Cutting benefits of ceramic and cermet tools

Cutting benefits of ceramic and cermet tools

Ceramic and cermet cutting tools offer productivity-boosting benefits when the application is appropriate.

"Everyone's image of ceramic is a ceramic coffee mug that if you drop it, it shatters," said Brian Wilshire. "How in the world can you cut metal with it?"

But as technical center manager for Kyocera Precision Tools Inc., Wilshire is quite familiar with the metalcutting capabilities of ceramic composite, as well as cermet, tools. The Hendersonville, N.C.-based toolmaker's offerings include ceramic and cermet inserts for milling and turning. The types of ceramic tool materials include Al2O3, silicon nitride and silicon aluminum oxynitride (SiAlON).

NTK Cutting Tools USA

Because SiN and SiAlON are relatively tough ceramics, especially at elevated temperatures, tools made of these materials are best-suited for roughing cast iron and heat-resistant superalloys (HRSAs), Wilshire said. "The Al2O3-based ceramics are still pretty brittle, so those are mainly for hard turning with no interruptions or for finishing cast iron."

According to Steve Howard, marketing and engineering manager for NTK Cutting Tools USA, Wixom, Mich., SiN-based ceramic grades, such as NTK SX6 and SP9, have twice the fracture toughness of alumina-based ceramics. This level of toughness enables turning and milling cast iron at speeds up to 3,000 sfm.

In addition, NTK's SiAlON grades blend the strength of silicon-nitride ceramic with the heat and wear resistance of alumina oxide, Howard said. "NTK's five grades, with SX3 being the newest, feature excellent strength and thermal shock resistance under high temperatures, as well as notching resistance, which are ideal characteristics for high-speed machining of heat-resistant alloys common in aerospace, power generation and oil and gas industries."

NTK's five grades of black ceramics—alumina with hard carbide added to improve toughness and hardness—have a high-hot hardness and low plasticity to turn steel, chilled or ductile iron rolls and some powdered metals as hard as 62 HRC, Howard said. "Our finest grain structure—ZC4 grade—can perform finishing cuts on steels up to 70 HRC. These ceramics are cost-effective alternatives for applications previously limited to CBNs."

Like the name implies, cermet combines ceramic elements (such as TiC, TiCN and molybdenum carbide) with metallic binders (such as nickel, as well as molybdenum and cobalt to a lesser degree), Wilshire noted.

Cermet is more brittle than tungsten carbide, so cermet cutting tools are susceptible to chipping and breaking when stressed while taking heavy cuts, he said. As a result, more users consider cermet tools suitable for finishing only at a 0.010" to 0.020" DOC. However, Kyocera has developed cermet tools that can take a 0.060" to 0.080" DOC in "clean" material.

"If you have interruptions or scale, carbide is still going to be the way to go there," he said.

Technical Developments

Although cermet and ceramic cutting tools have a long history, toolmakers continue to make advancements. One such advancement at Kyocera creates a gradient in cermet material via a combination of techniques employed during the insert pressing and sintering processes, Wilshire said. "We call those 'hybrid cermets' because they offer a hard outer layer and more toughness in the center."

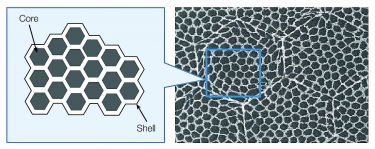

Kyocera also combines tough and hard in ceramic inserts. Wilshire explained that the company is able to produce a honeycomb-shaped grain structure in which the hexagon shape that forms the honeycomb is made of tougher ceramic than the harder central core that it surrounds. If the center part develops a crack, the crack will not propagate beyond the shell and cause the insert to break.

The MC275 Walter Prototyp ceramic milling cutter has a solid-carbide shank. Image courtesy of Walter USA

"It competes with the whisker material," he said.

