More reasons for reuse

More reasons for reuse

Take advantage of options that make it simpler and cheaper to recycle fluid

Machine shops that routinely dispose of metalworking fluids after machining are essentially pouring a valuable commodity down the drain, according to proponents of recycling these fluids. Yes, some might agree, but what about the complications and costs of recycling? In reply, however, proponents can point to a variety of products and practices that can make the process easier and more economical.

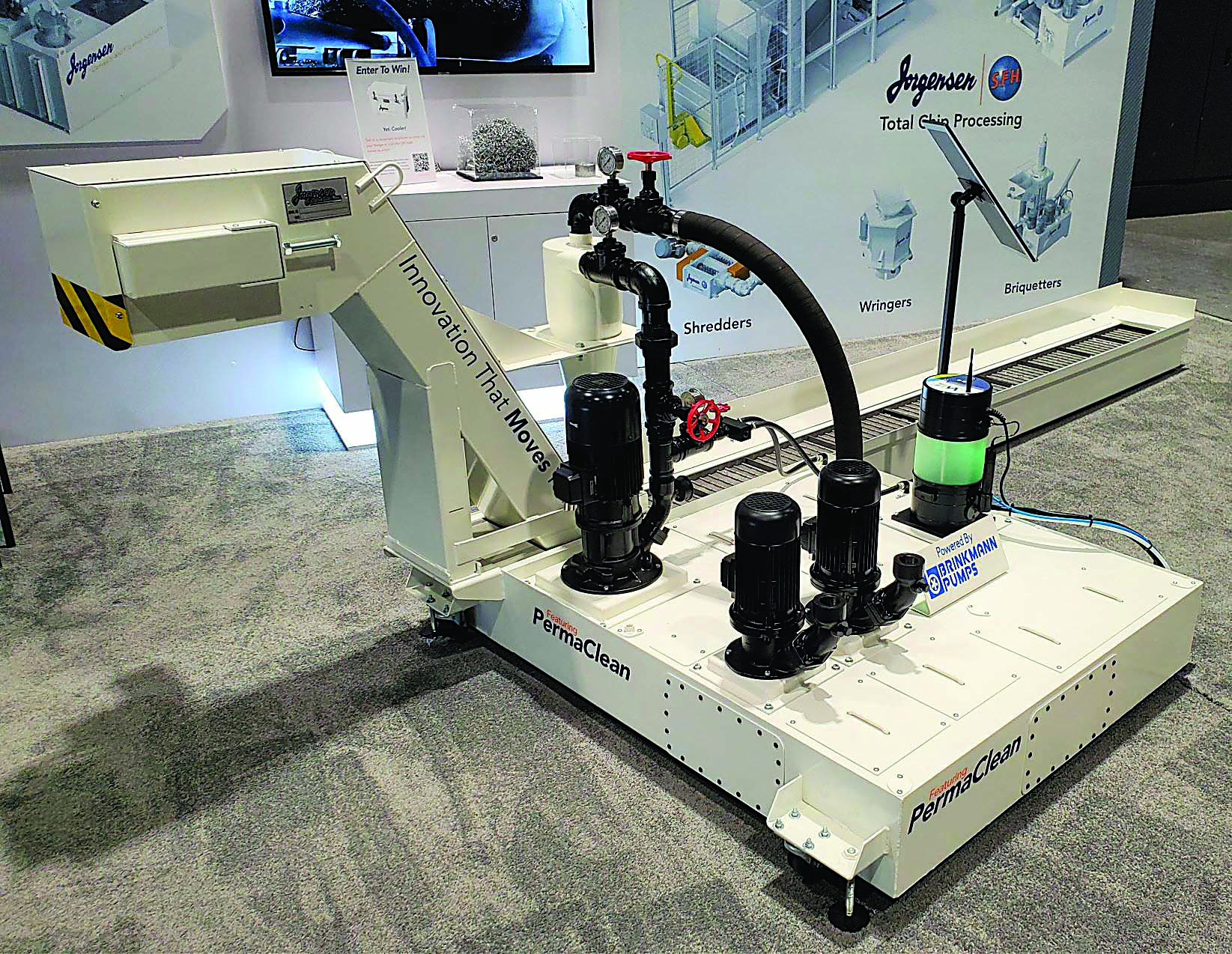

One new product that falls into this category should be welcomed by shop maintenance personnel. Sold by Jorgensen Conveyor and Filtration Solutions in Mequon, Wisconsin, the PermaClean filtration option is said to make coolant tanks virtually maintenance-free when combined with cyclonic filters that rely on centrifugal force rather than filter media to remove contaminants. According to the company, PermaClean eliminates sludge buildup by using eductor nozzles to keep coolant in motion in a tank. This in turn keeps chip particulates suspended in the coolant, thereby preventing them from settling in the tank. PermaClean can be incorporated into any of Jorgensen's multistep filtration systems, the company notes..

The Guardian is a turnkey fluid recycling system designed for easy installation and operation. Image courtesy of Prab" data-entity-type="file" data-entity-uuid="30dcb8de-aef6-497c-8f23-f01fb046792a" height="645" src="/wp-content/uploads/legacy/inline-images/Image%201%20Guardian.jpg" width="671" />Another coolant recycling option on the market is billed as a turnkey system designed for easy installation, quick startup and simple operation that minimizes operator involvement and training. Called the Guardian, this centralized system removes tramp oils and suspended solids from contaminated coolant and also controls bacteria to reduce worker exposure to fluids that are hazardous to health. Manufactured by Prab Inc. in Kalamazoo, Michigan, the Guardian slashes new fluid purchase costs, providing a rapid return on investment, said Mike Hook, director of sales and marketingAt the shops that Prab deals with, he said the average payback period for a coolant recycling system is less than nine months."After that," Hook said, "they're printing money."Operators Not NeededAt many plants, Hook pointed out that one of the main challenges is maintaining the correct lubricant concentration in water-based solutions due to evaporation and other factors. This requires regular testing of the fluid and adjustment of the concentration when necessary to get it back into the proper range. To take these