Inspecting with light

Inspecting with light

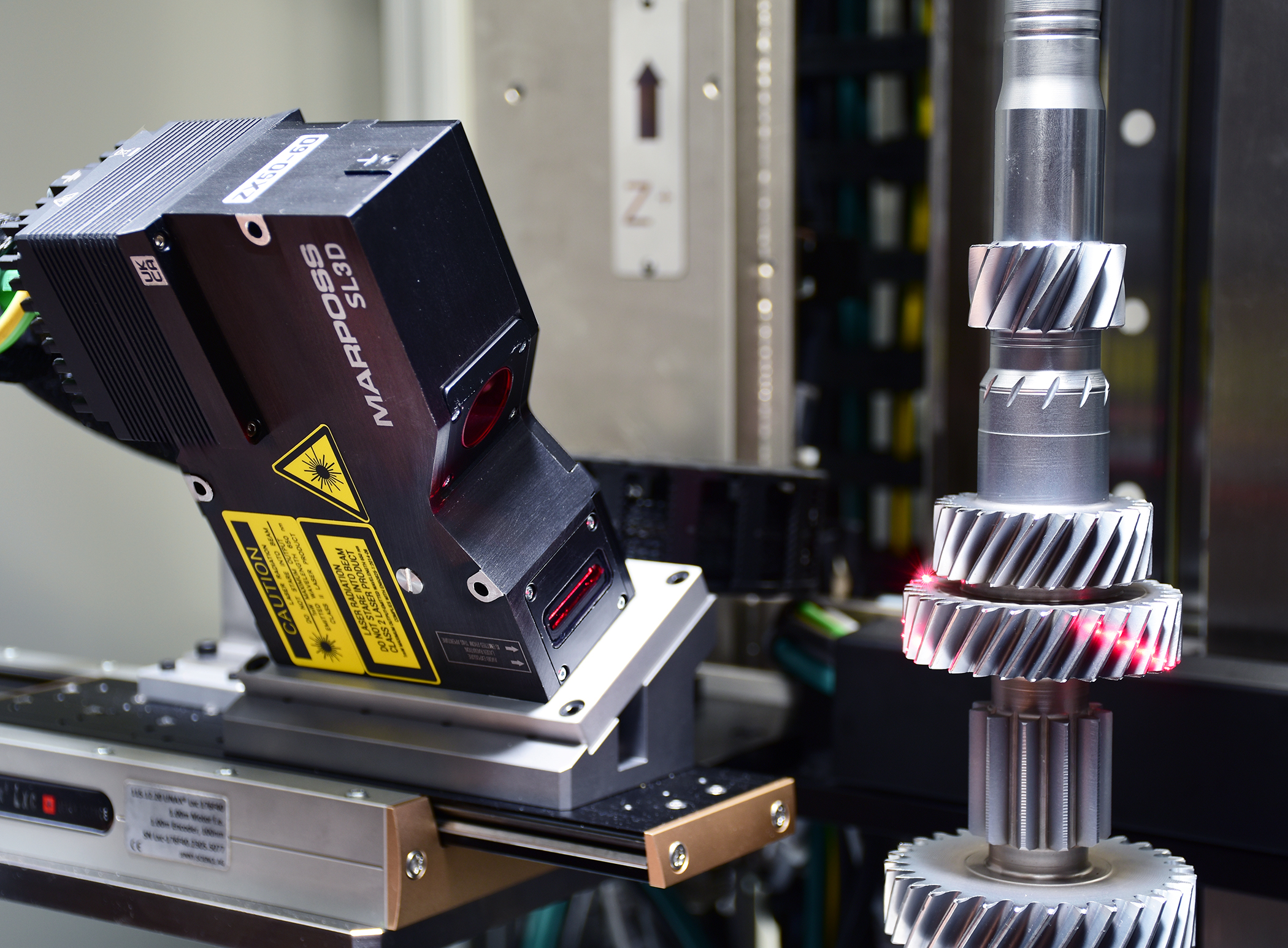

The Marposs OptoCloud Gear helps EV manufacturers maintain quality and minimize noise.

A new addition to a line of optical inspection systems is designed to help get electric vehicles in gear.

The system, called OptoCloud Gear, is the latest EV-focused OptoCloud product rolled out by Italy-headquartered Marposs S.p.A. Marposs developed OptoCloud Gear to help manufacturers maintain high gear quality and minimize gear-meshing noise, both of which are top priorities in the EV industry. The system does this by precisely measuring gear features such as the profile and helix angle, as well as gear micro geometry, the company notes.

A major advantage of OptoCloud Gear cited by Marposs is the system's ability to take non-contact measurements across multiple sections and positions. Key to this is the company's SL3D triangulation laser, which is capable of acquiring up to 1,000 component profiles per second in order to ensure precise part reconstruction while also minimizing measurement time.

OptoCloud Gear is designed for noncontact gear inspection in the electric vehicle industry. Image courtesy of Marposs">

OptoCloud Gear is designed for noncontact gear inspection in the electric vehicle industry. Image courtesy of Marposs">"If you have to do contact measurements of complex shapes like gears, you will require a lot of time to take enough point measurements to reconstruct the shape of the object," noted Nicola Pasquali, the company's product manager for optical gauging systems. "With our technology, you have a complete 3D reconstruction of complex shapes in (just) a few seconds."

While conventional contact measurement of a gear could take several minutes, the same task will only take about 30 seconds using OptoCloud Gear, Pasquali estimates.

According to Marposs, the 3D reconstruction provided by OptoCloud Gear is a clear and comprehensive visual representation that makes it easy for operators to understand inspection data at a glance. Though the high-density point cloud currently shows only gear dimensions, Marposs plans future enhancements that will also reveal key part characteristics such as porosity, cracks, chips and scratches. This gear information can help EV manufacturers prevent problems in end-of-line noise, vibration and harshness tests, as well as eliminate the need for costly repair and disassembly of noisy transmissions.

OptoCloud Gear's optical inspection capabilities can be supplemented by the integration of conventional sensors. These allow measurement of features such as bores and undercuts that cannot be reached by light from the system's laser.

Allowing both manual and automatic operation, OptoCloud Gear can do its work in a dedicated room or close to production lines. Though other inspection options on the market offer 3D laser scanning, the short cycle time of the Marposs system makes it a good fit for inline use and thereby sets it apart from the competition, according to Pasquali. He also pointed out that OptoCloud Gear requires almost no manual retooling for product changeovers, making it suitable for high-mix, low-volume production environments.

Reduction or elimination of human involvement is one of the main selling points of inspection systems like OptoCloud Gear. Compared to manual inspection of EV gears, Pasquali noted that OptoCloud Gear does more than just save time. "This product will keep production quality constant," he said. "When you have a complex item, it's difficult for the human eye to be consistent with inspection. But for an automatic machine, it isn't."