Scrape to the point

Scrape to the point

Whether done manually or with a powered device, scraping guide ways is critical to machine tool performance.

The debate about roller-type linear guide ways vs. conventional box ways has raged for decades. Linear guide ways are fast, accurate and relatively easy to install in both high-end and low-cost, commodity machine tools. Proponents say linear guide ways create less heat and friction and don't have the stick-slip action associated with box-style ways, which should make them more accurate. Linear guide ways are commonly found on many high-speed machining centers and Swiss-style lathes, where lightning fast rapid-traverse rates and light cuts are the rule.

On the other hand, old as the Industrial Revolution itself, box ways are known for their ability to carry heavy loads and take heavy cuts. They have superior vibration damping ability, but require a master craftsman to install. Compared to linear guide ways, box ways are less likely to be damaged in a crash, and, in most cases, offer longer service life. They, too, can be extremely accurate and are often used in jig boring, grinding and other machine tools that require submicron precision.

VIDEO

View a hand scraping video supplement courtesy Okuma America.

Big Business

While the argument about which is better won't be settled anytime soon, both styles of guide ways should be appropriately sized for the machine tool, of sufficient quality for the application and properly installed. Poorly designed or improperly installed guide ways—box or linear—will doom even the best-designed machine tool, regardless of technological merits. For machine builders and service companies alike, one aspect of guide way selection is especially important: Box ways can take some serious elbow grease to scrape and substantial skill to install.

"For a large machine, it can easily take several weeks to scrape the ways," said Scott Ashworth, president of capital equipment sales and service company KRC Machine Tool Services, Independence, Ky. KRC is rebuilding a boring mill, with an approximate 8'-long (2.44m) table and two bearing surfaces that are each 6" (152.4mm) across. "Even with two guys tag-teaming the work, it takes a long while to complete a project this size."

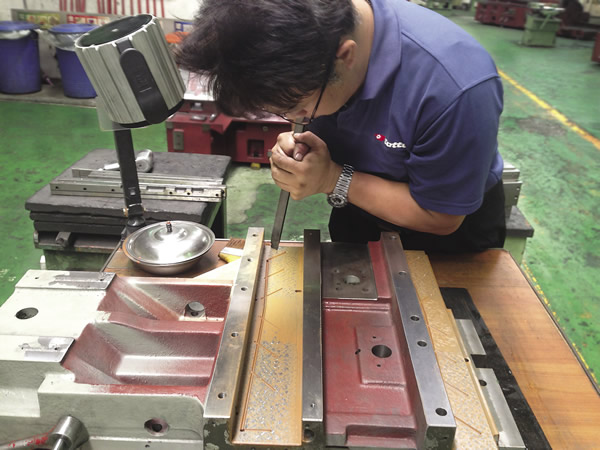

Knowing where to scrape and how much to remove takes years of experience. Image courtesy KING-WAY Scraping Consultants.

Ashworth said a substantial percentage of his business is the remanufacturing and retrofitting of old, heavy-duty machines, such as horizontal boring mills and vertical turret lathes. Many have nonfriction material, such as Turcite or Rulon, on the way surfaces. These materials increase the weight capacity of machine tools while reducing the tendency of precision load-bearing surfaces to "stick" together.

Ashworth explained that hand scraping creates small pockets on the surface to hold oil and provide lubrication, but, even with a properly scraped surface, some metal-to-metal friction occurs. Because of this, when the ballscrew is first turned, there's a small amount of "windup" until the machine starts moving, at which point it tends to jump forward. "Granted, this is a very minute distance—microns, perhaps—but it can be an important factor with very fine, detailed machining and heavy loads," he said. "This is why many builders opt for Turcite."

