Microfinishing shifts gears

Microfinishing shifts gears

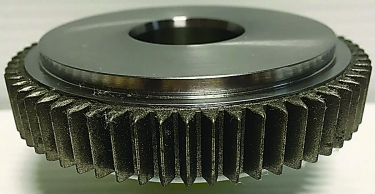

Microfinishing can make a high-quality gear even better by reducing surface roughness.

When Profilator GmbH & Co. KG introduced Hard Scudding a few years ago, the company called the gear-making process "ground changing." Now, the Wuppertal, Germany-based developer and manufacturer has followed up with its microfinishing process, which is designed to further improve gear making.

Microfinishing occurs after Hard Scudding and intends to make a high-quality gear even better by reducing surface roughness.

Like other finishing processes, microfinishing reduces friction. By increasing pitting resistance and thereby reducing fatigue on gear teeth, microfinishing after scudding extends gear life.

Profilator developed the microfinishing tool. Images courtesy of S. Knoy

"Microfinishing is a dry process," said Scott Knoy, president of Profilator's U.S. subsidiary, German Machine Tools of America Inc., Ann Arbor, Michigan. "It runs without cutting fluids and does not rely on minimum quantity lubrication technology."

A diamond-plated tool developed by Profilator is central to microfinishing. The tool allows a user to remove about 20µm of stock per flank. This amount does not substantially affect the gear geometry yet improves the quality of the surface finish.

Among the benefits is noise reduction. Knoy said increased use of hybrid and electric vehicle technology has led to gears rotating at higher velocities.

"Smoother surface finishes lead to quieter gears, significantly reducing the audible noise levels associated," he said.

To demonstrate the effect of Hard Scudding alone versus Hard Scudding followed by microfinishing, GMTA provided Ra and Rz measurements of surface finish on sample gears. When Hard Scudding alone was applied, Rz measures—which compare the tallest peak and lowest valley in the surface—were 2.0μm and 1.7μm for the right and left profiles, respectively, and 1.6μm and 1.3μm for the right and left leads, respectively. In turn, when both Hard Scudding and microfinishing were applied, measures decreased to 0.8μm for both the right and left profiles and 0.7μm and 0.6μm for the right and left leads, respectively.

These results are comparable to abrasive gear finishing processes that are considerably more expensive and require machining fluids and fluid filtration systems, unlike the dry microfinishing process, Knoy said.

He noted GMTA's data about cycle times. For example, working with a standard 125mm to 140mm ID automotive ring gear, Hard Scudding requires about 25 to 40 seconds for cutting and about 12 seconds for loading and unloading stock. Microfinishing requires about 20 seconds more, meaning an average cycle time of about 64 seconds for the two processes. As microfinishing is developed further, the company anticipates a 10 percent reduction in the combined process, bringing the average expected time to under a minute for an automotive ring gear.

Users have several choices for how to incorporate the new technology with existing Profilator equipment. One option is to use microfinishing as a stand-alone process on a scudding machine. A second method involves using the two technologies in sequence: first Hard Scudding, then microfinishing. A third way would be to simultaneously apply the two processes using a double-spindle Scudding machine. Knoy said part geometry ultimately should determine the optimal path.

For more information about German Machine Tools of America, call 734-973-7800 or visit www.gmtamerica.com.