A new bonded superabrasive material

A new bonded superabrasive material

PCD oxidizes when cutting materials such as iron, cobalt, nickel, chromium and vanadium because of the high temperatures generated while cutting. Although not as hard, PCBN possesses superior chemical inertness compared to PCD.

PCD oxidizes when cutting materials such as iron, cobalt, nickel, chromium and vanadium because of the high temperatures generated while cutting. Although not as hard, PCBN possesses superior chemical inertness compared to PCD.

Researchers at Sichuan University's Institute of Atomic and Molecular Physics have been working on a material that combines the best attributes of PCD and PCBN to create a new superabrasive material. The hope is that cutting tools made from this material will outperform currently available tools.

"Diamond and cubic boron nitride could readily [be combined and] potentially fill the performance gap because of their affinity in structure lattices and covalent bonding character," explained Duanwei He, professor at Sichuan University. "However, the idea has never been demonstrated because samples obtained in previous studies were too small to test their practical performance."

He and his colleagues at the University of Nevada and the Chinese Academy of Sciences detailed this research in Physics Letters, published by the American Institute of Physics.

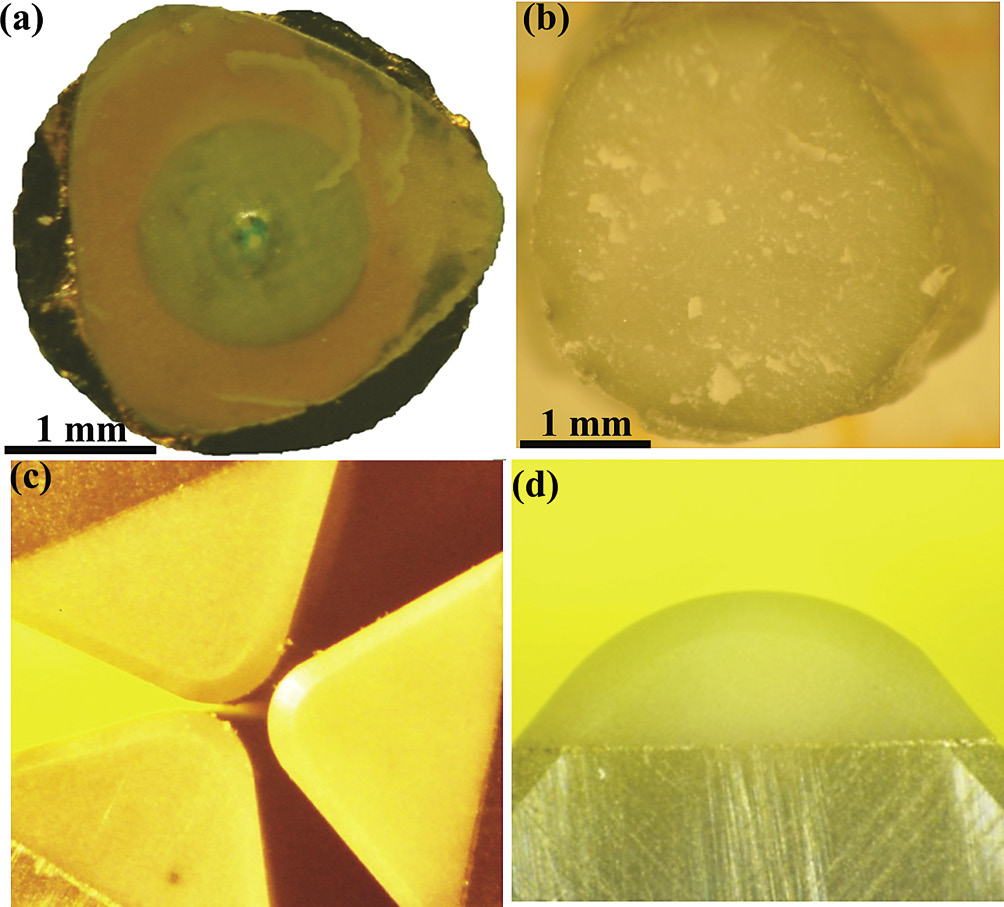

Sichuan University's Institute of Atomic and Molecular Physics has developed a PCD/PCBN superabrasive material. Samples (a) and (b) were synthesized at 20 GPa and 2,500° K over a copper screen to exhibit the material's transparency. Polished rake faces of the PCD/PCBN cutting tools are shown in (c) and (d). Image courtesy Sichuan University.

To synthesize the PCD/PCBN material, the researchers subjected a homogenous mixture of diamond and CBN powder to a vacuum furnace at 1,300° K (1,880° F) for 2 hours, then pressed the material into 3.5mm (0.138") pellets under pressure greater than 15 gigapascals and temperatures above 2,000° K (3,140° F). They then polished and sharpened the pellets into cutting implements.

The researchers tested the cutting performances of their tool on a CNC lathe, cutting hardened steel and granite bars. They found that the PCD/PCBN tool rivaled PCBN's wear and tool life when cutting steel and exhibited significantly less wear when machining granite. The tool also demonstratApplieded better high-speed cutting performance than either PCBN or PCD.

The next step involves developing synthesis technology to bring the process up to industrial-scale production. The researchers will also determine what other materials can be produced utilizing similar processes.

For more information about Sichuan University, Chengdu, China, visit www.scu.edu.cn.

About the Author: Matt Jaster is a former senior editor of CTE.