Nissei Industry

Nissei Industry

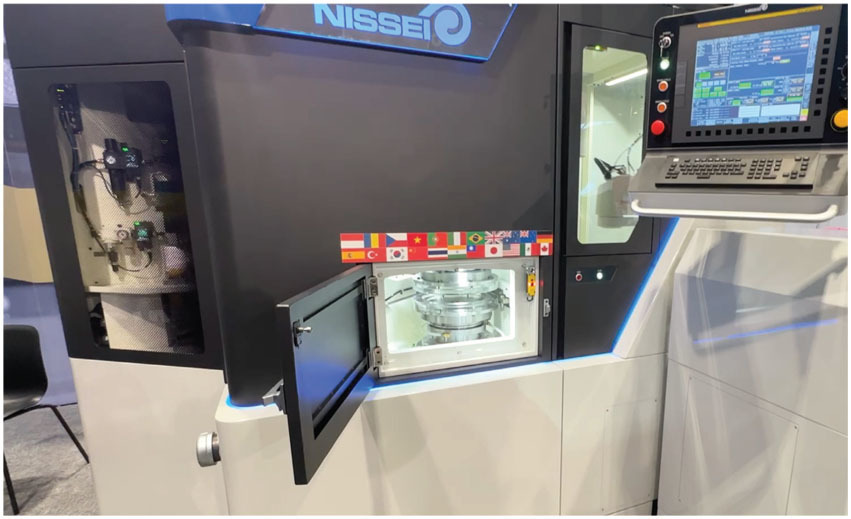

Nissei Industry Corp. showcased its VP3-400RW vertical double-disc grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine during IMTS 2024. Making its debut in the U.S. market, the VP3- 400RW

issei Industry Corp. showcased its VP3-400RW vertical double-disc grinding machine during IMTS 2024. Making its debut in the U.S. market, the VP3- 400RW machine is particularly suited for high-demand industries such as automotive and bearing manufacturing.

Nissei's new grinder is built to handle high volumes with precision. Among the highlights of the VP3-400RW:

- The machine allows for the simultaneous grinding of both sides of a component, drastically reducing processing times.

- An innovative 180º indexing system ensures seamless part transfer between grinding wheels, enabling consistent and repeatable performance.

- The upper grinding wheel adjusts dynamically during the grinding process to achieve precise finishes.

- The grinder can process up to eight components in a single cycle, maximizing productivity and minimizing downtime.

- The grinder also features advanced automation capabilities. During operation, the machine precisely places inserts or workpieces onto plates, streamlining the handling process. This automation not only improves efficiency but also minimizes operator intervention, further enhancing productivity.

This double-disc grinder excels in processing materials such as metal rings and ceramic blocks, offering the precision and reliability required for these demanding applications. Nissei anticipates significant interest from manufacturers focused on high-volume production and tight tolerances.

At IMTS, Nissei's demonstration unit highlighted the grinder's potential, even as a non-operational model. Attendees observed the automation and design features, which showcased the company's emphasis on precision engineering and innovative manufacturing solutions.

By introducing this double-disc grinder to the U.S. market, Nissei is positioning itself as a leader in precision grinding solutions. The company's commitment to innovation ensures that manufacturers have access to cutting- edge technology that meets modern production demands.

Visit the Nissei Industry website for more information.