Innovative ways to grip the ungraspable

Innovative ways to grip the ungraspable

Workholding: Suppliers develop solutions for parts that are simply hard to hang on to.

Among vises, collets and chucks, there's no shortage of reliable methods to secure workpieces for machining. Still, some parts are simply hard to hang on to. Clamping too aggressively on thin walls and delicate geometries causes warpage and accuracy problems and may lead to scrap. Fortunately, a number of workholding suppliers have developed innovative ways to grip the ungraspable.

IBAG North America, North Haven, Connecticut, is one. President Bill Popoli said using a Witte Ice-Vice Freeze Chuck can be an effective way to clamp thin, flat parts when other methods fail. "We offer two types. The first works much like an ice hockey rink, where coolant is circulated through a flat chuck and back to a refrigeration system. You spray the face with a little water mist, set the parts on and energize the system."

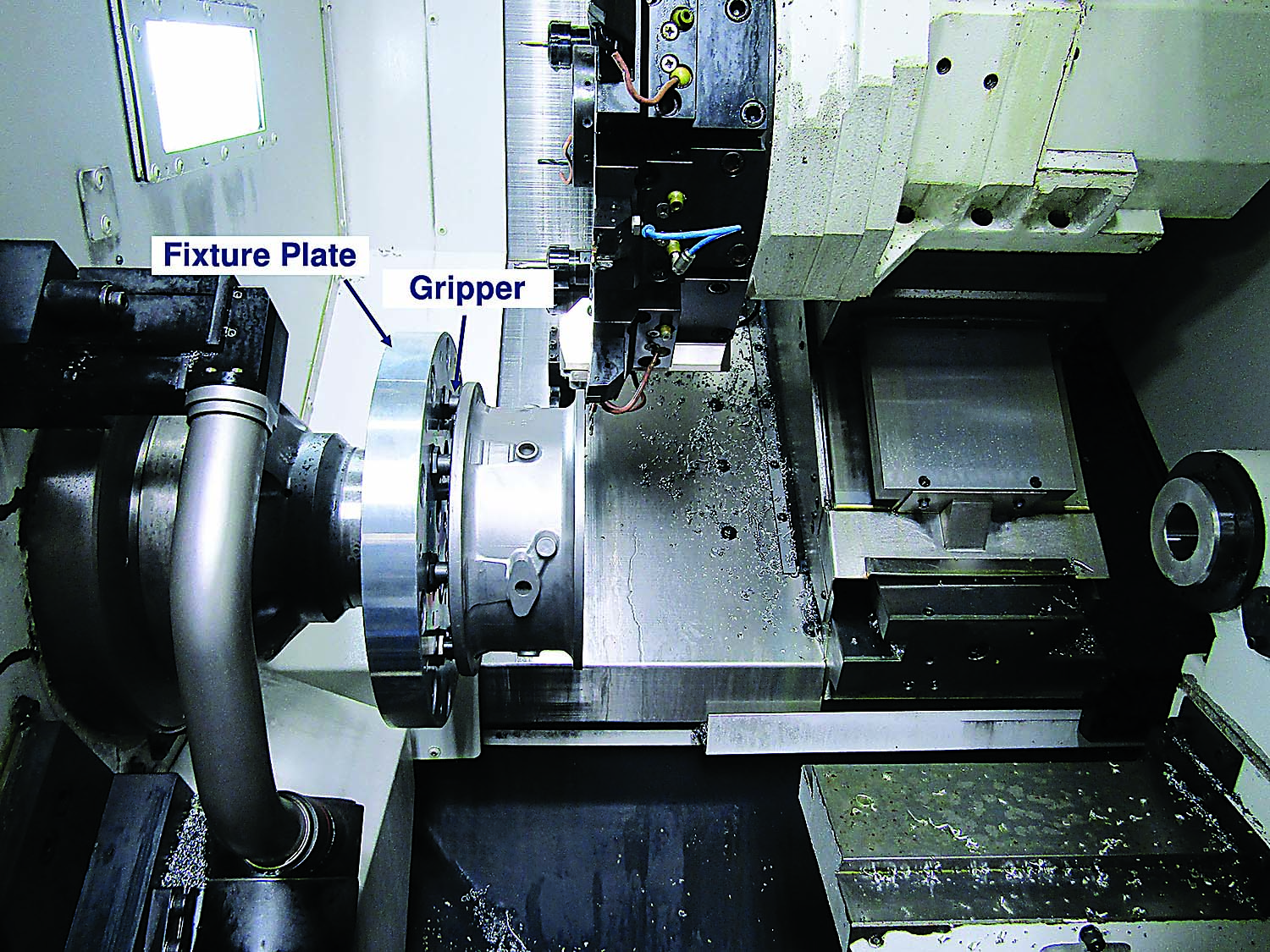

Blue Photon's photo-curable adhesive and patented gripper system is strong enough for a variety of machining applications. Image courtesy of Blue Photon Technology and Workholding Systems

Freezing takes around a minute, he said, depending on the size and quantity of the parts. Yet the custom-made system is admittedly expensive. A lower-cost alternative is an icing chuck that uses the Peltier effect. It works by applying electrical current to an internal thermocouple device, rapidly cooling the device and the surrounding area. Chucks with a 250mm × 150mm working area are available. There's also a system that uses compressed air and the Venturi effect to rapidly cool the chuck surface.

With an accuracy of ±3μm and holding power up to 150 N/cm², ice chucks are surprisingly robust but create no external forces that may cause workpiece distortion. It's possible to cut pockets in the surface of the chuck, making it easy to position parts, Popoli noted.

"We also offer an alloy that can be used to encapsulate parts prior to machining," he said. "It's a white metal with a melting point of around 170º F. You set the part in a potting fixture or premachined cavity, pour the melted alloy around it and machine as usual. It's a good, low-cost solution for low-volume production of thin-walled or irregularly shaped workpieces."

