IMTS 2016 Preview: Metalworking Products

IMTS 2016 Preview: Metalworking Products

Cutting Tool Engineering provides coverage of more than 210 of the products that exhibitors will showcase at IMTS 2016. They are divided into tooling and workholding products, machine tools and accessories, and metalworking products. Presented here is the preview for Metalworking Products.

Cutting Tool Engineering provides coverage of more than 210 of the products that exhibitors will showcase at IMTS 2016. They are divided into tooling and workholding products, machine tools and accessories, and metalworking products. Presented here is the preview for Metalworking Products.

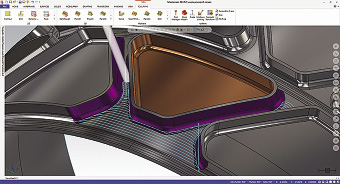

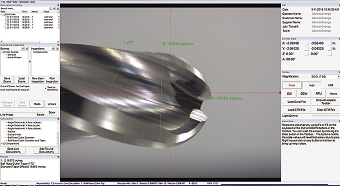

CAM SOFTWARE. CNC Software Inc. says its Mastercam 2017 machining software features a new ribbon interface to make it easier to find the functions users need to complete tasks. The ribbon tabs similar functions and displays them from simple to more complex. Each tab relates to the type of activity, from creating wireframe geometry to generating toolpaths. Editing functions are on the same tab as creation functions to provide access to all the needed tools.

CNC Software Inc.

Booth: E-3340.

VIDEO CAMERA. The Luxxor portable video camera from Gradient Lens Corp. attaches to any Hawkeye rigid or flexible boroscope, as well as most other major boroscope brands. A boroscope can become a videoscope by attaching the boroscope to the video coupler of the Luxxor portable camera. This enables quality-assurance inspectors to quickly identify burrs and other defects inside even complex machined components.

Gradient Lens Corp.

Booth: E-5553.

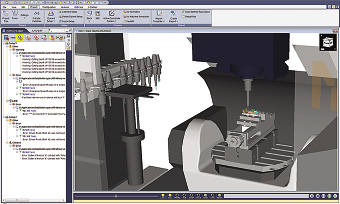

SIMULATION SOFTWARE. CGTech has released Version 8 of its VERICUT CNC machine simulation, verification and optimization software. It simulates all types of CNC machining, including drilling and trimming composites, waterjet cutting, riveting, multitask machining and parallel kinematics. The software operates independently, but can be integrated with leading CAM systems. The Ribbon Bar upgrade allows users to quickly select the function they want to use.

CGTech

Booth: E-3346.

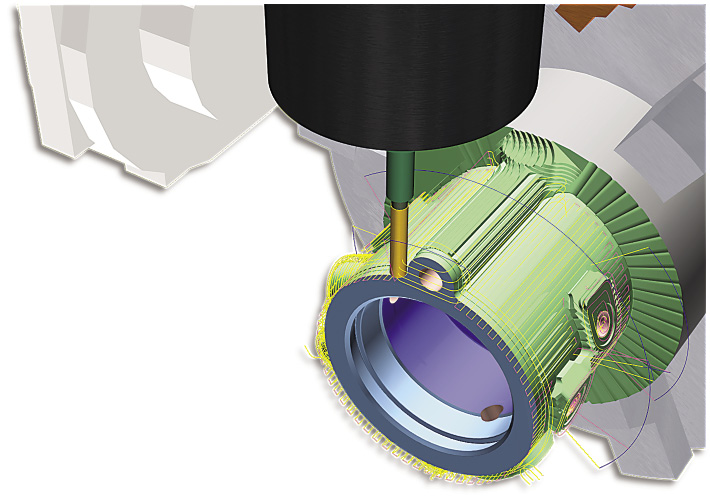

CAM MODULE. SPRING Technologies says its NCSIMUL CAM module streamlines the existing CAM process to simplify CNC programming. It allows users to change, with one click, the target machine without any reprogramming. From the main CAD/CAM program or machine CNC G code, the module generates programs for any machine tool that is verified and optimized without an external post-processor.

