Cool tools

Cool tools

New tools from Kyocera SGS could make a splash in your shop.

When the job calls for going deep, these new tools could make a splash in your shop.

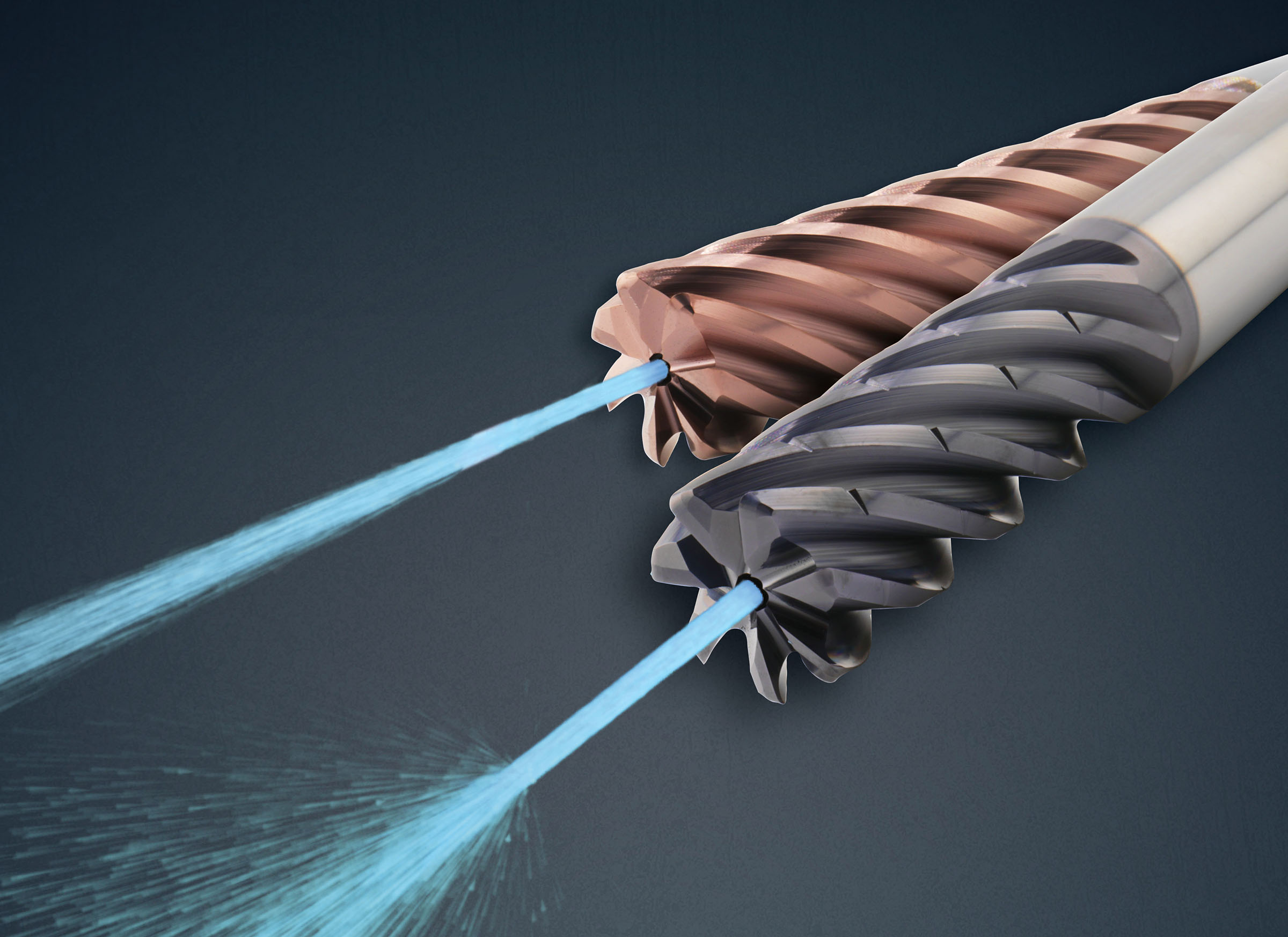

The tools are an extension of the line of H-Carb seven-flute carbide endmills from Kyocera SGS Precision Tools Inc. in Cuyahoga Falls, Ohio. What sets the new offerings apart is a central hole that delivers coolant to the cutting zone in order to reduce wear and improve chip evacuation in deep pocketing and slotting applications.

The 400-plus new coolant-through options also feature a standard chip-breaker profile to facilitate chip flow. But even when using a chip-breaker tool for deep pocketing, "some of those chips can still be a little bit heavy and hard to evacuate from the pocket," noted Jake Rutherford, a research and development engineer at Kyocera SGS Precision Tools. "The through-coolant really helps get that material out of there so you're not recutting chips and causing premature damage to your tool."

Image courtesy of Kyocera SGS Precision Tools Inc.

According to Rutherford, the main advantage of the coolant-through feature is probably the boost it gives to a tool's ramping capabilities. "With a helical ramp, there's a lot of heat down at the bottom where the cutting is actually going on," he explained. "The deeper you get, the more critical that coolant flow becomes and the more difficult it is to get coolant to that cutting edge."

By delivering large amounts of coolant to the place where it's needed, the coolant-through tools allow shops to use up to six times greater ramp angles than those recommended for tools lacking this feature, Rutherford said. "And running at that steeper angle allows you to get to the bottom of your pocket faster, reducing your cycle time."

Available in three lengths of cut (2.5xD, 3xD and 4xD), H-Carb tools are designed for improved rigidity as well as chip flow. "We vary the design based on the flute length in order to [prevent] the increased deflection you commonly see at longer lengths of cut," Rutherford noted. "The longer the flute length, the more rigid the tool is through a heavier core."

The H-Carb's seven-flute design produces excellent finishes at higher feed and speed rates than five- and six-flute tools, according to Kyocera. In addition, the line includes a wide range of square-end and corner-radii options to meet a variety of machining requirements.

H-Carb tools are suitable for cutting steel, stainless steel and cast iron, as well as titanium and high-temperature alloys. However, the tools should be limited to cutting materials with a hardness that does not exceed 45 HRC. For materials such as hardened steel, "we would point the customer to more of a mold and die-style tool with a geometry that is optimized for that material," Rutherford said.

For increased wear and abrasion resistance, tools in the expanded H-Carb line come with either Ti-Namite-A or Ti-Namite-M coating technology. The Ti-Namite-A coating is optimized for cutting stainless steels and high-temperature alloys, while Ti-Namite-M is aimed at applications involving steels, cast irons and titanium.

The new endmills are a good fit for deep-axial trochoidal and high-speed machining processes in a variety of industries, including aerospace, medical, power generation, automotive and foundry, according to Kyocera. "We typically don't make application-specific tools because we don't want to pigeonhole ourselves," Rutherford said. "Anywhere you have a deep pocket and you're able to apply a trochoidal-style tool path, that's where these tools excel."