Constant chip load machining

Constant chip load machining

A Seattle shop reaps the benefits of constant chip load machining, according to the October Get With The Program column in Cutting Tool Engineering magazine.

Most people's eyes glaze over at the mere mention of radial chip thinning (RCT), but it is important. Essentially, when machining at step-overs of 50 percent or less, everything most of us over 30 have been taught about CNC machining parameters goes out the window.

Decreasing the step-over can be effective because it:

- reduces stresses on the tool, the part and the machine;

- allows up to the entire flute length of an endmill to be used for full depth cutting;

- requires cutting at a higher metal-removal rate to effectively evacuate chips and, therefore, heat; and

- substantially reduces tool wear and associated costs as a result.

To use RCT effectively, all you need is a good machine, good CAM software, appropriate carbide cutting tools and a basic knowledge of the appropriate settings for a given machine, workpiece material and cutting tool combination. You can vary the feeds, speeds and tool engagement as much as you want, as long as you keep the toolmakers' recommended chip load constant. The benefits of constant chip load machining are far greater than the sum of the individual cost benefits.

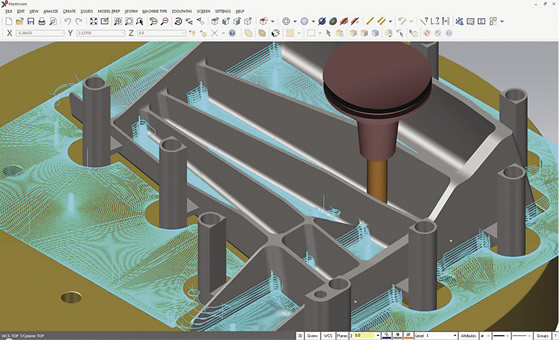

High-speed machining using Mastercam's Dynamic Motion Technology is shown here in combination with the advanced tabs fixturing for fast transitions between top and bottom side machining. This allowed Five Axis Industries to improve in its metal-removal rates by up to 70 percent. Image courtesy CNC Software.

Five Axis Industries, Seattle, is a job shop that specializes in complex, multiple-axis machining of titanium, Inconel and the hardest grades of stainless steel. The company started as a hobby shop for the owner to produce advanced propellers for his race boat, but soon racing-boat enthusiasts throughout the world were buying them. The expertise gained in adapting 5-axis machining to making propellers led to additional opportunities for making geometrically complex parts for aerospace and other industries.

In 2013, the company retained Jason Koger as a programming consultant. His mission was to use his extensive experience with Mastercam CAM software from CNC Software Inc., Tolland, Conn., to devise efficient machining strategies that would reduce costs and enhance competitiveness.

An early project he worked on was a difficult part that was consuming 8 hours of machining time and leaving a trail of broken cutters in its wake. Koger was familiar with Mastercam's Dynamic Motion technology, a version of constant chip load machining, and he applied it to the job.

"The goal was to make these parts as fast as possible without breaking a cutter," said Erik Ellstrom, president. "The machine cycle was reduced to a little over 3 hours and there were no broken cutters."

Today, Five Axis Industries applies this roughing strategy at every possible opportunity.

"We were spending up to $150,000 a month on cutters a couple years ago," Ellstrom said. "Using Dynamic Motion to change our machining strategies, we have brought those costs down to $35,000 in June of 2015. Even though we are doing much higher volumes of work, during the past 12 months we have reduced overall cutter costs by more than 75 percent."

Part of the cutter cost reduction is because of slower tool wear. For roughing, Five Axis Industries typically applies endmills with minimal step-overs and the DOC can be up to the full flute length. This spreads the wear over more surface area, so a tool lasts up to four times longer.

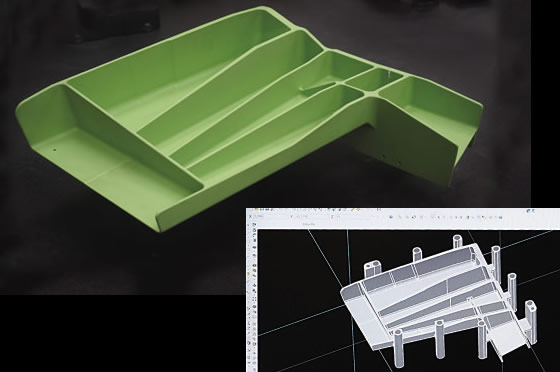

Five Axis Industries has improved mrr by about 60 to 70 percent on a part like this by incorporating Mastercam's Dynamic Motion technology, which enables cutting with full-flute engagement at high speeds and a constant chip load. Image courtesy Five Axis Industries.

Because Dynamic Motion reduces lateral cutting stresses, the shop can reduce the size of the tool required for any given operation. "A ½ " carbide endmill might cost $60, but if you jump to ¾ ", the tool takes an exponential leap to $140," Ellstrom said. "So by using the high-speed Dynamic Motion toolpath, we can get away with a smaller cutter that would have the same life, but is nearly 60 percent less expensive."

Smaller cutters also impart finer surface finishes. Five Axis Industries takes advantage of this as often as possible to rough and finish with the same tool. Ellstrom said, "We were setting up 30 tools to do a typical job and are now setting up about 20." This reduces setup times by about 1 hour and eliminates about 20 tool changes, saving 15 seconds for each change.

Although reducing tool costs was its primary objective, the company soon learned that Dynamic Motion toolpaths also improved the mrr. He estimated that using Dynamic Motion for roughing and applying the same tool for finishing cut run times by 60 to 70 percent.

"Based on the material we are running and the cutter specs, we know what the max chip load is, so we will run as fast as the carbide tool will allow us and vary the engagement to keep the chip load constant," Ellstrom said. "With titanium, we'll run 425 sfm with a 0.0067 " chip, using a 5-flute endmill. With this approach, a 2-hour job can easily become a 40-minute job."

You can get a good starting point for your chip load data in this calculator.

Five Axis Industries maximizes its spindle hours by running equipment unattended through the evening hours when it can at the same parameters it does during the day. The toolpaths based on Dynamic Motion technology are so reliable that there is little concern that a broken tool will interrupt lights-out production. "If a tool breaks, then we did something wrong, not the software," Ellstrom said.