Dust busting innovations

Dust busting innovations

The latest dust collection technology helps keep workers safe and operations efficient.

Maintaining clean and safe work environments is crucial for both worker health and operational efficiency. Advanced dust collection systems are at the forefront of this effort, helping to manage dust and airborne particles that can pose significant risks. This month, we take a closer look at the latest innovations in dust collection technology that are making waves across the industry.

One such advancement comes from Donaldson Company, Inc., a leader in filtration products headquartered in Bloomington, Minnesota. In April, Donaldson introduced the Downflo® Evolution Pre-assembled Small (DFPRE 2) dust collector. This compact and versatile system addresses the growing need for more efficient, reliable and easy-to-install dust collection solutions.

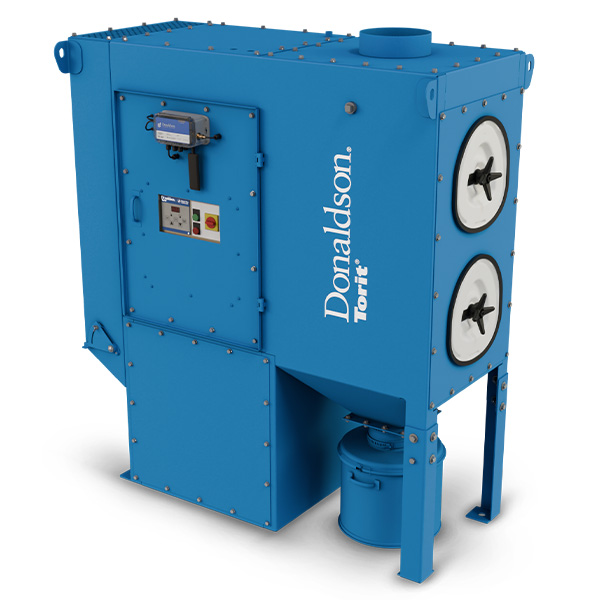

The Downflo® Evolution Pre-assembled Small (DFPRE 2) dust collector offers options for combustible dust mitigation, an integrated spark-reducing inlet and multiple fan motor configurations. Image courtesy of Donaldson Company Inc.

The DFPRE 2 is notable for its ability to handle a variety of dust types and airflow requirements. It offers options for combustible dust mitigation, an integrated spark-reducing inlet and multiple fan motor configurations. These capabilities make it a versatile choice for various industrial applications.

A key feature of the DFPRE 2 is its integration with advanced connected filtration technology. Systems like Donaldson's iCue™ provide real-time performance tracking and analytics, helping facilities maximize uptime, increase maintenance efficiency and ensure compliance with safety regulations. This dust control system is designed to support continuous manufacturing processes, reducing the need for frequent filter replacements and minimizing unplanned downtime.

In addition to Donaldson's offering, another noteworthy product in the industry is the Camfil Gold Series X-Flo (GSX) industrial dust collector from Camfil Air Pollution Control, Jonesboro, Arkansas. The GSX series is designed to handle high-volume dust loads and is known for its modular design, which allows for easy customization and scalability. This system uses Gold Cone™ X-Flo filter cartridges that provide a large filtration area and high efficiency, ensuring effective dust removal. The GSX series is also equipped with advanced safety features, including options for explosion protection, making it a robust solution for industries dealing with combustible dust.

The Camfil Gold Series X-Flo (GSX) industrial dust collector is designed to handle high-volume dust loads and is known for its modular design. Camfil in March introduced the Gold Series Timer (GST), a new dust collection controller. Image courtesy of Camfil Air Pollution Control

Further enhancing Camfil's offerings, the company in March introduced the Gold Series Timer (GST), a new dust collection controller. The GST provides pulse-jet cleaning control, accommodating various solenoid valve types and dust collector sizes. Its integrated differential pressure sensor enables pulse-on-demand cleaning and high-pressure alarms, enhancing safety. The GST features a UV-resistant LCD, front panel controls and expandable input/output options. Diagnostic logic offers real-time alerts for valve and diaphragm failures. An optional GoldLink cellular connection allows cloud-based remote monitoring of key dust collector parameters.

The push for improved dust collection systems is driven by stringent

safety regulations and a growing awareness of the health impacts of industrial dust. Effective dust control not only protects workers but also enhances equipment longevity and reduces fire hazards, making it a critical aspect of modern manufacturing operations.

Recent regulatory changes have driven the adoption of advanced dust collection systems, pushing companies to innovate and adapt. Compliance strategies now include the integration of real-time monitoring systems to ensure adherence to safety standards and improve worker health outcomes.

Globally, regulatory trends continue to shape the industry, with different regions adopting varied approaches to dust control. This global perspective highlights the importance of being well-informed about regulatory changes to maintain compliance and operational efficiency.

By staying on top of these trends and regulatory impacts, manufacturers can better protect their workers, enhance equipment longevity, and ensure a cleaner, safer work environment.

View the safety regulations related to this article at https://www.ctemag.com/node/48541