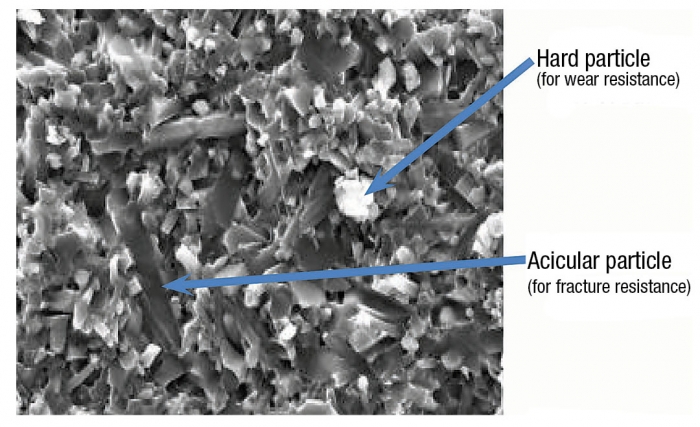

Kyocera does not produce inserts made of whisker-reinforced ceramic but, according to Wilshire, offers a second technology to improve the fracture resistance of ceramic similar to one reinforced with SiC crystals. In the company's newer SiAlON materials, the grain structure is manipulated to cause some of the grains to become needle-shaped, which functions like whiskers. "During the sintering process, the crystals actually grow," he said. The structure also includes hard particles for wear resistance.

With Reinforcements

Greenleaf Corp., on the other hand, is well-known for its whisker-reinforced ceramics, having introduced the uncoated WG-300 grade in 1985, said Jan Andersson, global director of the TechTeam and marketing for the Saegertown, Pa., toolmaker. Greenleaf later introduced the WG-600 coated whisker-reinforced ceramic followed by the WG-700, which has a different substrate and a nanostructured coating.

"There are a lot of applications where whisker-reinforced ceramics are still—by far—the best solution," Andersson said.

A more recent development from Greenleaf is its XYSTIN-1 phase-toughened ceramic. It is a thermally stable, whisker- and particulate-toughened SiN with almost twice the strength of any other commercially available ceramic tool from Greenleaf, the company reports.

In theory, all ceramic tools remove metal by raising the temperature in the cutting zone to a level that causes the material to plasticize, which makes it easier to machine, Andersson said. Without plasticization, tool edge chipping and top and flank slicing can occur.

"That's when you see catastrophic failures," he added. "But once we get to XYSTIN-1, the theory goes out the door."

According to Andersson, the phase-toughened ceramic's high strength enables an XYSTIN-1 tool to efficiently cut without the need for full plasticization to occur. This ability is beneficial when turning a large and heavy or imbalanced part that's not practical to spin at high speed. For instance, when machining an imbalanced part made of Inconel 718 with a hardness of 46 to 48 HRC, the low-end cutting speed needed for ceramics to plasticize the material is about 550 to 600 sfm. In contrast, an XYSTIN-1 insert can run at 350 to 400 sfm whereas a carbide tool would reach only 150 to 180 sfm.

"I can take the middle road and gain the productivity that you get from ceramics without being forced to hit 600 sfm," Andersson said.

According to NTK Cutting Tools, its BIDEMICS—JX1, JX2 and a new release at IMTS—represent the latest advanced composite material for effectively machining HRSAs since the introduction of whisker ceramics. The material's unique physical characteristics provide exceptional tool life, impart fine surface finishes and enable cutting speeds up to 1,600 sfm.

Head Strong

Another type of "hybrid" tool is available from Walter USA LLC, Waukesha, Wis. The MC275/MC075 Walter Prototyp ceramic milling cutters have a ceramic head brazed onto a solid-carbide shank. The toolmaker also offers a design with interchangeable ceramic heads that can be screwed onto a shank. The target application is milling HRSAs.

