Going deep with holemaking

Going deep with holemaking

The Shop Technology column looks at the significant advances in deep-hole drilling in the October 2014 issue of Cutting Tool Engineering magazine.

Holemaking has significantly advanced in the last 15 years. High-performance drills, when paired with capable machine tools, can eliminate reaming and boring. For example, improved tip geometries provide penetration rates that are almost unbelievable compared to previous standards, and coating improvements significantly extend tool life.

All things considered, however, the most significant advances have been in deep-hole drilling. There is no official definition for deep-hole drilling, but most drill manufacturers consider any hole 15 diameters deep or more to be a "deep hole." The definition also includes making the hole in one pass with no external support for the drill.

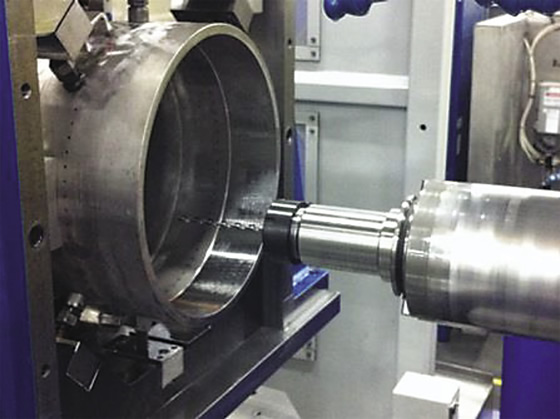

A 6mm (0.236 ") drill produces a hole 20 diameters deep on a horizontal boring mill. Mitsubishi Hitachi Power Systems Americas typically performs deep-hole drilling in the horizontal position to aid chip evacuation.

Uniform nomenclature describes these long drills. Because drill length is specified as a function of the diameter, it is common to see the drill length called out as 15D, 20D and so on. For example, 20D means the drill can produce a hole 20 diameters deep. Therefore, a ½ "-dia., 20D drill can produce a 10 "-deep hole.

Making these holes is a challenge, because long drills tend to "walk," or drift, from the intended direction, resulting in off-center holes. In addition, chips can get packed in the hole, leading to drill breakage, and drilling speeds can be slow.

New drill geometries and drilling techniques can combat most of these problems and allow machinists and engineers to perform operations that might otherwise require a secondary process on a separate piece of equipment. To prevent walking, drills are made to be self-supporting so the flutes fit closely inside the hole. This allows the hole walls to support the drill, similar to a drill bushing. The tools are also ground so that the drill diameter tapers towards the shank. This slight taper ensures only the point end of the drill contacts the part, preventing the drill from binding.

Machine tool advancements have also enhanced deep-hole drilling. Through-spindle coolant is probably the most significant. When making a hole that is 15, 20 or sometimes 50 diameters deep, chip evacuation is the primary concern. Even when drilling shallow holes, it is common to use a peck cycle or withdraw the drill from the hole to expel chips.

The holes in this turbine component are 2.4mm (0.095 ") in diameter and 55mm (2.16 ") deep, about 20 diameters deep. Deep-hole drilling eliminates the need for a secondary process, such as EDMing.

However, withdrawing the drill increases cycle time and may break the drill, so it is beneficial to expel the chips without withdrawing. Through-spindle coolant applied at 300 psi or higher can force chips from a deep hole without pecking or withdrawing the drill. It also ensures there is ample coolant at the point to prevent overheating.

Hydraulic and shrink-fit toolholders have also advanced deep-hole drilling by minimizing drill tip runout. Runout can cause a drill tip to walk off center and generate a hole that is not straight. It can also cause the drill to whip—imagine two girls swinging a jump rope—and break.

It is easy to justify the expense of high-quality toolholders when deep-hole drilling because a broken drill can be costly. Not only does a high-performance drill cost several hundred dollars or more, but a valuable part could be scrapped when a piece of carbide from a broken drill becomes embedded in the part. To prevent that catastrophic event, a monitoring device on the machine tool can sense dull and broken drills and stop the machine.

The primary benefit of deep-hole drilling is minimizing the need for secondary operations. In the past, many deep holes would have required the use of a secondary piece of equipment, such as an EDM. With improvements in drilling technology, it is possible to drill challenging holes on standard machines while performing other machining operations.

Deep-hole drilling also gives design engineers more freedom. Having the ability to efficiently drill deep holes can eliminate the need for multiple components and drive advances in component design that enhance overall component performance.

Several manufacturing engineers and machinists I have worked with were afraid to try deep-hole drilling, preferring to rely on older methods. However, it is a safe and effective process, and an application engineer from a toolmaker can successfully guide users through setup and programming. CTE

About the Author: Christopher Tate is engineering manager, combustion shop, for Mitsubishi Hitachi Power Systems Americas, Savannah (Ga.) Machinery Works, a global builder of gas and steam turbines. He has 20 years of experience in the metalworking industry and holds a Master of Science and Bachelor of Science from Mississippi State University. Email: [email protected].