Pulling Chips

Pulling Chips

This month Cutting Tool Engineering covers a chip-pulling system developed for more efficient turning.

When executives at Murata Machinery Ltd. approached researchers at Nagoya University in Japan about chip-jamming issues in the machine tool builder's turning equipment, it started an interesting dialogue between industry and academia. Chips were jamming, causing downtime and a hazardous environment for the operators.

"Although the use of chipbreakers is the long-standing rule in high-performance turning, chips from high-ductile material and thin chips produced in finishing operations can't be broken reliably with chipbreakers," said Dr. Burak Sencer, assistant professor, mechanical engineering, at Oregon State University, who worked with the team in Japan.

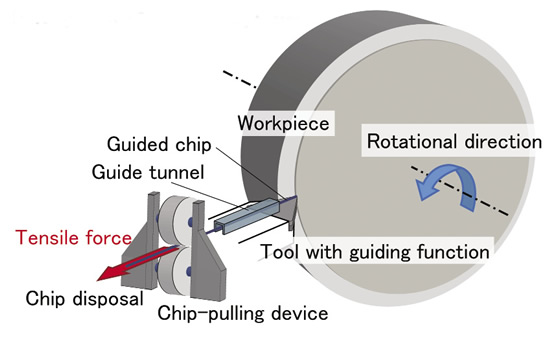

The Nagoya research team wanted to create a suitable and reliable alternative to chip breaking by utilizing the cut chip itself for process optimization. The idea was to not break the chip, but actually dispose of it by pulling it through a guide tunnel via an electromechanical device.

The researchers started the project by examining chip flow. "We wanted to suppress the side curl, so we put microgrooves on the insert's rake face to ensure chips would flow through the grooves instead of curling back to the workpiece or tool shank," Sencer said.

Sencer and the team experimented with different pitches and depths to determine the most effective shape. The vertical (upcurl) of the chips proved challenging because the upcurl caused the chips to jam just outside the tunnel. They investigated a suction method and tools with various rake angles to suppress that, according to Sencer.

Researchers at Nagoya University in Japan developed a chip-pulling system to alleviate jamming that can occur when turning low-carbon steel and aluminum. Image courtesy Burak Sencer.

The focus then changed to designing a mechanical device that gently pulls the chip through the guide tunnel. "We had to measure the tension and determine a good pulling speed, as well as a good pulling force," Sencer said. "If you pull too fast, the chip breaks and you're back at square one."

They mounted sensors under the pulling device to determine the forces the chip could handle.

"We can control the cutting feed, cutting speed and DOC in turning operations, but by controlling the chip tension, you're adding an entirely new element," Sencer said. "This can lead to a more efficient manufacturing operation."

If chip tension can be regulated with the pulling device, for example, the cutting force reflected on the workpiece can be cancelled, according to Sencer. "In other words, it is like peeling a piece of fruit. As you cut the apple you pull the skin, which actually cancels the force that the cutting tool (knife) exerts on the workpiece. This allows precision turning of long, extremely slender parts. You push with the cutting tool and pull the chip to keep the part straight," Sencer said.

The research, particularly the chip tension control, has received interest from both scientists and engineers, and the project led to the installation of a working vacuum system for chip removal in Murata's turning machines.

Chip-pulling, however, is still a work in progress. Sencer is developing a more compact version that may utilize magnets to better control chip flow at different speeds and feeds. He is working on new proposals to improve the original chip-pulling concept.

For more information, contact Burak Sencer at [email protected] or visit www.mime.oregonstate.edu.

About the Author: Matt Jaster is senior editor of CTE. Contact him at (847) 714-0174 or [email protected].