Partnership boosts productivity

Partnership boosts productivity

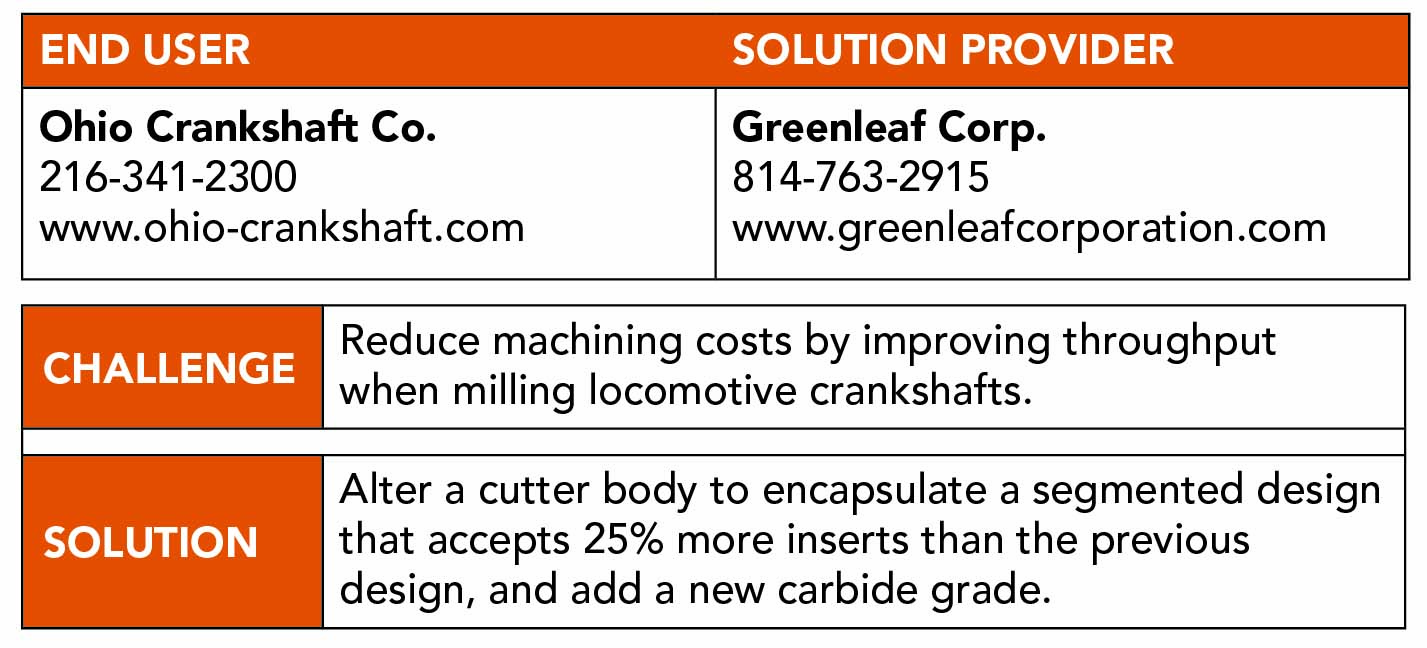

Greenleaf and Ohio Crankshaft join forces to enhance throughput when milling locomotive crankshafts

Developing a partnership between a cutting tool manufacturer and a part manufacturer is one avenue to boost machining productivity. Greenleaf Corp. and Ohio Crankshaft Co. are long-standing companies that joined forces to significantly enhance throughput, said Bernie Kirwin, OCCO's engineering manager, who started working on the shop floor in 1984. (Last year, Saegertown, Pennsylvania-based Greenleaf celebrated its 75th anniversary, and Cleveland-based OCCO, which produces large crankshafts, camshafts and other critical components for locomotive and marine diesel engines, pumps and other reciprocating equipment, turned 100.)

"We did a lot of testing of carbide back in the day," he said. "We found that Greenleaf developed a good product, and we developed a good relationship with Greenleaf."

As a result, OCCO talked to the toolmaker when OCCO's team determined that there must be a more efficient way to mill locomotive crankshafts from 5046 steel forgings, which was taking about four hours or more to machine a shaft with up to two indexes of the carbide inserts. When the inserts need to be indexed, the cutter must be removed from OCCO's crankshaft milling machine tool, and machining stops for about an hour.

Denny Carpenter, sales and service engineer at Greenleaf, inspects milling cutter inserts and segments. Image courtesy of Greenleaf

"We wanted to be able to use some existing cutter bodies and apply new technology to them," said Denny Carpenter, sales and service engineer at Greenleaf.

The cutter bodies were altered to encapsulate a segmented design, which allowed more insert pockets, increasing the number of inserts by 25%. The design enables OCCO to change worn segments.

The redesign permitted the company to increase the feed rate about 25%, Kirwin said, noting that feeds range from 50.8 to 1,524 mm/min. (2 to 60 ipm).

"We try to maintain a 0.012" (0.305 mm) chip load," he said.

Kirwin said the cutter rotates and oscillates about the x- and y-axes as it cuts while the workpiece

remains stationary, and coolant is not applied.

In addition to changing the design of the cutter body, OCCO switched to Greenleaf's GA5036 carbide grade. Carpenter said the grade has a higher level of cobalt than the previous grade that was used, enhancing toughness to cut steel forgings at a fairly high speed and extending tool life, while the multilayer chemical vapor deposition coating of the grade effectively resists wear and heat.

He said the insert geometry also is well suited for the task at hand.

"We did some pretty extensive edge preps to determine what was needed for the carbide grade and for the application," Carpenter said.

Kirwin said the cutter rotates and oscillates about the x- and y-axes as it cuts while the workpiece remains stationary, and coolant is not applied.

In addition to changing the design of the cutter body, OCCO switched to Greenleaf's GA5036 carbide grade. Carpenter said the grade has a higher level of cobalt than the previous grade that was used, enhancing toughness to cut steel forgings at a fairly high speed and extending tool life, while the multilayer chemical vapor deposition coating of the grade effectively resists wear and heat.

He said the insert geometry also is well suited for the task at hand.

"We did some pretty extensive edge preps to determine what was needed for the carbide grade and for the application," Carpenter said.

Furthermore, OCCO's machine was upgraded mechanically to allow higher cutting speeds. Working with the machine builder, the company installed a variable-frequency drive to enable the cutter to be programmed conveniently to different spindle speeds.

"It's just a matter of plugging in some numbers," Kirwin said. "We are able to program that rpm so we can get a higher surface footage and increase our feed rates."

He said the company saw its biggest improvement when milling a crankshaft for OCCO's 16-cylinder 710 model, cutting the four-hour cycle time in half and eliminating the need to index the inserts until the part was completed. The company also manufactures crankshafts and camshafts for eight-, 12- and 20-cylinder locomotives.

In some cases, costs were reduced by a factor of four, but further gains are being targeted.

"We are continuously looking at how we can improve the design of the cutters, the segments," Carpenter said. "In engineering, we have some initial work being done on the next generation."