SPRING Technologies

Booth: E-3267.

MINIMUM-QUANTITY LUBRICATION. Unist Inc. says its Quantum system gives unprecedented control over MQL applications by digitally setting lubrication amounts to be precisely what is needed. A simple user interface makes setup easy for operators, and active monitoring with alerts lets users make parts with confidence, according to the company. The system is controlled from CNC programs using its RS-232 interface or from discrete inputs.

Unist Inc.

Booth: W-2179.

MAGNETIC SPINDLE ADAPTER. Laser Tools Co. Inc.'s L56SS bar feeder alignment system includes the AP56 magnetic spindle adapter, which provides instantaneous setup for the system's concentric laser beam to shoot through a spindle. The compact adapter is reportedly 95 percent faster than traditional methods, accommodates bores as small as 1⁄16" (1.57mm) in diameter and is portable. Because the adapter works with all collet sizes and chucks, the alignment laser doesn't need to be inserted in the spindle.

Laser Tools Co. Inc.

Booth: N-6344.

MANUFACTURING SOFTWARE. New modules to System Insights' VIMANA predictive analytics platform for manufacturing intelligence include Maintain, for identifying the best strategies for taking preventive maintenance actions , and Sustain, which analyzes energy consumption.

System Insights

Booth: E-4149.

PACKAGING CONTAINERS. Beckett Packaging makes many styles and sizes of telescopic tubes for the cutting tool industry, as well as boxes, cases and containers for standard or specialized packaging. These provide simple solutions to packaging challenges.

Beckett Packaging

Booth: W-2163.

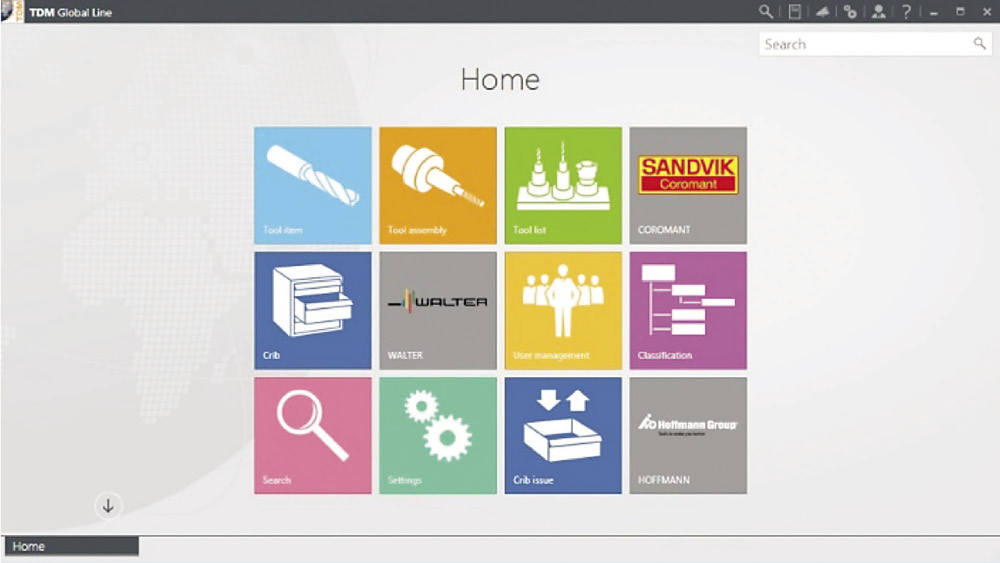

LIFECYCLE MANAGEMENT SOFTWARE. TDM Systems Inc. has released TDMnext, the newest generation of its lifecycle management software. The software is suitable for everything from entry-level activities to global-system integrations. It allows customers to overhaul and update their TDM software without complicated system changes and simplifies interface handling.

TDM Systems

Booth: W-1700

PARTS MARKING SYSTEM. The M4 Inline from Dapra Marking Systems is a turnkey parts marking system built around permanent dot-peen marking technology, It can mark text, logos, data matrix codes, bar codes and serial numbers. The system has a 16-bus card, high-resolution color screen, GUI interface and software. No personal computer is required for operation. According to the company, the system eliminates the need for additional vision identification and control equipment.

