Machine Shop Innovation

Machine Shop Innovation

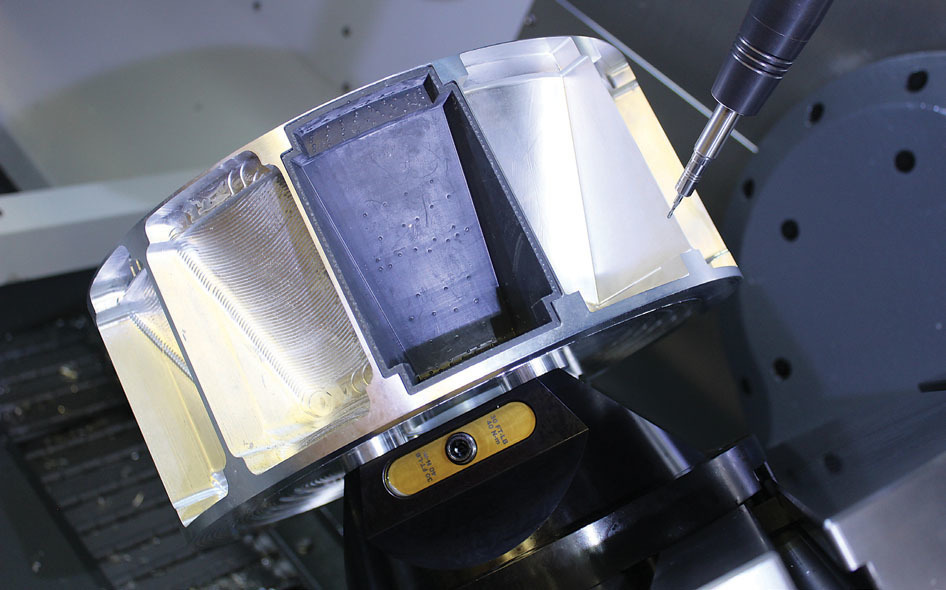

NASA Glenn engineers created 3D-printed vibration-damping inserts that boost machining accuracy, cut cleanup time and improve prototype manufacturing efficiency.

ASA's Glenn Research Center in Cleveland, Ohio, designs, develops and tests innovative technology to transform aviation, revolutionize space exploration and inspire new discoveries for the benefit of all. Every U.S. aircraft has NASA Glenn technology on board, making flight safer, quieter and more efficient. Every day, engineers at Glenn are conducting revolutionary aeronautics research in electrified aircraft propulsion, advanced materials and exploring next-generation supersonic and hypersonic aircraft.

Ingenuity and problem-solving are part of the culture at NASA Glenn for every employee in every job at the center, and engineering technicians Christina Rapenchuk and Jonathan Veneziano, who work in Glenn's full-service machine shop, are no exception. In the process of manufacturing prototypes, the pair decided they needed a new way to reduce vibration during machining, and that led them to an innovative and better way to machine complex shapes by using 3D printing technology. Rapenchuk and Veneziano named their solution the Specialized Vibration Mitigation System (SVMS).

The shop's role at NASA

The NASA Glenn Machine Shop provides the aerospace research center with a variety of manufacturing capabilities. It runs primarily as a prototype shop, creating one-offs or small quantities of parts for supporting researchers and helping them to develop their ground test articles, flight articles and prototypes for testing in the various test facilities at the center. The machine shop also creates hardware for some of those facilities, like the aircraft icing research tunnel, supersonic wind tunnels and the zero-g drop tower.

The full-service machine shop features three-, four- and five-axis CNC milling machines, CNC lathes with live tooling, surface and cylindrical grinders, as well as wire and die sinker electrical discharge machines (EDMs).

Part of the facility is dedicated to additive manufacturing and equipped with an array of 3D printing technology, including a wide range of engineering photopolymers, plastic fused deposition modeling printers, and stereolithography apparatus printers — a type of resin 3D printer that uses a laser to cure liquid photopolymer resin layer by layer. The additive manufacturing shop is also equipped with a metal printer, which can print 17-4 PH stainless steel, copper and Inconel 625 nickel chromium.

In addition, the shop is capable of micromachining lenses, mirrors and other hardware that require high-precision, high-accuracy and/ or high-surface finishes.

The challenge of vibration

When machining thin-walled features on parts, the lack of rigidity introduces vibration into the system. Vibration, in combination with cutting forces causes chatter, which can lead to poor surface quality and out-of-tolerance features, as well as being detrimental to tool life.

The use of clay as a stabilizer is the traditional way to combat vibration and chatter while machining parts. Clay is dense and sturdy enough to add support to thinwalled features and can withstand cutting conditions and fluids. However, clay is a dirty material that can be hard to clean from parts and is time-consuming to implement.

NASA engineers don't always have extra time. Their testing plans are part of project builds or readiness demonstrations, and facilities are scheduled well in advance for testing. The machine shop is tasked with manufacturing prototypes for testing accurately, quickly, efficiently and economically.

The 3D-printed solution

SVMS dampening inserts are custom-designed and 3D-printed for use with a specific workpiece to be machined. SVMS dampening inserts are composed of a rubber resin that is flexible without loss of integrity. These inserts can be stored and reused for identical projects, and they can last for up to two years before breaking down, depending on frequency of use. The customized, 3D-printed inserts enable a machinist to create any complex shape that needs support during cutting, milling, boring, turning or grinding.

Use of SVMS instead of the traditional clay method reduces the vibration in almost all areas. In some cases, the traditional clay method can still be used in conjunction with SVMS to eliminate the vibration, hold tolerance and keep the feature more dimensionally accurate.

This system can be implemented in any machine shop. Using additive manufacturing methods to 3D print custom-sized dampening inserts allows machinists to perform high-tolerance milling, boring, turning and grinding. SVMS is currently being used for prototype manufacturing, providing an efficient method for manufacturing prototypes with complex parts and high-tolerance specifications.

In the manufacturing field, complex shapes can be made to fit features that would otherwise be too time consuming or difficult to achieve using traditional methods. Any manufacturing industry utilizing soft and hard metals, plastics and composites could potentially apply and benefit from this process. Aerospace, automotive and appliance parts manufacturers are just a few examples.

This innovation allows for 100% customization that allows the NASA machine shop to meet the specifications of a specific machining task. Using the SVMS process, hardware can be machined more efficiently with a shorter set-up time and easy mobility, allowing for a quick change of setups.

Rapenchuk and Veneziano have been using the SVMS system successfully in Glenn's machine shop since 2021, primarily for the manufacture of prototypes, and it has resulted in cleaner, easier and faster machining of parts. Also, the risk of damage to parts caused by vibration is mitigated, saving labor and machining time.

Compared to traditional clay vibration stabilization, using the SVMS 3D-printed dampening inserts has saved an average of one to two hours in clean-up time per job, and up to 12 hours on more complex jobs. The time savings is primarily with clean up — because clay gets messy.