A similar solution can be found at MachinableWax.com Inc., Traverse City, Michigan. Technical Manager Wes Elias said Rigidax tooling compound is a pour-on thermoplastic with a cured hardness of 40 to 50 Shore D, which is "about as hard as the tread on a truck tire" and available in various formulas for different applications.

"Sometimes you want a lower-viscosity wax to reach into smaller channels where other applications may require higher adhesion that comes with the thicker-viscosity formulas," he said. "The more common green formulas contain ground fiberglass to help reduce shrink and increase compressive strength. We also offer formulas that omit this fiberglass for applications like optics or extremely fine finishes where it may cause scratches on the material the wax is holding. Applications where no cutting fluids are used can benefit from a water-soluble version, which makes cleanup very easy."

Elias recommends heating the workpiece when possible to improve wetting, then pouring the melted wax around the workpiece to secure it. Most formulas have a pour temperature up to 275º F, although a water-soluble version pours at 200º F. After machining, the process is reversed. The wax can be used multiple times. A small amount of residue should be expected but is easily removed with a heated mineral oil bath or special wax remover.

"If you have an oddly shaped part or a thin-walled part that would otherwise be difficult or impossible to hang on to, wax is a great way to capture it," he said. "We also find that it helps reduce vibration during machining, improving part accuracy and tool life."

Blue Photon Technology and Workholding Systems LLC, Shelby, Michigan, has yet a different approach. A strong photo-curable adhesive in conjunction with patented grippers offers a way to hold complex-shaped parts that are not flat. President and CEO Dan Billings said photoactivated adhesive workholding is an increasingly popular method to grip delicate and/or hard-to-hold parts. The gel-like adhesive fills the gap between the part and the gripper, allowing for variation in parts. Three gripper sizes are available that permit holding forces of 200 to 600 lbs.

The Blue Photon system can be combined with zero-point systems and a bond station to make a "datum transfer" tool, providing a way to easily load complex-shaped parts. When done machining, a socket wrench is used to shear the bond between the gripper and part or the transfer tool can be soaked in hot water for 1 to 3 minutes to remove the part. The system is suitable for ferrous and nonferrous materials, ceramics and plastics and is resistant to cutting fluids.