Dealing with burn in grinding

Dealing with burn in grinding

The Grinding Doc responds to a shop that is cylindrical-plunge grinding a threadlike shape into tungsten carbide, and is getting grinding burn on the leading face, but not the trailing face.

Dear Doc: I cylindrical-plunge grind a threadlike shape into tungsten carbide. I'm getting grinding burn on the leading face but not the trailing face. Why is this burn only on one face? And how can I get rid of the burn?

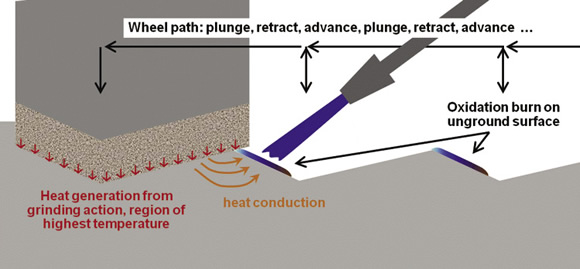

The Doc Replies: This is oxidation burn—brown, yellow and blue marks caused by oxidation of the workpiece at high temperatures. However, you're not getting the burn from the grinding action on that face. You're getting it from heat conduction through the thread onto the previously ground surface.

To get rid of oxidation burn, aim a separate nozzle at the oxidizing surface. This will cool the oxidizing region and starve it of oxygen.

Oxidation burn begins at low temperatures, much lower than the temperatures in the grinding zone. The temperatures on that burned surface were significantly lower than the temperatures on the ground surface during grinding. The wheel was able to grind away any oxidation burn on the ground surface. But on the unground surface, there's no grinding action to remove that thin layer of oxidation burn—so it remains.

To get rid of oxidation burn, add an additional nozzle and aim it at the oxidizing surface. This will cool the oxidizing region and starve it of oxygen.

With this nozzle, the concern is not with applying high-pressure coolant but with aiming the coolant. Two off-the-shelf nozzles you can aim well are from Dr. Cool and SwivelJet. Visit their Web sites at www.cool-grind.com and www.swiveljet.com.

Dear Doc: My wheel supplier includes a 220-mesh dressing stick with each diamond wheel. I'm using a 400-mesh wheel. Is this correct?

The Doc Replies:The grits in the stick should be 20 to 50 percent smaller than the grits in the diamond wheel. Some wheel suppliers have a one-size-fits-all mentality for their sticks. Buy a 120-mesh diamond wheel and what do you get? A 220-mesh stick. That's OK. (Remember, the larger the mesh number, the finer the grit.) Buy a 180-mesh diamond wheel, and you also get a 220-mesh stick, which is good. But buy a 250-mesh, 400-mesh or 600-mesh diamond wheel and you still get a 220-mesh stick. Why they do this, I don't know. But it's wrong. You should ask for a higher-mesh stick or special order one. For a 400-mesh wheel, you want a 600-mesh stick. CTE