Rusty versus damaged parts

Rusty versus damaged parts

The Grinding Doc defines and eliminates grinding burn.

Dear Doc: We're getting visible grinding burn on the unground surface. Why there? And how do we get rid of it?

The Doc replies: First, let's be careful with definitions as there's a lot of ambiguity and overlap in what people refer to as grinding burn. Here's how I define it in "The Book of Grinding."

There are four types of thermal damage in steels: 1) oxidation burn, which most people call grinding burn; 2) over-tempering, also called thermal softening; 3) residual tensile stresses; and 4) rehardening burn, also called white layer.

Type 1 is simply iron oxide — that is, rust — and visible to the naked eye. Types 2, 3 and 4 are invisible to the naked eye and can be revealed only with testing (nital etch, Barkhausen, X-ray diffraction, microhardness, etc.). Some people call types 2, 3 and 4 grinding burn, which I try to avoid. Type 1 doesn't affect the strength of the material — it's simply a thin layer of iron oxide. Types 2, 3 and 4, which I refer to as genuine thermal damage, do affect the strength of the steel.

All steel surfaces develop a thin oxide layer. But at higher temperatures, that layer becomes thicker, more visible and more colorful. Does that brown-yellow-blue iron oxide layer (type 1) mean that you have genuine thermal damage (type 2, 3 or 4)? Maybe. Maybe not. You'd have to test it.

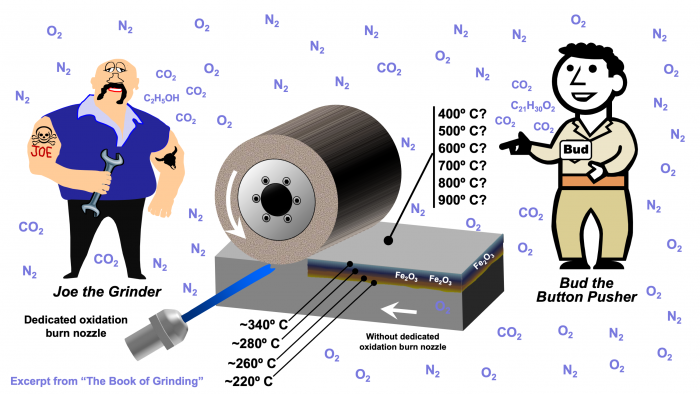

"But wait," you say. "Your figure shows high temperatures on the ground surface and lower temperatures on the unground surface. So why do I have oxidation burn only on the unground surface?" Things became hotter on the ground surface than they did on the unground surface, but you don't see oxidation burn on the unground surface. That is because of two reasons: 1) There was coolant on the ground surface instead of air (oxidation requires oxygen), and 2) the trailing edge of the wheel ground away any oxidation burn that did develop. Heat conduction caused high temperatures (but not very high) on the unground side surface, where we didn't grind it away. Hence, we see oxidation burn on the unground surface.

You want to get rid of that iron oxide oxidation burn, but how? Since it begins at such low temperatures, you're going to have a hell of a time using the regular methods of reducing grinding temperature — a sharper dress, a different wheel, improved mainline cooling, etc. In fact, there's only one way to reduce or remove oxidation burn: Direct a separate cooling nozzle at the oxidizing region on the unground surface.

This works for two reasons: 1) It reduces temperature, slowing that oxidizing chemical reaction, and 2) it starves the region of oxygen. (Air is 20% oxygen, and coolant has close to 0%.) The figure, pulled from "The Book of Grinding," explains.

But be careful. Now that you've reduced or even eliminated those brown, yellow and blue marks, Joe the Grinder might be tempted to say, "Hey, Bud, look. Grinding burn is gone. Let's crank up those feed rates." Now you've got genuine thermal damage, but you can't see it. There are no brown-yellow-blue marks, just a severely weakened steel. It's a clean yet damaged workpiece. That's a bad situation.