Manufacturing gear for choppers

Manufacturing gear for choppers

Apply modern manufacturing methods to grow a custom motorcycle business. Automate production and improve part quality and machining efficiency with a CNC machine tool and CAM software.

END USER: Box39, +7 (921) 941-85-61, www.box39.ru.

CHALLENGE: Apply modern manufacturing methods to grow a custom motorcycle business.

SOLUTION: Automate production and improve part quality and machining efficiency with a CNC machine tool and CAM software.

SOLUTION PROVIDERS: Haas Automation Inc., (800) 331-6746, www.haascnc.com; DP Technology Corp., (800) 627-8479, www.dptechnology.com.

Vladislav Belyakov had long been driven by the idea of putting together a custom motorcycle in Russia. He soon discovered the necessary components must be imported, driving up costs and delivery time. Also, there were few local companies that had the CNC machines needed to produce high-quality custom components at a reasonable price.

"In most cases, these companies had to perform time-consuming and expensive manual finishing operations," Belyakov said. "They were unable to produce complex parts with irregular shapes, such as multiple undercuts, surface openings and transitions in different planes."

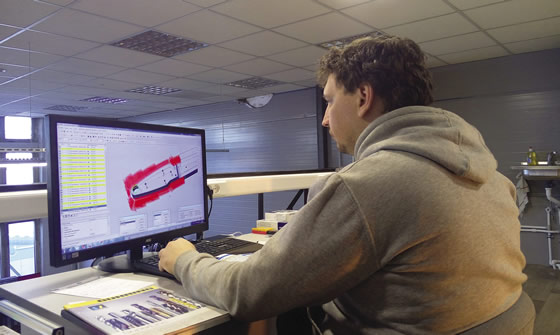

Box39 uses ESPRIT CAM software from DP Technology to program a Haas 5-axis machine. Image courtesy Box39.

Belyakov saw the manufacturing deficiencies in Russia as an opportunity to start a new business venture. He jumped from a career in financial services to motorcycle parts manufacturing in 2011 and launched Box39, a custom motorcycle shop in St. Petersburg. "Our first production facility was a rental garage," he said. "We designed and put our first product out within 6 months of opening the doors."

The company invested in CNC equipment to improve the quality and production efficiency of its existing products, according to Belyakov. Additionally, the new equipment would allow Box39 to develop parts with more complex geometries. After spending months evaluating different machine tools, the company purchased a Model UMC-750 5-axis universal machining center from Haas Automation Inc., Oxnard, Calif.

Box39 produces a custom motorcycle part on its Haas UMC-750 5-axis machining center. Image courtesy Box39.

The machine has an integrated, dual-axis trunnion table and is equipped with an inline, direct-drive, 40-taper spindle. The trunnion allows manufacturers to position parts at almost any angle for five-sided machining or to provide simultaneous 5-axis motion for contouring and complex machining.

"We chose the Haas UMC-750 to improve the quality and artistic value of our products," Belyakov added. "This machine meets the quality standards demanded by the motorcycle market and makes it easy to work with a large tool overhang and quickly generate a lot of chips."

After purchasing the 5-axis machine tool, the company needed CAM software to go with it and purchased an ESPRIT package from DP Technology Corp., Camarillo, Calif. "We looked for software capable of programming 3-axis and 5-axis milling that was compatible with our SolidWorks CAD software," said Igor Bystrov, designer at Box39. "We selected ESPRIT because it includes a Haas-certified post-processor and a Haas UMC-750 virtual model. Another factor was the strong training and technical support provided by DP Technology in Russia."

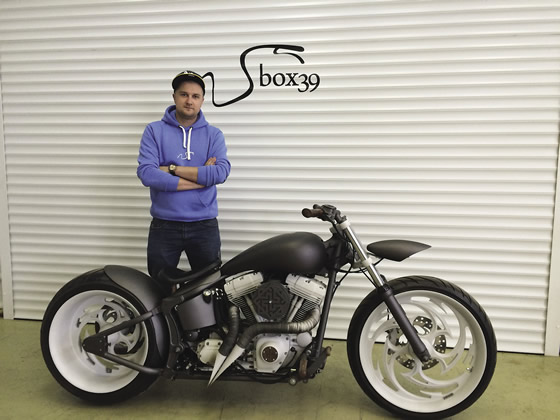

Vladislav Belyakov jumped from a career in financial services to motorcycle parts manufacturing in 2011 with Box39, a custom motorcycle shop located in St. Petersburg, Russia. Image courtesy Box39.

By late 2014, Box39 received its ESPRIT licenses and the engineers were trained on G and M codes before creating CNC programs for the Haas machine. "Since that point we have produced many CNC programs and continue to increase our programming skills," Belyakov said. "We're glad to have the option of viewing the simulated toolpath with this software. We use this feature every day, especially for 5-axis machining."

These tools have already helped Box39 solve many unique challenges faster than they thought possible. "The next step will be purchasing a lathe. Without it, further development of custom components will be difficult," Belyakov said. "This is just the beginning of our journey. The combination of a modern CNC machine and CAM software is helping us create beautiful and powerful bikes."