Dapra Marking Systems

Booth: N-6256.

I/O BLOCKS. Balluff Inc.'s network I/O Weldblocks are optimized for noisy electrical environments, such as welding applications. They are constructed with fiberglass-reinforced composite (polypropylene sulfide), which inherently resists weld spatter while effectively combatting grounding loops and electromagnetic interference. The blocks are equipped with a built-in enhanced webserver and port diagnostics for quick troubleshooting.

Balluff Inc.

Booth: E-4057.

ULTRASONIC TECHNOLOGY. Acoustech Systems' N-series machining system features a nonrotating module capable of drilling, reaming and tapping, along with options for fixed-pocket machines (Acoustech NFP) and rotating-turret CNC lathes (Acoustech NRT). The ultrasonic technology enables machining of materials that previously were difficult or impossible to machine while reducing waste, coolant and tool wear, according to the company.

Acoustech Systems

Booth: N-6389.

MICROTOOL GAGE. Euro-Tech Corp. says the PG1000-400S-4K gage is ideal for inspecting microtools because it offers 400× magnification, X-micron linear scales and 4K inspection capability. Known as ultrahigh definition, 4K encompasses visual resolution technology that offers four times more pixels than conventional 1,080-pixel high-definition resolution. The gage comes with the company's Reaction software, which enables real-time scale- and edge-detection inspections.

Euro-Tech Corp.

Booth: W-2453.

DOT-PEEN CONTROLLER. Automator America Inc.'s 3.0 release of its AC500 universal dot-peen controller has increased flash memory, extends the list of competitors' marking heads that can be operated by the controller and includes market-requested software enhancements. Programming upgrades allow for deeper marks through multiple dot repetition. The controller weighs 1.46 kg (3.22 lbs.), has a fireproof and dust-resistant resin enclosure, and includes fan vents to enhance air circulation.

Automator America Inc.

Booth: N-6137.

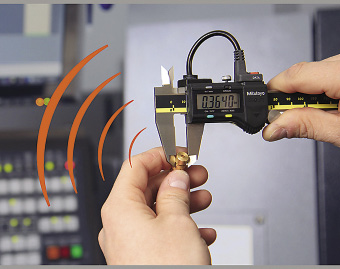

TOOLING ADJUSTMENT SOFTWARE. Caron Engineering Inc.'s AutoComp software enables automatic tool offsetting and calculates the necessary tooling adjustments using any gage to provide dimensional measurements. The gaging devices include coordinate measuring machines, digital tools, vision systems and laser micrometers. The software's PartView makes offset status intuitive, according to the company.

Caron Engineering Inc.

Booth: E-5636.

FLOORING TILES. ErgoDeck tiles from Wearwell Inc. can be installed to cover large areas or custom workstations in environments with foot and light-cart traffic to areas needing drainage or additional traction. According to the company, the product is engineered with the patented LockSafe technology for the evolving workplace.

Wearwell Inc.

Booth: NC-778.

STEEL GUARDING. Faztek LLC's clipless steel guarding virtually eliminates horizontal waviness in wire panels and enhances rigidity. Not only does this create a more aesthetically pleasing product, but, by eliminating obtrusive clips that can snag clothing and loose articles, this steel guarding is safer. Steel guarding can be used to create robotic guards, safety guards, welding cells and conveyor guards.

Faztek LLC

Booth: NC-388.

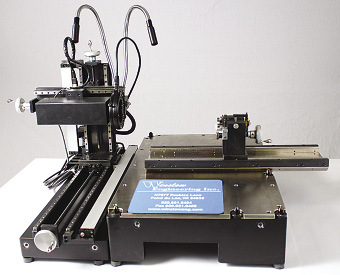

TOOL ANALYZER. Winslow Engineering Inc.'s 560L video analyzer for cutting tools features a motorized zoom-lens assembly. When the operator selects a zoom position in the software, the motorized-zoom lens automatically moves to the appropriate setting without the need for manual lens adjustment.

