Multiple methods are available for deburring holes

Multiple methods are available for deburring holes

Burrs present a hazard to those who handle parts during and after the manufacturing process. The deburring method can have a major impact on cycle time, cost, quality and customer satisfaction.

Burrs present a hazard to those who handle parts during and after the manufacturing process.

Burrs can also break off in holes, causing significant problems. Deep oil holes in crankshafts, for example, must be burr-free to prevent small caps or slivers of material from entering the fluid system.

A burr can also have a negative impact on mating parts and how the fit and finish of components and assemblies look and perform.

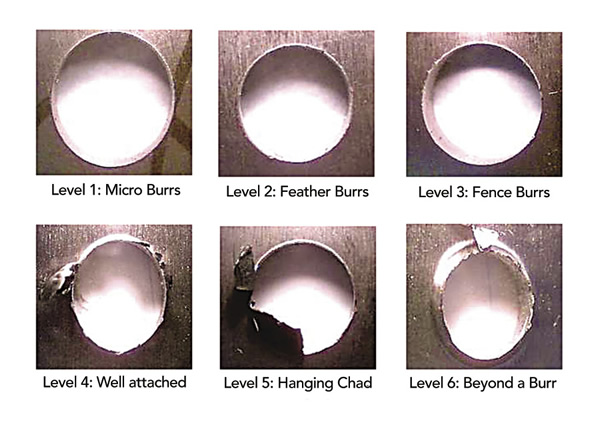

There are five levels of burrs, plus one that goes beyond what is generally considered a burr. All images courtesy E-Z Burr Tool.

Customers demand that parts be smooth to the touch, aesthetically pleasing, have holes that are without burrs and, typically, have a nice looking chamfer.

When a hole is drilled, a burr is usually generated. The deburring method can have a major impact on cycle time, cost, quality and customer satisfaction.

In countries where labor costs are low and reducing cycle time is not critical, the most common way to deburr is with a manual scraping tool. These tools usually have a handle with replaceable blades. Hand scraping is time-consuming, but the tools are inexpensive.

However, repetitive use of these tools can increase the chance of long-term injuries, such as carpal tunnel syndrome. Cuts, too, are a reality, and the resulting edge consistency will not be as good, compared to an automated tool.

Out of Touch

When burrs are hard to access, such as those in the cross-holes of tubular components, there are more-efficient ways to deburr than by hand. Common methods include applying brushes, mounted points, sphere-shaped rotating tools, flexible abrasives and rotating tools with replaceable HSS or carbide blades or inserts.

Deburring tools can be used in high- and low-volume jobs and can be run on a wide range of equipment, including hand drills, drill presses, manual mills, CNC mills and lathes, and multitask machines.

Some deburring tools resemble one-piece tuning forks: a split design with two cutting "tines" that squeeze together to pass through a hole. In operation, the tool is inserted until it touches the rear of the hole, then on the retract feed it cuts the back of the burr.

The industry, however, offers a better alternative in the form of quick-change blades and inserts, which can be replaced in minutes or even seconds. These eliminate the need to remove the old-style tool and replace it or send it to the cutter grinding department for resharpening. In addition, quick-change designs are more accurate and robust. Some are even adjustable and allow the blades to be changed while the tool remains in the spindle.

When a burr is on a challenging workpiece material and hard to access, the long life and strength of a deburring tool that accepts carbide inserts can be the most cost-effective choice, especially for production applications. Inserts are available with aggressive cutting angles for difficult-to-deburr applications.

Long-reach tools and stubby lengths are readily available, too, and toolmakers can design and produce application-specific specials. For example, they can design tools with fixed pockets to accept chamfer inserts and combination tools to drill, deburr and chamfer in one pass.

Burrs and Beyond

Burrs are classified by size (as shown on page 82). These include micro-, feather- and fence-type burrs, which are referred to as levels 1, 2 and 3, respectively. These burrs can be easily and effectively removed with a single pass of a deburring tool fitted with an HSS or carbide blade. In addition, an adjustable-size chamfer can be dialed in for a great-looking result.

Level 4 is more challenging and may require more-aggressive cutting angles or coated carbide inserts for best results. This level of burr is usually beyond the capabilities of hand-scraping tools or brushes but can still be effectively removed and chamfered in one pass.

Level 5 is like a "hanging chad." More cutting force is required to detach it, but it can elicit major customer complaints if it isn't completely removed. It can be removed by application of the proper deburring blade, in combination with a slower feed rate, or by a secondary pass.

The last classification, level 6, is actually beyond the definition a burr. Instead, it is extruded material that is mushrooming from the hole in a way that is typical when drilling low-carbon steel and other challenging materials.

In the case of a level-6 protuberance, the deburring tool will cut the outer portion of the extrusion but generally will not be able to completely remove it. It would be better to switch to a drilling process that leaves less extruded material around the hole. The more cleanly the hole is drilled, the smaller and more manageable the burr will be.

Custom Deburring Tool Ends Hub Hubbub

Skyway Precision Inc. needed a better way to reach the back of an 80-lb. (36.3-kg) component to deburr holes. The nodular-iron component was an 11.6"-dia. (294.6mm) hub with 22 holes, 10 at 0.425" (10.795mm) in diameter and 12 at 1.093" (27.762mm) in diameter.

Plymouth, Mich.-based Skyway was removing the heavy hub and placing it on a workbench to manually deburr the rear of the holes by applying a countersinking tool in an air drill. This method was cumbersome, time-consuming and costly. Not only did the extra handling require additional man-hours to complete the part, but the countersinking tool was expensive and lasted only a day or two.

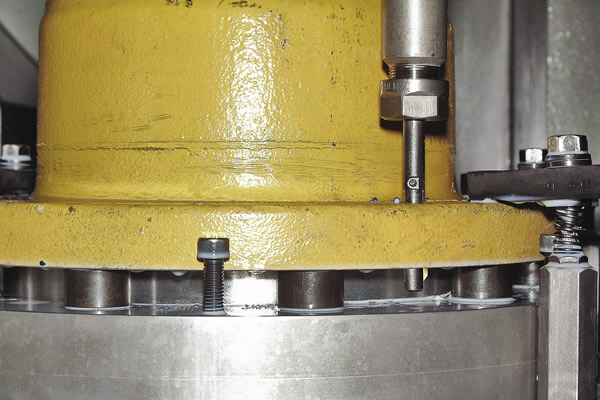

A special from E-Z Burr Tool deburrs an 80-lb. nodular iron hub at Skyway Precision.

The company turned to nearby E-Z Burr Tool Co. to design and make a custom 9"-long (228.6mm) tool for the application. To accommodate Skyway's specifications, the tool ran at a spindle speed of 550 rpm and a cutting speed of 8.8 ipm (223.5 mm/min.) when deburring the 1.093" holes. In addition, the tool gave Skyway the ability to deburr the back of the holes while the hub remained in the machine.

For the smaller holes, a standard-length tool deburred the top and bottom of the holes in one pass. It ran at 1,750 rpm and 11 ipm (279.4 mm/min.)

The E-Z Burr deburring tool saved Skyway 15 to 20 minutes per part and dramatically reduced the injury risk and additional manpower requirements. Eliminating the countersinking tool also saved money. Plus, the tool accepts E-Z Burr carbide inserts, which last a month before needing replacement. This process led to further engineered improvements, such as using a short pilot drill to start the hole and chamfer the top of the larger holes. The pilot hole eliminated the "walking" and tool breakage problems and prolonged the life of the expensive long drill.

—E-Z Burr Tool Co.