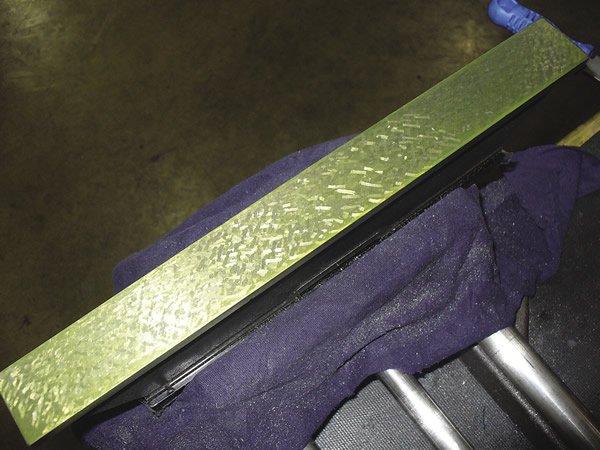

Turcite and comparable nonfriction way surfaces are made of polytetrafluoroethylene (PTFE), a thermoplastic that is often blended with bronze and other additives before being "skived" into sheets 12" to 24" wide × ¼", or less, thick (304.8mm to 609.6mm × 6.35mm). It is glued to the cast iron or steel substrate, then scraped in the same manner as metal box ways to create oil-bearing surfaces. This ubiquitous material offers a frictional coefficient roughly 20 percent that of scraped metal-on-metal ways.

A technician (top) power scrapes the high spots on a metal way surface. A finished way (below) is ready for installation. Images courtesy Busch Precision.

A Lasting Legacy

Whether metal or plastic, hand scraping requires application of a flat, carbide-tipped blade, to make the way flat, and then "flaking" the finished surface. The following six steps describe the process:

1. Make an initial "cross scrape" to clean and prepare the surface.

2. Remove any loose chips and dust, then apply a small amount of mineral oil and "stone" the surface to remove burrs.

3. Apply a thin layer of bluing paste to the surface.

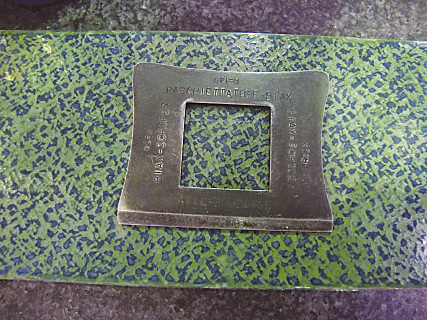

4. Rub the way on a surface plate, which removes the colored paste from the high spots.

5. Scrape the high spots, then repeat steps 2 through 4 until the surface is completely flat and the machine's geometric requirements are met.

6. Flake the surface to create oil pockets, then clean and stone it one final time.

Bob Behnke, a machinist at Busch Precision Inc., a Milwaukee contract manufacturer and machine repair company, said scrape marks are like fingerprints of the person who worked on the machine. "Everybody has their own individual pattern. Over time, you look at enough of them and you're able to recognize who did the work. We have people who scraped here 25 years ago, and I can still pick out which machines were theirs."

Behnke said the amount of scraping, the depth of each individual mark and the distance between them (points per square inch) depends on a number of factors. A very worn machine could require grinding or machining to true the geometry, followed by a complete scrape job. A light rebuild may only need to be "freshened up" to make surfaces flat and create the proper amount of oil retention. Machines that will see heavy loads call for deep scraping, where light-duty machines can be effective with shallower scrapes. In each case, the craftsman follows the same basic process, but makes technique adjustments based on skill level, experience and the application needs of the machine tool.

"There's a lot to it," Behnke said. "The length of time spent scraping any particular surface or machine comes down to how many high spots there are to begin with, how much resistance is acceptable when the machine tool traverses back and forth, the amount of lubrication that's needed and the size of the way surface. It takes a lot of experience, but it's also physically demanding. You have to push on the blade and really dig in if you're going to get a deep scrape, which is the best way to assure longevity in the machine tool."

Sticking to the Plan

Aside from strong forearms and a steady grip, successful scrapers have a solid game plan. "You can't just go at it randomly," Behnke said. "You have to be very meticulous, scraping first in one direction, then the other. That breaks up the lines and gives a nice, uniform pattern."

Okuma America Corp. Applications Engineer Robbie Williams agrees. The Charlotte, N.C., machine builder hand-scrapes wherevertwo moving metal surfaces meet to reduce the wear and tear on machine tools. "You can turn the machine off and walk away from it for weeks, and when you turn it back on again, you'll still have that oil in there," he said. "Because of this, there's never any actual metal-to-metal contact."

Measuring the points per inch on a scraped Rulon142 wear strip. Image courtesy KING-WAY Scraping Consultants.

Robbie Williams, applications engineer for Okuma America, conducts an in-booth hand scraping seminar at IMTS. Image courtesy Okuma America.

Part of the machine rebuilding process involves cleaning all surfaces and removing old paint and grime. Image courtesy KRC Machine Tool Services.

