Shedding light on lasers

Shedding light on lasers

Lasers offer major steel-cutting advantages, but there are also reasons to pass.

If you machine steel but don't know much about lasers, it might pay — and even pay big — to learn what this special light can do at a shop. In the process, however, don't let the shining attractions of a laser machine blind you to its downsides.

As for those attractions, state-of-the-art lasers offer fast, economical and accurate cutting of sheet metals and thick plates with high cut-edge quality, little to no post-processing and minimal drawing-to-part time, said Rouzbeh Sarrafi, senior applications scientist at IPG Photonics Corp. a laser manufacturer in Oxford, Massachusetts. He said lasers on the market do a good job of cutting almost all metals, and the lasers are particularly good at cutting steels.

"Steel is one of the best materials that you can cut with lasers in terms of quality and throughput," he said. "All grades of steel have been shown to cut really well with lasers."

Productivity and Savings

Although lasers carry a hefty price tag, they're very inexpensive to operate, so per-part costs are the lowest of any cutting option, said Brett Thompson, laser technologies and sales consulting manager at Trumpf Inc. in Farmington, Connecticut. And while not quite as accurate as chip-producing machines, he said lasers provide good cutting accuracy, along with high productivity.

"So generally," he said, "people are focused primarily on laser cutting because of the throughput they can get."