Winslow Engineering Inc.

Booth: N-7275.

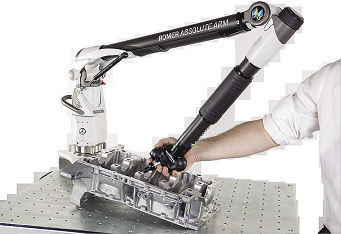

PORTABLE CMM. The 77 series Romer Absolute Arm portable coordinate measuring machine from Hexagon Manufacturing Intelligence is for high-end 3D measurement applications. It achieves nearly a 20 percent improvement in scanning accuracy and a 15 percent improvement in touch-probe measurement accuracy compared to the company's 75 series. The portable CMM is available in five volume-measuring sizes, from 2.5m (8.2') to 4.5m (14.8').

Hexagon Manufacturing Intelligence

Booth: E-5202.

SCREW CONVEYOR SYSTEM. International Surface Technology, or ISTblast, says its screw conveyor system offers a safe and effective surface treatment process while facilitating recycling of popular abrasives, such as glass bead, aluminum oxide, sheet shot and steel grit. Users can achieve recycling rates of 95 percent or more. Recycling reduces abrasive consumption while protecting the environment from harmful sandblasting dust.

International Surface Technology

Booth: NC-141.

WATERPROOF CONNECTORS. Mencom Corp. offers a wide selection of waterproof connectors from IP44 and IP68. The IP (ingress protection) rating is a system for evaluating how "waterproof" a connector is. The first digit represents the protection rating against solid foreign objects, such as dust. The second digit represents the protection rating against liquids. IP65 connectors, for example, provide complete protection against dust and protection of waterjets from all directions.

Mencom Corp.

Booth: E-4152.

MAINTENANCE APP. Smartware Group Inc. launched its first native mobile application for Bigfoot CMMS, the cloud-based assets and equipment management software for maintenance teams. The mobile app provides access to core CMMS functionality using the same login credentials as the browser-based Bigfoot system. Users can quickly navigate parts, work orders and assets through the app's quick-response code or swipe-gesture functionality.

Smartware Group Inc.

Booth: E-5919.

MEASURING SYSTEM. Pinpoint Laser Systems offers the Laser Microgage PRO dual-axis measuring system as a wireless, universal alignment kit. Applications include measuring stage and table runout, aligning bearings and journals, locating gantry rails and cross bridges, checking rail and track parallelism, leveling machinery, measuring shaft and machinery deflections, and providing preventative maintenance information.

Pinpoint Laser Systems

Booth: N-6354.

COORDINATE MEASURING MACHINE. Keyence Corp. says its XM series handheld-probe CMM provides intuitive 3D measurement that is unaffected by variation in measurement points among operators. It requires no previous knowledge of CMM programming. Users select measurement parameters and measure a target to complete programming. Because the images that guide the operator through the measurement positions can also be recorded, work instructions can be completed simultaneously.

Keyence Corp.

Booth: E-5044.

STOCK-HOLDING MAGNETS. Inside/Outside Angle Magnets from Strong Hand Tools hold stock using the inside or outside edges of a workpiece. The magnets hold stock from the outside to leave clearance for inside welds, or hold stock from the inside for outside welds. They are suitable for holding and positioning sheet metal, round pipes and square, angled or flat stock. They are fully enclosed for easy cleaning.

Strong Hand Tools

Booth: W-2088.

LASER MARKING. Schmidt's Class IV laser is for marking large parts that would be impractical to mark with an enclosed laser. The most popular configuration comes with the fiber laser in standard wattages from 10w to 100w. The laser has a 30"×18" (762mm × 457.2mm) baseplate, allowing for easy integration into a range of applications, according to the company. The laser is run with PC-based software.

Schmidt

Booth: N-6159.

COOLANT FILTRATION. Abanaki Corp. offers the Oil Boss coolant filtration system. It uses a specialized collection medium and has a dual-chamber design that allows efficient removal of oil from coolant. The system comes equipped with MagnaCling technology, which allows it to hang from metal surfaces and CNC machines.

