Done with one

Done with one

Eliminate applying two countersink tools and a tap to complete a machining operation. A combination tool that countersinks and thread mills.

END USER: A German parts manufacturer.

CHALLENGE: Eliminate applying two countersink tools and a tap to complete a machining operation.

SOLUTION: A combination tool that countersinks and thread mills.

SOLUTION PROVIDERS: Johs. Boss GmbH & Co. KG, + 49-7432-9087-0, www.johs-boss.de; J.M. Sales USA, (248) 321-6170, www.jmsales-usa.com.

A cutting tool dedicated to producing one part feature is all well and good, but one that performs multiple operations is often more cost-effective—even if it's a special. A German supplier to the automotive engineering industry found that to be the case and now needs just one tool instead of the three previously required to manufacture an aluminum crash box, a device that absorbs energy in case of an accident, with a towing hook fixture.

The extruded aluminum profile is supplied to the manufacturer complete with a core hole, which in the previous tooling setup had to be precisely predrilled to produce the threaded hole. Next, the chamfers were countersunk using two tools, and a tap cut the thread.

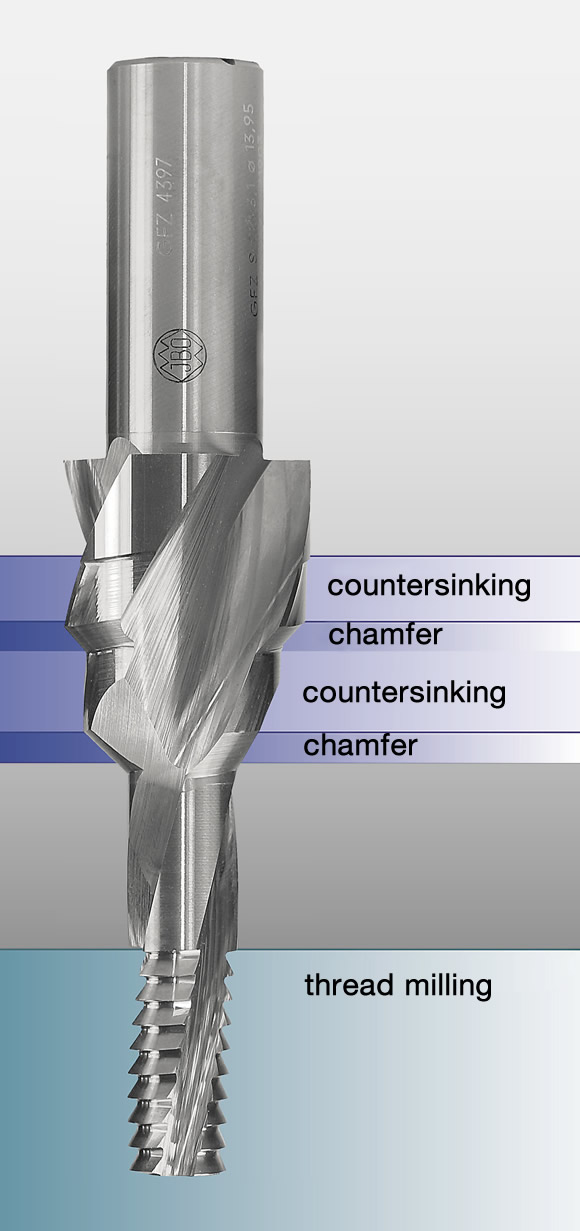

The combination tool performs two countersinking and one thread milling operation in one clamping.

In addition to the drill, three different tools, therefore, were needed to complete the machining operation, which consumed time for changing tools between steps. To optimize this operation, the manufacturer turned to Albstadt, Germany-based Johs. Boss GmbH & Co. KG—JBO for short. (J.M. Sales – USA, Troy, Mich., is the U.S. sales representative.)

Within 3 weeks, JBO had designed, produced and supplied a new solid-carbide combination tool that performs the two countersinking and one threadmaking tasks in a single clamping. The hole still needs to be predrilled, but the accuracy requirements are not as high.

A closer look at the overall machining sequence using the combination tool reveals that countersinking at 1,200 mm/min. produces two chamfers before the tool is withdrawn from the hole to remove chips and then is applied for thread milling at 1,000 mm/min. Spindle speed is 6,000 rpm. The time savings achieved for each part compared with the previous process is 9 seconds. Two parts are produced for each clamping in a double-spindle vertical milling center.

With runs of 2,500 to 3,000 parts per week, this faster cycle time equals an overall time gain of 6.25 to 7.5 hours per run. Assuming an hourly machine rate of about $130.80, this adds up to cost savings of $3,270 to $3,924 per month. In addition, this time gain generates additional capacity for more orders or higher volumes.

Milling rather than tapping a thread generally results in a higher-quality thread surface coupled with better dimensional stability of the thread. This machining method should always be considered, particularly for costly and complex parts, according to JBO. Taken together with the level of process reliability achieved, tangible cost savings can be realized and machining risks averted with thread milling.

JBO added that tapping frequently creates chip-removal problems, such as chip jamming, leading to tap breakage. When that occurs, the tool and workpiece are often consigned to the scrap heap.

Because a thread mill circular interpolates in the hole, chip loading is not a problem. Even a slightly out-of-center offset of the core hole will not cause tool breakage. However, if a thread mill breaks, threading can continue using a new tool. In addition, unlike a tap, a thread mill performs a single, uninterrupted cut, considerably simplifying chip evacuation, according to JBO.

JBO also assisted the manufacturer in programming the vertical milling machine used for the job and supported the shop during introduction of the combination tool, from the trial run through series production that began in October 2012.

Because the first tool is still operating, it is not yet possible to predict its service life. In case of tool wear, the machining program can correct the diameter of the circular movement.

The time savings achieved has improved capacity utilization. Simpler logistical procedures—reduced stock, less time spent in tool management—offer additional cost benefits.