tasks out of the hands of operators, Prab provides an automatic alternative with the Guardian called the AC3 Fluid Monitor. This unit is an in-line process refractometer that tests fluid that is continuously circulated through it. When the concentration level drops below the proper ratio, the system adds more chemicals and less water until the desired concentration level is reached.Another automatic option for monitoring coolant concentration is the Liquidtool Sensor, developed by Hasle, Switzerland-based Liquidtool Systems AG. Magnetically attached to a surface close to a coolant tank, the sensor regularly pumps cutting fluid and measures both its concentration and temperature. This data is sent to the cloud-based Liquidtool Manager, which analyzes it in real time. If corrective action is necessary, a notification is sent to the facility where the coolant came from.PermaClean technology prevents chip particulates from settling in coolant tanks, which is supposed to make them virtually maintenance-free when combined with cyclonic filtration. Image courtesy of Jorgensen Conveyor and Filtration Solutions

"The fluid is not allowed to go over-concentrated or under-concentrated, and that allows you to get the most out of it," said Brett Reynolds, senior applications engineer at Blaser Swisslube Inc. in Goshen, New York. (Switzerland-based Blaser Swisslube and Liquidtool Systems are sister companies.)

Besides employing the Liquidtool Sensor, Blaser Swisslube's customers trying to make their coolant-recycling job easier can opt for fully synthetic coolants from the firm.

These coolants are generally a little easier to recycle because they lack an emulsifier and therefore "don't hang on to foreign oils like an emulsion would," Reynolds said.

Helpful Practices

As for practices that can make coolant recycling easier, Hook recommends standardizing on a single fluid. He said shops that do this don't have to worry about keeping different fluids segregated and possible cross-contamination.

He added, however, that the one fluid chosen "often has to be a little more robust to (handle) all the processes in the plant. But many of the new cutting fluids are capable of that."

Hook also pointed out that major recycling obstacles can be avoided when a schedule of regular preventive maintenance is followed. This helps ensure that fluid will be recycled before it reaches a rancid state.

"Once tramp oil takes over and bacteria growth begins, it's very difficult to kill it all off," he said. "In most of the systems out there today, if a sump goes to rancid and starts creating all the problems that are associated with that, the fluid has to be disposed of."

