A milling tools overview

A milling tools overview

An array of milling tools is available, including endmills, facemills and plain mills. Typical milling applications include facing, filleting or edge cutting, profiling, slotting, pocketing and blind slotting.

An array of milling tools is available, including endmills, facemills and plain mills. Typical milling applications include facing, filleting or edge cutting, profiling, slotting, pocketing and blind slotting.

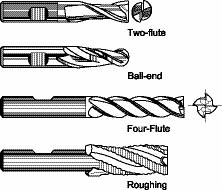

There are several common endmill designs. Two-flute endmills with square ends are applied because they can make plunge cuts into the work like a drill and cut sideways. Their end teeth extend to their centers to allow plunge cuts. Some 3-flute endmills can also perform plunge cuts. Both 2- and 3-flute endmills are suitable for milling nonferrous metals. Two-flute endmills with a ball end produce rounded-bottom slots or filleted edges.

Four-flute finishing endmills with a square end make smoother cuts than 2-flute endmills and stay sharp longer, but cannot make plunge cuts. These tools are best suited for cutting ferrous metals. Four-flute roughing endmills remove metal faster with less horsepower, cutter deflection and vibration than 4-flute finishing endmills, and their chipbreakers produce smaller, more controllable chips.

Courtesy of All images: Pamela J. Tallman

Common endmill designs include (from top to bottom): 2-flute endmill, 2-flute ballnose endmill, 4-flute finishing mill and 4-flute roughing mill.

The helical shape of an endmill's flutes reduces chatter. In operation, one or more points of the helical flutes remain in contact with the workpiece and cut metal at all times. This presents a continuous load to the machine instead of a pulsing load, which occurs each time a tool with a straight flute begins and ends contact with the work. Although making helical flutes is more complex and costly than straight ones, the reduction in chatter and the finer finish they produce is worth the extra cost.

Various common options are available for solid endmills. They are available for right-hand or left-hand cutting. Left-handed cutters are used when the direction of cutting forces must be reversed to avoid stressing the workpiece. In addition, endmills are offered with varying flute lengths, including stub, regular, long and extra long. Endmills can also have tapers. They are commonly tapered at ½°, 1°, 1½°, 2°, 3°, 5°, 7°, 10°, 15°, 20° and 25° per side. These are especially useful in moldmaking to provide draft, or taper, to ease the release of the molded product.

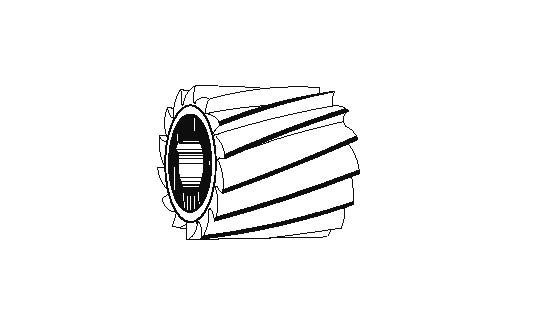

A plain milling cutter is able to rapidly remove a large volume of metal.

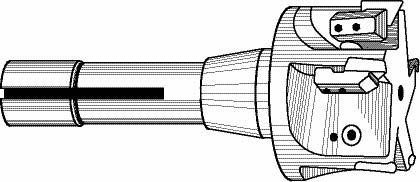

A facemill tooled with inserts.

Shell endmills cut on both their face and sides to impart a fine surface finish. Common diameters are from 1¼ " to 6 ", with flutes cutting from ½ " to ¾ " deep. Because of horsepower and rigidity limitations, vertical knee mills are limited to smaller shell mill sizes. Larger diameter ones can be applied to effectively mill aluminum and plastics.

Facemills are applied to smooth large, flat surfaces and to rapidly remove large volumes of metal. Facemills that accept inserts are available in a range of diameters, typically from ½ " to 3 ". When run on vertical knee mills, lack of mill frame rigidity and the resulting chatter limit those machines to smaller diameter facemills. Facemills are more suitable for massive C-frame mills. When facemilling softer materials, such as aluminum and plastics, larger diameter facemills can be used without chatter.

Plain milling cutters are usually applied on horizontal machining centers on an arbor supported at both ends. Horizontal endmilling machines provide the power and rigidity needed to fully utilize the high metal-removal rates possible with plain milling cutters. However, a horizontal milling attachment permits the use of plain milling cutters on vertical knee mills. This is a useful accessory, even though a vertical knee mill must take lighter cuts than a horizontal mill because of rigidity and chatter issues. In a vertical knee mill with a horizontal milling attachment, the plain milling cutter removes more metal faster than other cutters. In some instances when lacking a horizontal milling machine, using several cutters on the same arbor is simply the best way to do the job. Plain mills are usually wider than the workpiece and cut completely across it.

Plain side milling cutters are similar to plain milling cutters, but they can also cut on their sides. Plain side milling cutters also cut slots, cut off heavy metal bars, smooth faces and cut material into strips. They can be mounted on an R8 toolholder with a single-end support but are best employed in a horizontal milling machine or in a horizontal milling attachment on a vertical knee mill, which is more rigid. Like the plain milling cutter, plain side mills can be mounted with other milling cutters to take multiple cuts simultaneously. CTE

About the Author: Frank Marlow, P.E., has a background in electronic circuit design, industrial power supplies and electrical safety and has worked for Avco Missile Systems, Boeing, Raytheon, DuPont and Emerson Electric. He can be e-mailed at [email protected]. Marlow's column is adapted from information in his book, "Machine Shop Essentials: Questions and Answers," published by the Metal Arts Press, Huntington Beach, Calif.