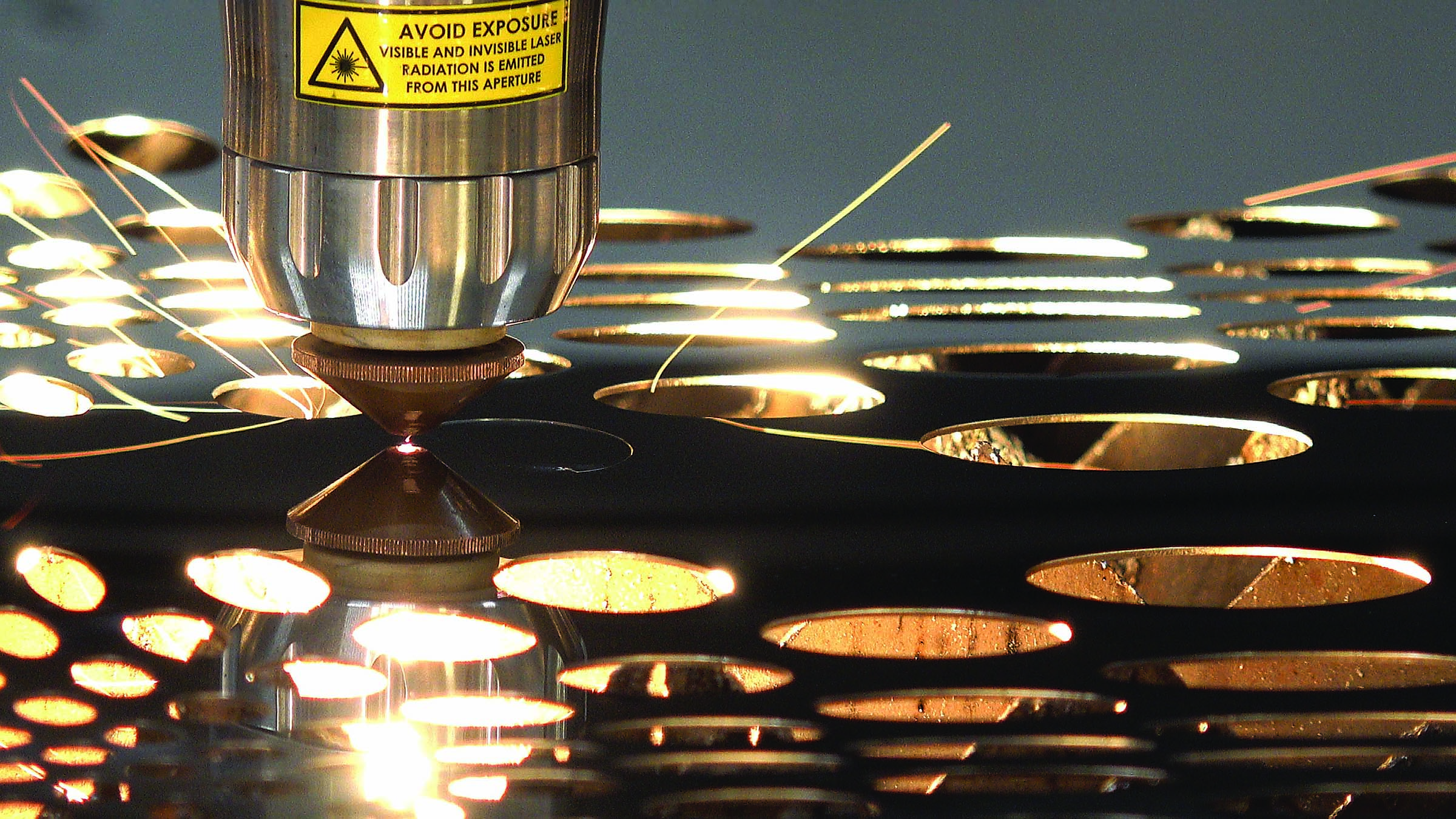

When laser cutting stainless steel (shown at left), different assist gases produce different results. Image courtesy of IPG Photonics