Perhaps the easiest way to facilitate fluid reuse is to slow down a chip conveyor. Karl Kleppek, president and COO of Jorgensen, pointed out that a fast-moving conveyor belt results in more coolant "carryout" into a chip hopper. When a chip conveyor is slowed, however, there's a better chance that coolant will stay on the conveyor and flow back to the tank. He said, though, that shops must make sure to maintain a conveyor speed that is adequate to handle the chip load of their machines.

Keep It Cheap

When shops consider whether to take on fluid recycling, a task that is outside their core competencies, some certainly will wonder about outsourcing the job. Although the idea of turning the whole process over to external experts has obvious attractions, there are good reasons not to outsource in this case.

Hauling hazardous materials "is expensive and difficult to acquire in certain areas of the country," Hook said. "So usually, you're going to want to keep the fluids in-house."

Reynolds said shops looking for relatively inexpensive equipment for in-house coolant cleaning can purchase different types of skimmers that remove floating tramp oil from the surface of fluids. But for just a little more money, he noted, shops can purchase a unit called a coalescer, which uses a filter medium to remove oil from fluids circulated through the coalescing chamber. After filtering, the fluid is pumped back into the sump.

A coalescer "is basically a kidney filtering on a constant basis," he said, adding that he prefers coalescers to skimmers for removing oil. But he also cautioned potential users that coalescers must be cleaned regularly "or you can have problems. So make sure you stick to the (maintenance) schedule."

Supplier Guidance

With all the fluid filtration and recycling options on the market today, how do shops that lack knowledge and experience in this area make the right purchasing decisions?

"You can go online and look at different types of equipment, but they may not be ideal for your situation," Reynolds said. So in the end, "you may spend more money than you need to."

Therefore, the first step he recommends is consulting your metalworking fluid supplier.

"Any decent fluid supplier works with various manufacturers in the field," Reynolds said, "and they can certainly give you some ideas and options."

Blaser Swisslube, for example, works with all manufacturers of fluid filtering and recycling equipment and isn't paid to send potential customers to any of them, he said. Instead, he said the company has other motivations for assisting customers looking to purchase equipment.

"We want their fluid to last as long as possible because resources are limited and we want to take care of the planet from an environmental standpoint," Reynolds said. "And we want customers to get the most benefit and longevity out of their products before they have to replace them."

Options for Recovering Usable Fluid From Waste

Separating metalworking fluids from machining waste products can be worthwhile. Here are some common options for tackling the job:

- Chip wringers/centrifuges. These devices, which spin collected chips, generally reclaim approximately 96% to 98% of the coolant clinging to the chips, said Karl Kleppek, president and COO of Jorgensen Conveyor and Filtration Solutions. Recovered coolant is captured in a tank under the system and then pumped to a tote for reuse. In some cases, coolant is filtered prior to reuse. He said these systems can be very complex or simple manual systems.

- Chip briquetters. Briquetters squeeze collected chips into a briquette both to reduce the size of the collections and to reclaim expensive coolant for reuse. A briquetter usually costs twice as much as a wringer, he said, due mainly to the hydraulics needed by the briquetting unit to crush chips.

"If coolant reclamation is the only requirement of the system, the wringer is typically the most cost-effective option, reducing a company's investment and offering a quicker ROI," Kleppek said. However, "when a company is looking to reclaim coolant and briquette chips to reduce space, then the briquetter could be the better option."

Like Jorgensen, Prab Inc. offers products that separate metalworking fluids from machining waste. These include:

- Magnetic separators. Used in pre-filtrations processes to reduce the contaminants reaching downstream industrial filtration equipment, these devices use high-intensity ferrite or rare-earth magnets to remove ferrous material from water-soluble and neat oils.

- Vacuum filtration systems. Featuring permanent or disposable media, vacuum filters facilitate fluid reclamation by eliminating high volumes of sludge produced by machining centers and grinding operations.

While separating sludge from cutting fluids and recovering fluids from swarf and filter cake boost fluid reclamation rates, Prab points out that additional filtration measures can do even more. For example, the use of tramp oil separators and centralized filtration systems can reduce a shop's new fluid purchases by as much as 75%, according to the company.

"As a rule of thumb, we've seen that 75% is a pretty good estimate of the savings," said Mike Hook, director of sales and marketing. "So if a plant is spending $100,000 a year on new coolant purchases, they can pay for a $50,000 (filtration) system in nine months or less."

— William Leventon