the vacuum, you make sure that all areas are accessible."

A typical vapor degreasing system has one, two or three stages of liquid cleaning, Siminovich explained, followed by vapor degreasing and a drying process to ensure all the solvent vapor—solvent in its purest form—is removed from the work chamber and parts. Depending on the application, a system can include other stages, such as one for depositing a rust inhibitor on parts.

The EcoCCore solvent-based system from Dürr Ecoclean is suitable for high-volume and high-throughput industrial parts cleaning. Image courtesy Dürr Ecoclean.

Vapor degreasing is suitable for cleaning everything from microparts, such as stents and watch gears, to large parts like pipes for the oil industry, Siminovich said. The bigger parts might require a special machine, but standard equipment is available for parts up to about 24.5" (670mm) long, and parts can be processed in batches.

"It can be from one to a million parts processed at one time," he said. "It depends on the size of the parts and the size of the work chamber."

When considering a vapor degreasing system, Siminovich emphasized that part manufacturers should consider at least four areas: the type of contamination to be removed; the specified cleanliness level that's required; throughput requirements, including part size and quantity and how many hours the machine needs to run each day; and part geometry and handling, such as fixturing or rotation requirements.

In addition, it's critical to examine the entire process chain and not isolate parts washing. "You need to look at what is happening before [washing] and what is happening after," he said, "so you make a system that is compatible with both sides."

A standard, closed-loop vapor degreasing machine costs from $100,000 to $400,000, and payback is typically from 2 to 2½ years, according to Siminovich.

For more information about Dürr Ecoclean, call (248) 450-2000 or visit www.durr-ecoclean.com.

—Alan Richter