Abanaki Corp.

Booth: NC-124.

PVD COATING MACHINE. Kobelco Advanced Coating (America) Inc. says its AIPocket arc-ion-plating PVD coating machine is compact, easy to use and inexpensive. It is suitable for coating inserts, shaft tools, hobs, molds and small parts, such as those for the automotive, aerospace and medical industries.

Kobelco Advanced Coating (America) Inc.

Booth: W-1372.

SERVOMOTORS. Generation II Simotics 1FK7 servomotors from Siemens Industry Inc. are available with seven shaft heights, the Quick-Connect power connector and 20- and 24-bit, field-replaceable encoders in 10 styles. There are three inertia versions: standard, high dynamic for rapid-acceleration jobs and high inertia for maximum smooth running. The motors operate without external cooling.

Siemens Industry Inc.

Booth: E-4502.

BLASTING EQUIPMENT. Comco Inc.'s microabrasive blasters deburr, texture, peen and clean small parts. The equipment applies micron-sized particles of abrasives propelled out of a small nozzle tip at high velocity. It is effective for finishing an array of parts, such as hydraulic valves, gear splines, fuel injectors and medical devices. Manual and semiautomatic units are available.

Comco Inc.

Booth: N-7238.

COORDINATE MEASURING MACHINES. Revolution LM series CMMs from AIMS Metrology have linear motors and Renishaw REVO 5-axis scanning systems. The Revolution HB series shop floor CMMs are 5-axis mobile units. Both models are well-suited to the needs of the automotive, aerospace and medical markets, according to the company.

AIMS Metrology

Booth: E-5836.

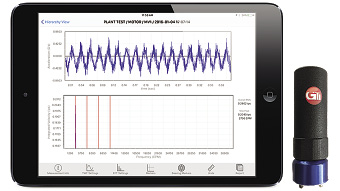

ACCELEROMETER. GTI Predictive offers a Bluetooth accelerometer for iPad tablets. The sensor utilizes instant in-app pairing to make connecting the sensor as fast as possible, according to the company.

GTI Predictive

Booth: N-7433.

INSPECTION SYSTEM. O.C. White Co.'s Super-Scope HD inspection and metrology system provides up to 80× magnification and a choice of working distances, from 6" (152.4mm) to 12" (304.8mm). The system provides onboard image and video capture, calibrated measurement and still vs. live image comparison. A PC is not needed.

O.C. White Co.

Booth: NC-575.

PARTS CLEANER. MiJET's hands-free parts cleaning and collection system uses an existing shop air line and requires no electricity. Stepping on the foot pedal directs air to flow from the fixed nozzle, while also turning on the suction fan to pull coolant into the container. Exhausted air is filtered to levels that can help a facility meet OSHA standards. The system is useful at an inspection station to clean oily parts prior to inspection and improves air quality.

MiJET

Booth: NC-461.

CONVEYOR. The EcoFilter conveyor from Jorgensen Conveyors Inc. features a two-stage chip-removal and coolant-filtration design. Large-chip removal is done with a hinged steel-belt conveyor, and, in a secondary process, fines are separated from the coolant via a wedge-wire filter cell. Brushes wipe the fines from the surface of the cell, where they can then flow to the bottom of the conveyor. Less chip migration to the coolant tank means less tank cleanout and production downtime.

Jorgensen Conveyors Inc.

Booth: NC-542.

GRINDING FLUID. The SintoGrind IG 540 fluid from oelheld U.S. Inc. is for grinding cutting tool flutes, profiles, IDs and ODs. It is suitable for grinding a variety of materials, including tungsten carbide, HSS, PCD, PCBN, cermet and ceramics. It protects against cobalt leaching, is low foaming, helps impart a fine surface finish, offers excellent flushing and cooling properties, has a high flash point and smells pleasant, according to the company.

oelheld U.S. Inc.

Booth: N-7475.

