Grinding with a taper

Grinding with a taper

The Grinding Doc shares a technique that can reduce roughing times from eight hours to 45 minutes with no increased risk of burn

Dear Doc: We cylindrical-traverse-grind long steel parts. We must follow a specification from 1970 that stipulates "traverse maximum one-eighth of the wheel width per workpiece revolution," which is contrary to what you preach regarding using almost the entire wheel width during rough grinding. Is there something we can do? Our cycle times are eight to 12 hours.

The Doc replies: Yes. You can dress a taper into your wheel.

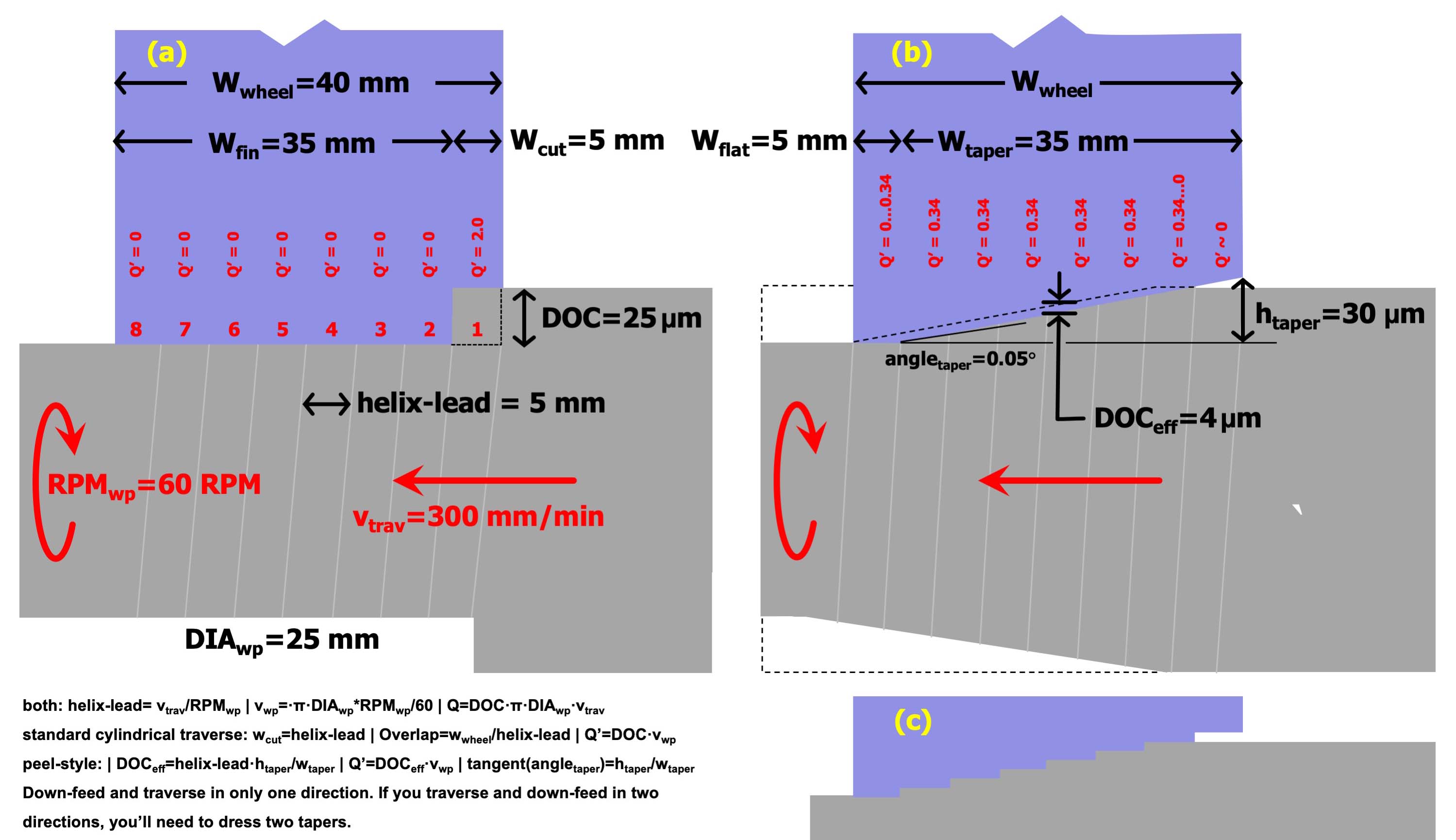

Currently, with your overlap ratio of 8.0, one-eighth of the wheel is doing almost 100% of the work, and seven-eighths of the wheel basically is "sparking out" with a depth of cut close to zero. That's fine for finishing grinding but silly for rough grinding. Use almost the entire wheel. That's why it's there.

But you can't do that. You're stuck using one-eighth of the wheel. So here's what we can do to use almost all the wheel for roughing and still honor that specification: Dress a taper into the wheel.

Dress a flat into one-eighth of the wheel and a taper into the remaining seven-eighths. The taper height should be slightly higher than your DOC — say 120%. This is akin to cylindrical peel grinding.

The formula is tangent(taper-angle) = taper-height/taper-width. In the situation in the figure, that's 0.05 degree.

Dressing a taper in a wheel allows you to use almost the entire wheel for roughing. Image courtesy of J. Badger

That's not much of an angle, but it's enough to shift the grinding action to the taper. It might be tricky to program your machine to dress in such a small angle. If so, you also could dress in a series of steps as shown in (c).

Since now we're distributing the material removal over most of the wheel, we have a smaller effective DOC (DOCeff) — from 25 µm (0.001") to 4 µm (0.00016") in the example. Let's take advantage of that to increase our material removal rate. There are two ways to do it.

The first is to increase both the traverse velocity and the workpiece rpm by a factor of six. I'm not a fan of this method as it maintains the now smaller DOCeff.

If the previous DOC of 25 µm worked, let's stick with it. We do that by increasing the total DOC by a factor of six, to 150 µm (0.0059"). (And raise the taper height to htaper = 180 µm (0.007"), so angletaper = 0.3 degree.)

That 150 µm might seem too deep. But remember, we're distributing it over most of the wheel, so the effective DOC stays at DOCeff = 25 µm. Now we're grinding pretty much as we were before but using 35 mm (1.4") of the wheel width instead of 5 mm (0.2").

But let's not stop there. Since we're rough grinding, let's dress the wheel sharp. Crazy sharp. If we're dressing with a single-point diamond, use a dressing overlap "ratio" of 1.1. If our previous dressing overlap "ratio" was, say, 5.0, the sharper dress will cut our grinding heat generation in half. Therefore, we can double our removal rate. Now let's double both our workpiece rpm and the traverse velocity. With the taper and the sharper wheel, we're removing material at 12 times the prior rate — with no increased risk of burn! Granted, our surface finish is a mess. But we'll fix that during the finish-grind.

Remove almost all the material, dress the wheel flat (and slightly dull), and gently remove the remainder of the material with your 8.0 overlap ratio.

By using this technique, I've had customers reduce roughing times from eight hours to 45 minutes with no increased risk of burn. Finally, don't half-ass or eyeball it. You need to understand the concepts and do it right — or not at all.