Look Ahead: A grinding machine designed for sintered ceramics

Look Ahead: A grinding machine designed for sintered ceramics

Most manufacturers finish their sintered ceramic parts with grinding equipment designed for metals. Tratech Corp., however, has introduced what it says is the first commercially available CNC grinding machine designed specifically for the demanding needs of machining fully sintered ceramics.

An increasing number of parts for multiple industries are being made of strong, heat-resistant, lightweight ceramics. This increase is because the craft of sintering ceramic materials has improved in recent years, allowing parts of appropriate density to be made more cheaply and easily than ever.

Most manufacturers finish their sintered ceramic parts with grinding equipment designed for metals. Tratech Corp., however, has introduced what it says is the first commercially available CNC grinding machine designed specifically for the demanding needs of machining fully sintered ceramics.

Tratech says its Advanced Grinding System (AGS) features an ultrahigh accuracy, 42,000-rpm, through-coolant spindle capable of material-removal rates of 0.06 in.3/min. (1.52 mm3/min.).

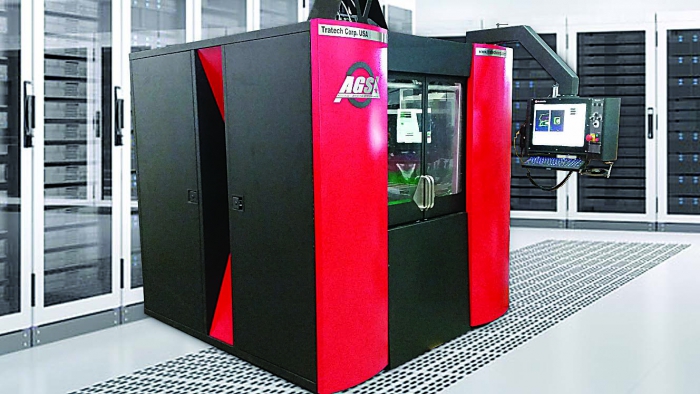

The AGS 3-axis CNC machine is designed for grinding fully sintered ceramic parts. Image courtesy of Tratech.

The machine has a 500mm (19.68") × 500mm × 500mm work envelope. A stationary machine bed utilizes an XYZ gantry design to protect the motion control components from abrasive ceramic particles. The bed and motion components are isolated from the machine frame to mitigate environmental impacts on the machining process.

The AGS also features several patent-pending technologies, such as an intelligent process-force-detection system, which automatically stops the grinding process and lifts the wheel out of the workpiece when overload and wheel-failure conditions are detected. In addition, a 16-tool toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: toolchanger/" data-glossary-id="142091" data-glossary-teaser="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" title="Mechanism typically included in a machining center that, on the appropriate command, removes one cutting tool from the spindle nose and replaces it with another. The changer restor…" aria-label="Glossary: automatic toolchanger">automatic toolchanger">automatic toolchanger features an on-the-fly tool tray system that keeps 256 tools in process storage. Tools and trays can easily be swapped and loaded without interrupting the machining process.

The AGS is capable of grinding very delicate parts that would be unthinkable to grind with any conventional machining process, said Tratech's head of business development and marketing, Nicole Travert. She said the AGS can produce a 1mm-wide (0.039") wall with a 1:10 width-to-height ratio without any microfractures or surface damage, "leaving a perfectly sharp edge."

For more information about Tratech Corp., Fort Lauderdale, Fla., visit www.tratechcorp.com or call (844) 408-9252.