CAM SOFTWARE. 3D Systems Corp. says its GibbsCAM 2016 CAM software delivers increased efficiency, accelerated programming speed, and enhanced visualization and accuracy for CNC machine programming. The enhanced thread milling function includes support for multiple-point tools, tapered threads for single- and multiple-point tools and improved simulation. Added toolpath strategies for 5-axis milling enable users to define toolpath direction using the natural flow of a part surface using the software's Flowline option.

3D Systems Corp.

Booth: S-9119.

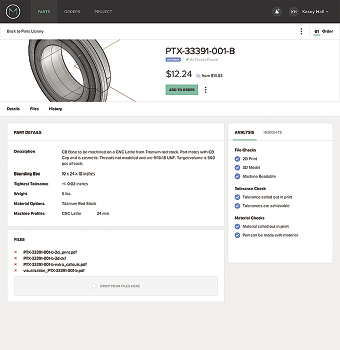

CLOUD-BASED PLATFORM. MakeTime Inc. offers a cloud-based platform that matches a prequalified network of nationwide suppliers with excess machine capacity to companies that need parts. According to the company, the platform streamlines and simplifies the manufacturing process for the entire supply chain, providing local, on-demand manufacturing across the U.S. that's fast, bonded and reliable. This ranges from supplier vetting and RFQs to inspection and delivery.

MakeTime Inc.

Booth: E-3024.

DEBURRING, POLISHING. Bel Air Finishing Supply Inc. offers a line of deburring and polishing equipment for one-piece flow or mass-finishing processes. According to the company, the equipment can work seamlessly with users' existing machinery, processes and manufacturing cultures. Equipment is available for finishing ferrous and nonferrous metals, cast and molded parts, electronic components, delicate parts, and stamped and extruded parts.

Bel Air Finishing Supply Inc.

Booth: N-7567.

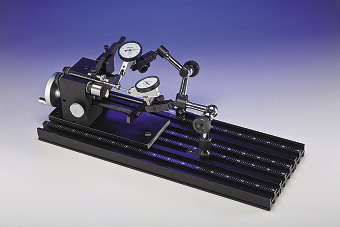

THREAD INSPECTION SYSTEM. The Johnson Gage Co.'s JCR runout and concentricity inspection system is for verification of cylindrical runout. The system can be used by itself or with an optical comparator for verification of cutting tool geometries. It incorporates datum rolls, an upper tension roll assembly, and integral axial stop pins to ensure proper part staging and absolute gage accuracy.

The Johnson Gage Co.

Booth: E-5305.

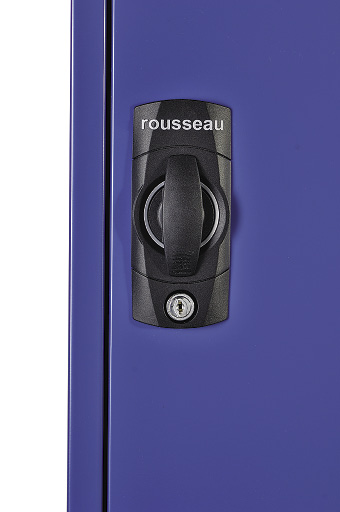

SWING DOORS. Rousseau Metal Inc. offers new swing doors for its "R" line of heavy-duty cabinets and shelving. The doors adjust vertically and horizontally to compensate for uneven floors. The ergonomic handles intuitively turn to the left or right for easy opening. Solid and polycarbonate versions are available.

Rousseau Metal Inc.

Booth: W-2457.

SUMP-PUMP VACUUM. Nilfisk Industrial Vacuums' VHO200 sump-pump vacuum collects metal chips and lubricant and coolant spills, and recycles, separates and discharges gallons of liquids in minutes. Equipped with a diverting valve to reverse the airflow, liquids are quickly pumped out of the tank. Three optional filters are available for higher filtration levels.

Nilfisk Industrial Vacuums

Booth: NC-309.

