A few unorthodox machining tips

A few unorthodox machining tips

Shop Operations Columnist James Harvey shares a few unorthodox machining methods that have worked for him.

Tips that shed light on some aspect of machining are tips worth mentioning. Following are some unusual methods of machining that have worked for me.

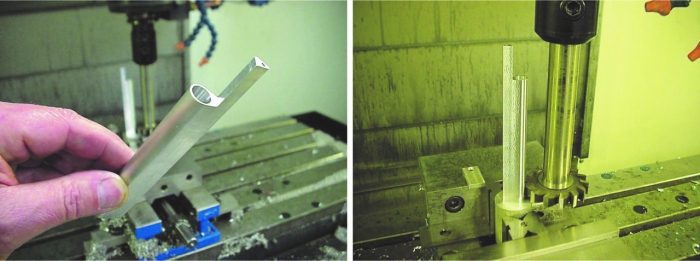

- Experiment with unorthodox cutting routines once in a while. However, these routines won't always work, so be prepared. One day, an order arrived for about a dozen teardrop-shaped parts. I wondered how I was going to hold the parts for machining. After going through various planning scenarios, I came up with an unorthodox plan that would cover the entire job in one setup. Co-workers thought I was crazy. I even thought I was crazy, but the method worked. I chose to stand a bar of aluminum on end and then cut the profile very close to size with a keyway cutter while stepping down the cutter a little at a time. The bar of aluminum provided the rigidity I needed to make the cuts.

An example of a teardrop-shaped part produced with an unusual method of machining. Image courtesy of J. Harvey.

- When engraving, make sure the surface being engraved is flat. Engraving is a task that CNC machines perform splendidly. In one shop where I worked, I had to use a pantograph to do the engraving—what a pain. With CAD/CAM equipment, engraving is a breeze. I like to apply off-the-shelf ballnose endmills for engraving when I can. With relatively large lettering and symbols, ballnose endmills work well. For small lettering, often seen in mold cavities, pointed tools are commonly used. Because engraving cuts are shallow, you must make sure the surface being engraved has been either indicated flat or cut flat (unless engraving a 3D surface). Uneven engraving really stands out, especially when using ballnose cutters. With flat-bottom cutters, you can get away with more unevenness across the surface being engraved.

- A time will come when off-the-shelf cutters won't do the job. To be truly independent, you should learn to make specials, which require craftsmanship and cutter-grinding skills. I've employed the following method as a basis for making many specials: Drill a through-hole the size of the carbide rod near the end of a piece of bar stock. The bar stock will serve as the tool shank. Mill the end of the stock until about 75 percent of the hole remains. Stake the pre-slit carbide in place with a center punch, and silver-solder the assembly. Then grind about 5° relief and clearance into the carbide. These sturdy cutters are suitable as boring bars, undercutting tools and single-flute keyseat cutters.

- Use 3D milling in a pinch to machine large countersunk holes. Because the process is slow, 3D milling is not an ideal method if you have many holes to countersink. However, if you don't have a large enough countersinking tool or you have just a few holes to countersink, the method can be useful. Large countersinking tools cut with a lot of pressure, which can cause material bending, tearing and chatter.

I hope these tips add to your machining knowledge.