Look Ahead: Titanic robot, tiny tolerances

Look Ahead: Titanic robot, tiny tolerances

An item in the Look Ahead department of the August 2017 issue of Cutting Tool Engineering magazine features large-volume, high-accuracy robots.

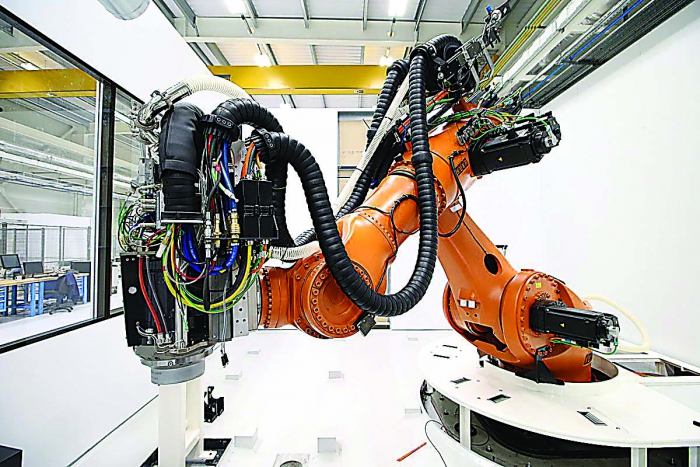

In 2007, the KUKA Titan entered the Guinness World Records as the world's largest and strongest robot. A decade later, a modified version of the behemoth has accuracy unprecedented for its size—better than 100µm (0.0039").

This customized device was developed to give the U.K. aerospace sector a unique capability for high-accuracy robotic machining.

The University of Sheffield's Advanced Manufacturing Research Centre (AMRC) launched the Flexible Robotic Machining in High Accuracy Applications project with Boeing Co. The project had backing from the U.K.'s Aerospace Technology Initiative (ATI) to develop an accurate robotic milling system.

The goal was to "create the most accurate large-volume machining robot in the world," said Ben Morgan, head of AMRC's Integrated Manufacturing Group at its Factory 2050 collaborative-research facility.

The modified KUKA Titan at AMRC's Factory 2050. Image courtesy of AMRC.

AMRC started with a KUKA Titan that could carry a payload of more than 750kg (1,653 lbs.), with a reach of over 3.2m (10.5'). The team replaced the encoders that let the robot know where it was in space with highly accurate Renishaw rotary encoders, linking them to its Siemens 840D controller.

Morgan explained that the new encoders are closer to the end effectors—where the action is. "This improvement means the new encoders have higher resolution and negate any gearbox backlash inaccuracies."

The approach was developed by aerospace automation specialist Electroimpact Inc., Mukilteo, Wash., which has experience creating accurate robots and has sold systems for drilling in aerospace applications.

After 3 years of robot-machining research for aerospace OEMs and high-end automotive manufacturers, AMRC identified the need for the project. It has the potential to develop accurate and stiff robotic-machining capabilities for both metallic and composite structures, offering manufacturers increased flexibility and efficiency when it comes to producing higher-quality components, according to Morgan.

The modified Titan could lead a new generation of high-volume, high-accuracy robotic machining, reducing the need for expensive, specialized multiple-axis machine tools in aerospace and other industries.

"There is great potential to achieve a step change in high-accuracy robotic machining on the back of our previous research and our understanding of the fundamental mechanics," Morgan said.

For more information about the University of Sheffield's Advanced Manufacturing Research Centre, Sheffield, U.K., visit www.amrc.co.uk or call +44 114 215 8200.