The challenges of scraping rise exponentially as machines become larger. Williams said a small lathe might take 10 to 30 hours to complete, whereas a horizontal toolchanger. See automatic toolchanger." title="CNC machine tool capable of drilling, reaming, tapping, milling and boring. Normally comes with an automatic toolchanger. See automatic toolchanger." aria-label="Glossary: machining center">machining center can take far longer. That's because more things can go wrong as the machine size increases—ways might be concave or convex and can twist from one end to the other. All geometric irregularities must be removed so the surfaces mate perfectly through careful, patient scrapes with a carbide blade.

Williams has been scraping for 16 years, but said he still learns new things every day. He teaches a weeklong class on hand scraping at York Technical College and has conducted in-booth seminars at IMTS. Becoming proficient at hand scraping takes several years as an apprentice, he said, working under the tutelage of a journeyman scraper.

Tools of the Tradesman

One such journeyman is Richard King, who learned the art of hand scraping from his father and has passed down what he learned to more than 20,000 students. The owner of KING-WAY Scraping Consultants Inc., Cottage Grove, Minn., King said his profession is a lot like detective work. "Say you have a machine that's been running the same production job over and over again. Naturally, it's going to wear out in one area and have to be rebuilt. At that point, you have to take it apart, clean it and inspect every component before scraping anything."

King added that the process begins with leveling the machine to factory specifications. The weight of the toolchanger or turret, the electrical cabinet hanging off the back, the spindle cartridge all impact the pitch and yaw of the machine tool and must be accounted for when scraping the machine ways back to square. King said most builders recommend laser leveling their machines, but a high-quality set of levels can achieve similar results in the right hands.

"Once the machine is level, you'll need a scraper, some nondrying bluing paste, a precision surface plate and a set of straight edges," he said. "We recommend power scraping, because it's much faster than hand scraping and—if used properly—achieves better results." (See sidebar below.)

King said the comparison between hand scraping and power scraping is little different than drilling a hole with a hand drill vs. an electric one. He admits power scraping takes a different approach and can be overdone, but that's all part of the learning process. However it's done, scraping is just a small part of building or rebuilding machine tools. "It's a very important part, but is probably only 25 percent of the total picture," he said. "The rest involves fitting the pieces together properly, cleaning and refurbishing and restoring the mechanics of the machine tool. Still, there's a lot more to scraping than just making a flat surface. Knowing where to scrape and how much to remove takes years of experience. It's definitely a skilled trade."

Power up

Matt Milhomens, inside technical sales at DAPRA Corp., Bloomfield, Conn., said power scraping is at least twice as fast as manual scraping.

"We did time studies at General Motors. One guy's productivity went up by 54 percent, another went up 76 percent. It doesn't matter if you're a small person or someone with huge muscles, power scraping eliminates a ton of hard work," Milhomens said.

The BIAX power scraper offers adjustable stroke length and speed. Image courtesy DAPRA.

The BIAX power scraper was invented in the early 1950s by Walter Wetzel, brother of DAPRA's owner, Rudi Wetzel. It incorporates an electric motor to drive a reciprocating carbide-tipped blade, mimicking the back and forth motion of hand scraping. The blade speed and stroke is adjustable—up to 1,900 strokes per minute, with stroke lengths from 0" to 0.8" (20mm). Milhomens said operating the BIAX is about as difficult as steering a bicycle. All that's required is to set the proper stoke and speed, and then push. Long, fast strokes are suitable for roughing and heavy material removal, whereas short, delicate strokes flake the finished surface or get into tight corners.

"We've sold [power scrapers] to companies all over the world, from machine builders and reconditioners, to manufacturing companies that rebuild their own machines in-house," Milhomens said. "Even the folks who've been hand scraping for years like how easy the BIAX operates. There are none of the aches and pains you get from gripping a blade all day long, and the cutting method can be customized to your own personal preference."

The price for a BIAX scraper is from $2,700 to $3,500, inexpensive enough that even some hobbyists purchase one. Milhomens admits that hand scraping is never going away, and is preferred by many for finishing and fine detail work, but power scraping will at least do most of the heavy lifting. "It just makes life a lot simpler."

—K. Hanson

Contributors

Busch Precision Inc.

(414) 362-7300

www.buschprecision.com

DAPRA Corp.

(800) 243-3344

www.dapra.com

KING-WAY Scraping Consultants Inc.

(844) 833-6334

www.handscraping.com

KRC Machine Tool Services

(888) 4-KRC-MTS

www.krcmachinetoolservices.com

Okuma America Corp.

(704) 588-7000

www.okuma.com/americas