The MC275 features a universal geometry for multiple purposes while the MC075 has a geometry for achieving high feeds in challenging materials. Both designs can achieve cutting speeds up to 3,300 sfm. "We are almost reaching values that are usually seen in aluminum machining, with a feed of up to 380 ipm," said Stefan Benkóczy, component manager of aerospace and business application development for Tübingen, Germany-headquartered Walter AG.

Kyocera manipulates the grain structure in some of its newer SiAlON ceramic turning grades, such as KS6040, to cause some of the particles to become acicular, or needle-shaped, and function like fracture-resistant whiskers. Image courtesy of Kyocera Precision Tools

In addition, Walter makes cermet inserts for turning. However, because HRSAs often contain nickel, a cermet cutting tool with a nickel binder is not suitable for machining a nickel-base superalloy.

"If the cutting grade has cobalt and the workpiece has cobalt, then you get a lot of built-up edge and the cobalt gets washed out of the cutting edge, the carbide grains get loose, the edge becomes chipped and the tool won't last very long," Benkóczy said.

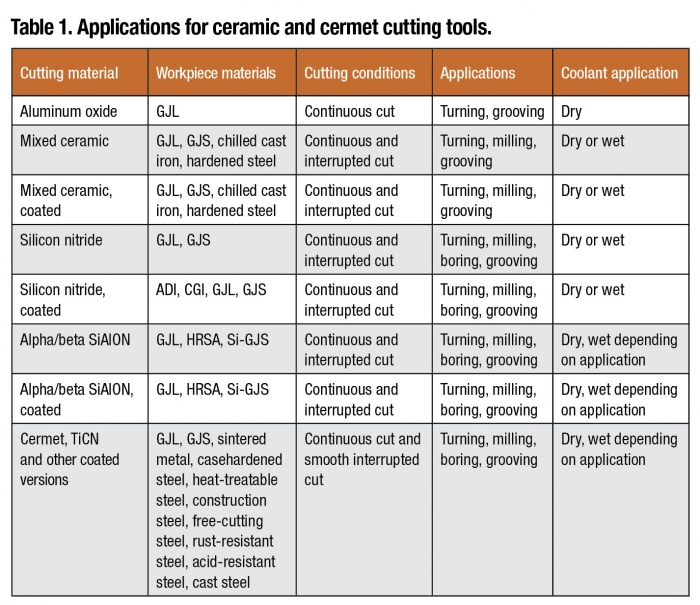

When the application is appropriate, cermet cutting tools exhibit significantly high cutting-edge stability and moderate toughness, stated Joachim Beck, marketing manager for CeramTec GmbH, Plochingen, Germany. (CeramTec North America Corp. is based in Laurens, S.C.) These properties make cermets well-suited for finishing and fine finishing a variety of workpiece materials, including ductile cast iron, free-machining steel and casehardening steels. Suitable applications include turning, milling, continuous-cut boring and smooth interrupted cuts. (See Table 1.)

In the Rough

Ceramic cutting tools are just for roughing, according to Benkóczy. Because of the severe tool wear ceramic tools experience, such as chipping of the cutting edge and a significant reduction in the tool radius, they can continue to perform roughing but are not suitable for finishing.

"The finishing we do with carbide, and the roughing we do with ceramic," he said.

That choice of cutting tool materials is particularly prevalent in the aerospace industry, such as when machining an HRSA engine part, because the production process is usually certified and cannot be easily changed, Benkóczy said.

ADI = austempered ductile iron; CGI = compact graphite iron; GJL = gray cast iron; GJS = ductile cast iron; HRSA = heat-resistant superalloys; Si-GJS = ductile cast iron with high-content silicon. Image courtesy of CeramTec

"Certification costs are immense for aerospace engines," he said. "If an engine is being started from scratch or when a new line is added or something major changes, then, of course, it's an open box and new ideas can be put in."

Greenleaf's Andersson concurred that Federal Aviation Administration regulations and certifications may prevent anything but carbide tools from being used for an aerospace finishing application but emphasized that ceramic tools are not just for roughing. The traditional mind-set sees ceramics as highly effective for roughing when there are no interruptions and the setup is stable.