PROBES, TOOL SETTERS. Marposs Corp. offers Mida diamond touch probes and tool setters. The probes feature piezoelectric technology and are available with various transmission methods, including wired, optical and radio. The tool setters implement a vision technology that uses a video camera to detect tool dimensions, particularly those of microtools, and perform complex measurements.

Marposs Corp.

Booths: E-5516, S-8719.

CAD/CAM PLUG-IN. BobART from BobCAD-CAM Inc. is an artistic CAD/CAM plug-in for Solidworks. Creative tool sets allow Solidworks users to apply artistic elements to CNC-manufactured products, such as signs, jewelry and molds. According to the company, the module enables new revenue-generating activities through expanded product offerings and increased opportunities for upselling.

BobCAD-CAM Inc.

Booths: E-3263, NC-613.

FIBER LASER MARKING. FOBA Laser Marking + Engraving says its Y-Series provides compact, modular and flexible fiber laser marking. The system integrates a range of lasers, optics, a vision system and standard customer interfaces. One laser scan head can handle a range of speeds and quality requirements.

FOBA Laser Marking + Engraving

Booth: N-6038.

PARTS CLEANER. Dürr Ecoclean Inc. offers the EcoCCore solvent-based parts cleaning system, which uses nonhalogenated hydrocarbons or modified alcohols. Switching from one solvent to the other is easy, according to the company. The machine operates under full vacuum conditions and provides heat recovery and full-flow plus bypass filtration capabilities. It comes with two flood tanks.

Dürr Ecoclean Inc.

Booth: NC-276.

SEALING SYSTEMS. The TESS (Thermal Expansion Sealing Systems) from Maier America LLC combines the benefits of a permanently closed seal and the capability to run dry. The system works like a classical closed seal when coolant flows through it. For dry operation, the system detects an increase in temperature and reduces the specific closing pressure applied to the seal faces without separating them.

Maier America LLC

Booth: NC-747.

ULTRAFILTRATION SYSTEM. Sanborn Technologies says its UF 250 ultrafiltration system reduces oily wastewater disposal by up to 98 percent without any chemicals. The advanced membrane technology provides cost-effective waste reduction of spent coolants, floor washings, aqueous parts washer discharges and vibratory finishing effluents.

Sanborn Technologies

Booth: N-7538.

SUMP CLEANER. CECOR has introduced the SE15-60PL single-phase, 60-gal. (227 L) Sump Shark sump cleaner. With a suction lift of 13" HG or 177" water and pumping rate of 60 gpm, the cleaner can suck an entire sump of metalworking fluid entrained with sludge or chip in minutes, according to the company. As contents enter the unit, an onboard filter separates fluid from the solids. It has overfill protection and all discharge ports are valved.

CECOR

Booth: NC-363.

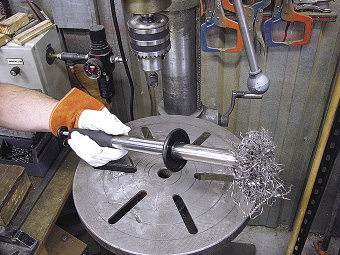

CHIP PROCESSOR. PRAB Inc.'s E-Series chip processing system reduces volumes of metal turnings into thumbnail-size chips, separates oil and dry chips, and collects oil for reuse. According to the company, it engineers and manufacturers the equipment based upon the exact needs and specifications of the application. This enables end users to be assured the equipment will work in the application for which it was designed and deliver long-term, reliable service.

PRAB Inc.

Booth: NC-238.

![]()

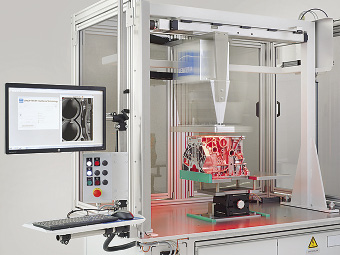

MEASUREMENT SYSTEM. InfiniteFocus from Alicona Corp. is an optical 3D surface measurement system. With the Automation Manager interface, end users can perform measurements automatically. This enables the use of the measurement system in production environments by operators without any measurement know-how, according to the company. The measurement results are directly relayed to a production control system.

