Finding the grinding sweet spot

Finding the grinding sweet spot

The sweet spot is where the grits in a grinding wheel optimally penetrate the workpiece to form a chip -- not too deep and not too shallow.

Dear Doc: I keep hearing the phrase "grinding sweet spot." What is it and how do I find it?

The Doc Replies: The sweet spot is where the grits in a grinding wheel optimally penetrate the workpiece to form a chip—not too deep and not too shallow. It's analogous to chip load or chip thickness in milling.

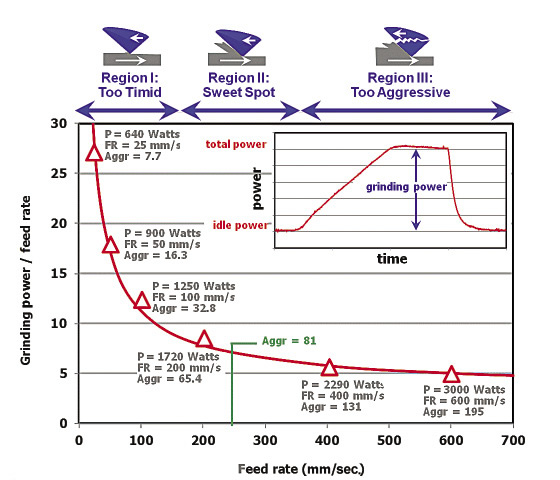

When the grits don't penetrate deep enough to form a chip (see Region I in the figure), they just rub and generate heat. When grit penetration is too deep (Region III), a chip forms but the grits get ripped from the bond material, causing high wheel wear. When the grits penetrate just deep enough to form a chip (Region II), that's the sweet spot.

When grinding parts in large batch sizes, operators are pretty good at tweaking speeds and feeds to find the sweet spot. But what if you want to find it quickly? First, get a power meter, ideally one like my Grindometer that outputs true power in watts or horsepower. An alternative is to use the ammeter or load meter on the machine. That's not as accurate, but will usually get you in the ballpark.

Second, run a few parts at the standard feed rate and measure the power. Remember, you want the grinding power, so you must subtract the power required just to keep the wheel idling. Third, run a few parts at increasingly faster feeds, then at increasingly slower feeds.

Fourth, at each point, note the power in whatever units you want, such as watts, amps or percent of maximum load, and divide it by the feed rate. This is an approximation of the "inefficiency" of the process. Once you have this, plot it against the feed rate. You'll get a curve like the one in the figure.

Once you've found the sweet spot for a combination of wheel, workpiece and machine, you'll want to keep it by calculating the aggressiveness number:

Let's say we find our sweet spot at a feed rate, or workpiece speed, of 15,000 mm/min. Plugging in the other values (DOC is 0.020mm, wheel diameter is 250mm and wheel speed is 27.5 m/sec.) gives an aggressiveness number of 81. This number is used for roughing, when the wheel is doing most of the work. Choose any DOC, feed rate or wheel speed you want, as long as the combination produces an aggressiveness number of 81. When finishing, a smaller value is OK and will help impart a fine surface finish.

My customers have been using this concept for years and enjoying huge benefits. They find that, when roughing, they are always at or near the wheel's sweet spot. They have fewer burn problems (frequently caused by an aggressiveness number that's too low), less wheel wear (frequently caused by an aggressiveness number that's too high) and generally get better results. CTE

About the Author: Dr. Jeffrey Badger is an independent grinding consultant, visiting companies and helping them improve their grinding operations. His Web site is www.TheGrindingDoc.com. He'll be giving his High Intensity Grinding Course in Las Vegas Oct. 20-22 and in Chicago Dec. 3-5, hosted by Greenlee Diamond Tool.