"There's a lot of history that we're constantly working to change the mind-set about," he said, adding that aerospace parts manufacturers are realizing that ceramic tools can impart fine surface finishes and are more than acceptable for finishing HRSA engine parts.

Cool and Coated

When milling with a ceramic tool, Benkóczy recommends dry machining to avoid increasing the thermal shock on the cutting edge as it transitions back and forth from its brief engagement with the workpiece to a longer airtime. In addition to not decreasing tool life, dry machining avoids having to clean the mess that coolant can create and exposing workers to metalworking fluid chemicals. Pressurized air, however, can be applied to help clear the chips from the cutting zone.

"If you're unlucky, you may even increase workhardening in the workpiece material," he said about coolant application.

Applying coolant when roughing cast iron, though, can help, Kyocera's Wilshire said. "A lot of shops like to run coolant just to keep the dust particles down."

When turning with ceramic tools, Andersson suggests using coolant. "If you don't," he said, "as you engage continuously, you will have a continuous increase in temperature. You want to have a high temperature—but a high, even temperature. That's why you always use coolant when it comes to turning."

For cermet cutters, Wilshire said minimum quantity lubrication is a viable option in addition to dry machining. "Cermets have a higher hot hardness than carbide, so they can withstand higher temperatures."

When running dry, a tool coating can provide an effective thermal barrier while increasing a tool's hardness and reducing wear, said CeramTec's Beck. For ceramic tools, "CVD coatings are the most common coatings, starting from a dual-layer system and going up to a multilayer system. TiC/TiN or Al2O3 layers are the most common."

NTK Cutting Tools' Howard concurred that ceramic inserts are primarily CVD-coated, but the coatings themselves have a limited effect on overall performance.

Beck added that, depending on the application, a PVD coating offers a high wear resistance and high adhesion resistance, which prevents built-up edge and burr formation when machining ductile materials. "Generally, CVD is the best method for coating, which enables higher tool life and increased speeds and feeds."

However, a tool material must have enough conductivity to enable a PVD coating to be deposited on it, Wilshire explained. For example, Al2O3 ceramics are conductive enough, but SiN ceramics are not. "So there we go with the CVD Al2O3 coating."

When possible, many end users opt for a PVD TiN coating because, as the gold-colored coating wears, they can easily identify a used cutting edge, Wilshire said. "It really doesn't improve tool life so much."

Kyocera's cell fiber ceramic grade CF1 has a honeycomb-shaped grain structure in which the hexagon shape that forms the honeycomb is made of tougher ceramic than the harder central core that it surrounds. Image courtesy of Kyocera Precision Tools

To extend tool life, Kyocera offers its PVD Megacoat coating. It is an AlTiN-based coating with a plethora of additives to tailor its properties, according to Wilshire. The dark gray coating also has a nanolayer structure with lubricity between each hard layer to enhance wear resistance and enable higher cutting speeds.

Because ceramics have a low coefficient of friction, getting a coating to adhere can be a challenge, Andersson said. "We had to invent a different method coating, but it's important to understand that you can't take any coating and add it to any cutting tool material—because you can actually make the tool much worse."

Nonetheless, when the coating, substrate, microgeometry, and pre- and post-treatment processes for a ceramic grade are optimized, incredible productivity occurs. According to Andersson, this high level of productivity is even possible when machining metals that aren't usually considered in ceramics' domain. "WG-600 has proven that it can machine 300 and 400 series and PH stainless at speeds that are four to five to 10 times higher than that of carbide."

In addition, it's important that end users understand the best practice for machining with ceramics to achieve the ideal performance of the insert, Howard said. This includes programming ramping cuts, varying the DOC and reducing the feed going into a corner.

For more information about cermet cutting tools from Kyocera Precision Tools, view a video presentation at cteplus.delivr.com/23h4q