Alicona Corp.

Booth: E-5833.

OPTICAL SURFACE INSPECTION. The IPS 400 from Jenoptik Automotive North America is for rapid optical surface inspection of flat, machined surfaces. The system provides a map of critical surfaces of parts, such as crank cases, cylinder heads and valve bodies, where surface condition is essential to effective sealing and economical functioning. The system detects common surface defects, including burrs, pores, hit marks and scratches. The inspection area is 400mm wide × 800mm long (15.75"×31.50").

Jenoptik Automotive North America

Booth: E-5536.

MONITORING SYSTEM. FactoryWiz Monitoring from Refresh Your Memory Inc. collects live, unbiased shop floor data to create baseline metrics and identify process-improvement opportunities. The system reportedly enables the status of, and reports for, CNC machinery and other production equipment to be available 24/7 on large display monitors in common work areas, desktop monitors and mobile devices from any web-enabled product anywhere in the world. It is MTConnect-compliant.

Refresh Your Memory Inc.

Booth: E-3363.

FILTRATION SYSTEM. Transor Filter says its V-Series filtration system combines the convenience of the company's centralized unit with the expandability of smaller, modular models. The system has a filter module that consists of three filter vessels, a filter pump and the required plumbing. Each filter module supports three machine tools. A base unit can initially be configured to accommodate future growth.

Transor Filter

Booth: N-7440.

SLUDGE RECYCLING. Tungco Powder Procurement specializes in recycling tungsten-carbide sludge, also known as swarf or soft scrap. The company says it provides a prompt, accurate analysis of the material and buys wet or dry sludge with tungsten content from 20 to 90 percent. The company purchases from domestic and international sources and assists with any logistics.

Tungco Powder Procurement

Booth: W-2192.

PARTS CLEANING. An Ultrasonics parts cleaning system from Miraclean Aqueous Cleaning Systems can be designed for cleaning, penetrant inspection or citric and/or nitric passivation. The automated system has a small footprint. The company provides technical information about setting up a citric passivation line and citric passivation equipment and chemistry.

Miraclean Aqueous Cleaning Systems

Booth: NC-339.

PARTS CLEANING SYSTEM. Crest Ultrasonics' Solvac S-1 solvent cleaning system is based on immersion/vapor-phase cleaning technology using nonflammable, halogenated solvents. To effectively clean parts with minimal solvent usage, the system has a "sealed lid" design and employs "Vaportronic" electronically controlled pulse heating. It is suitable for cleaning ferrous, nonferrous and sintered materials.

Crest Ultrasonics

Booth: NC-245.

MAGNETIC BATONS. Master Magnetics says its Magnetic Retrieving Batons effectively remove machining-generated, wet and dry fine metallic filings, turnings, swarf and shavings. They are constructed with neodymium magnets to maximize holding power, have a noncorrosive stainless steel housing and are available in four styles.

Master Magnetics

Booth: W-2280.

TRAMP OIL SEPARATOR. The mobile centrifuge from Eriez provides high-speed centrifugation. It recycles fluids at the machine sump by placing suction and return hoses directly in the sump, removing free and emulsified oils from water-miscible coolants and aqueous cleaners. The unit automatically shuts off when the tramp oil collection tank is full.

Eriez

Booth: N-6966.

TOOL MEASUREMENT. Zoller Inc.'s compact roboSet 2 smart automation solution for tool measurement can be coupled with the company's Genius or Titan universal measuring machines, and it can be supplied with laser or ultrasound-cleaning capabilities. It has a multiple-pallet system for unmanned QA and production processes.

Zoller Inc.

Booth: W-2022.

MEASUREMENT SYSTEM. Mahr Federal Inc.'s MarShaft SCOPE 600 plus 3D provides 3D functionality and workpiece inspection in a single measurement. The matrix camera optically measures characteristics such as diameter, length, radius and shape. A 2D sensor detects features that are not optically measurable, such as cam lift on a concave cam profile and reference, or clocking, features, such as holes and keyways.

Mahr Federal Inc.

Booth: E-5614.