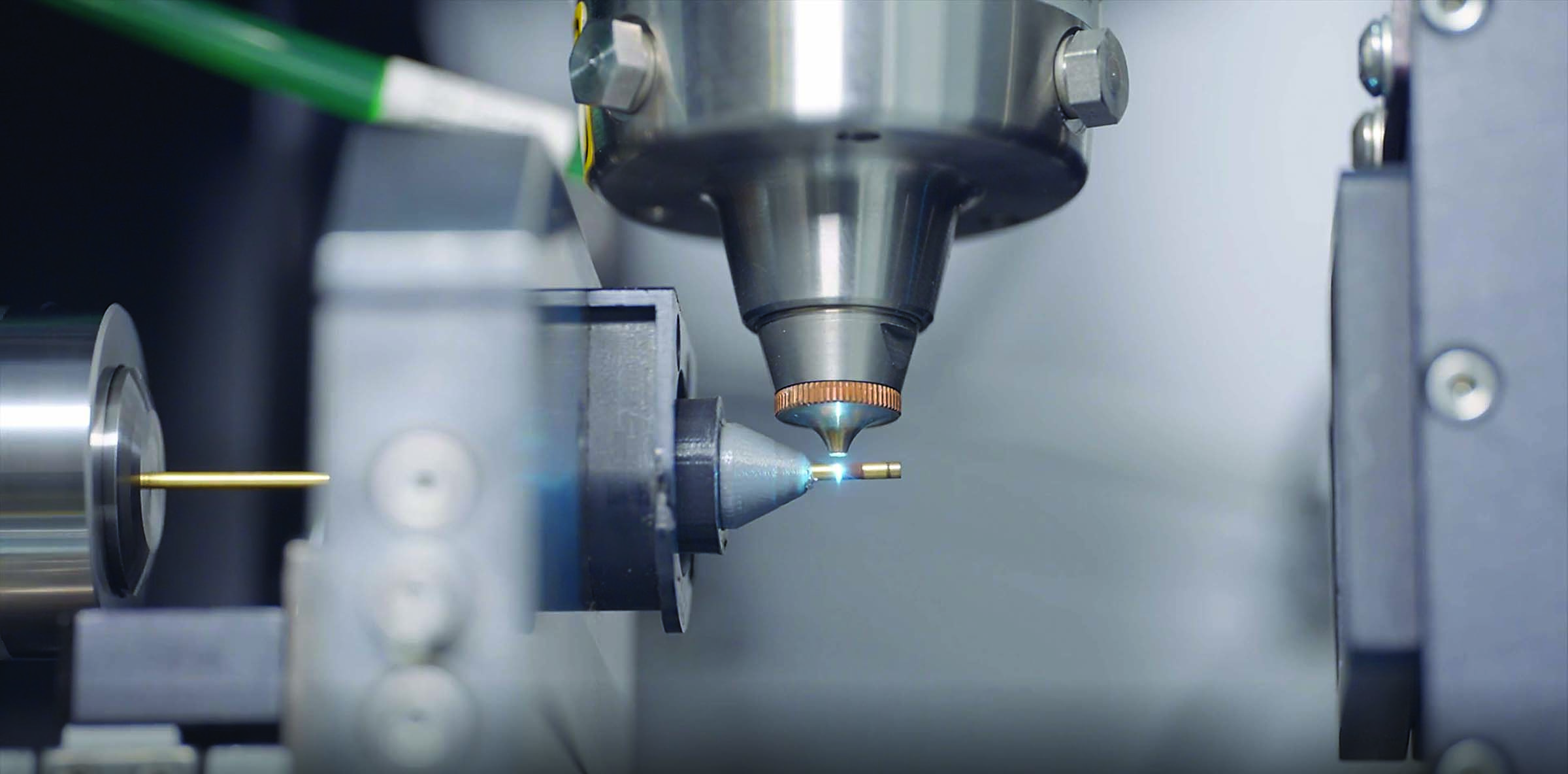

Lasers are an especially attractive option for those trying to meet the challenges of micromachining steel, said Attila Farkas, sales and marketing analyst at Microlution Inc., a Chicago-headquartered subsidiary of GF Machining Solutions LLC. Microlution sells turnkey laser-based packages for machining very small features, such as holes with diameters of about 30 µm (0.001"). He said trying to cut these microscale features with conventional tools results in a good deal of costly tool breakage. And while electrical discharge machining works well for steel micromachining, he said, there are tool consumption costs that are not incurred when cutting with a laser.

What's more, using EDM to shape a small hole requires an initial drilling operation, which adds more time to the process, as well as an additional machine.

With a laser, however, "not only can you create the hole in solid steel, but then you can shape the hole to the final size," said Eric Ostini, head of business development at GF Machining Solutions in Lincolnshire, Illinois.

At IMTS last month, one item displayed by the company was a steel spinneret die. Traditionally, the job of creating the small slotted holes in the spinneret required both milling and EDM machines, he said. Now, though, a single laser machine is all that's needed. Besides eliminating a machine from the process, he pointed out that the laser does its work much faster than the two machines combined.

"It might take three hours to do a spinneret between milling and an EDM," Ostini said, "whereas a laser can reduce that to minutes."

Laser turning can create steel parts with very small diameters. Image courtesy of Microlution

Farkas said lasers have a big advantage over wire EDM in both cycle time and quality when used to make highly precise steel watch gears. EDM, he noted, can have a cost and cycle time advantage if the gear materials to be cut are stacked. But another result of stacking is a loss of repeatability, so to maintain tight tolerances, many high-end watchmakers don't stack materials for cutting.

With a laser, he said, "you might have a higher initial cost, but you're going to make the parts faster if you're not stacking them, and you get higher quality."

Sarrafi said time and cost savings are key reasons that lasers have been replacing punch cutters in the production of steel parts. He noted that laser machines can handle changes in part materials and thickness without any setup or tooling costs. Instead, all that users need to do is to change the process parameters in the controller. Similarly, changes in part geometry are made quickly using what he calls "soft tooling."

"In modern high-power laser machines, you can go from a CAD drawing to cut parts in less than five minutes," he said. And with problems of tool and die wear eliminated, "you can understand how attractive laser cutting can be today."

In addition, Sarrafi pointed out that laser cutting is noncontact, so a laser can be thought of as a blade that never dulls.

"High-quality fiber lasers are so reliable that a cutting recipe (always) will cut with the same speed and quality," he said, "so there's no need to tweak the recipes once set for a certain material."

On the other hand, Sarrafi said punch machines sometimes have an edge over lasers — typically when producing large quantities of parts with relatively simple geometries. In those cases, upfront tooling costs may be justified to punch out multiple parts very fast. Laser machining, by contrast, is a profile cutting process and can be slower in those situations, he said, depending on laser power.

Laser Drawbacks

Compared with other cutting options, lasers are also at a disadvantage when it comes to upfront costs. Consider, for example, femtosecond lasers — advanced lasers with pulse durations of about a quadrillionth of a second — used to machine small features.

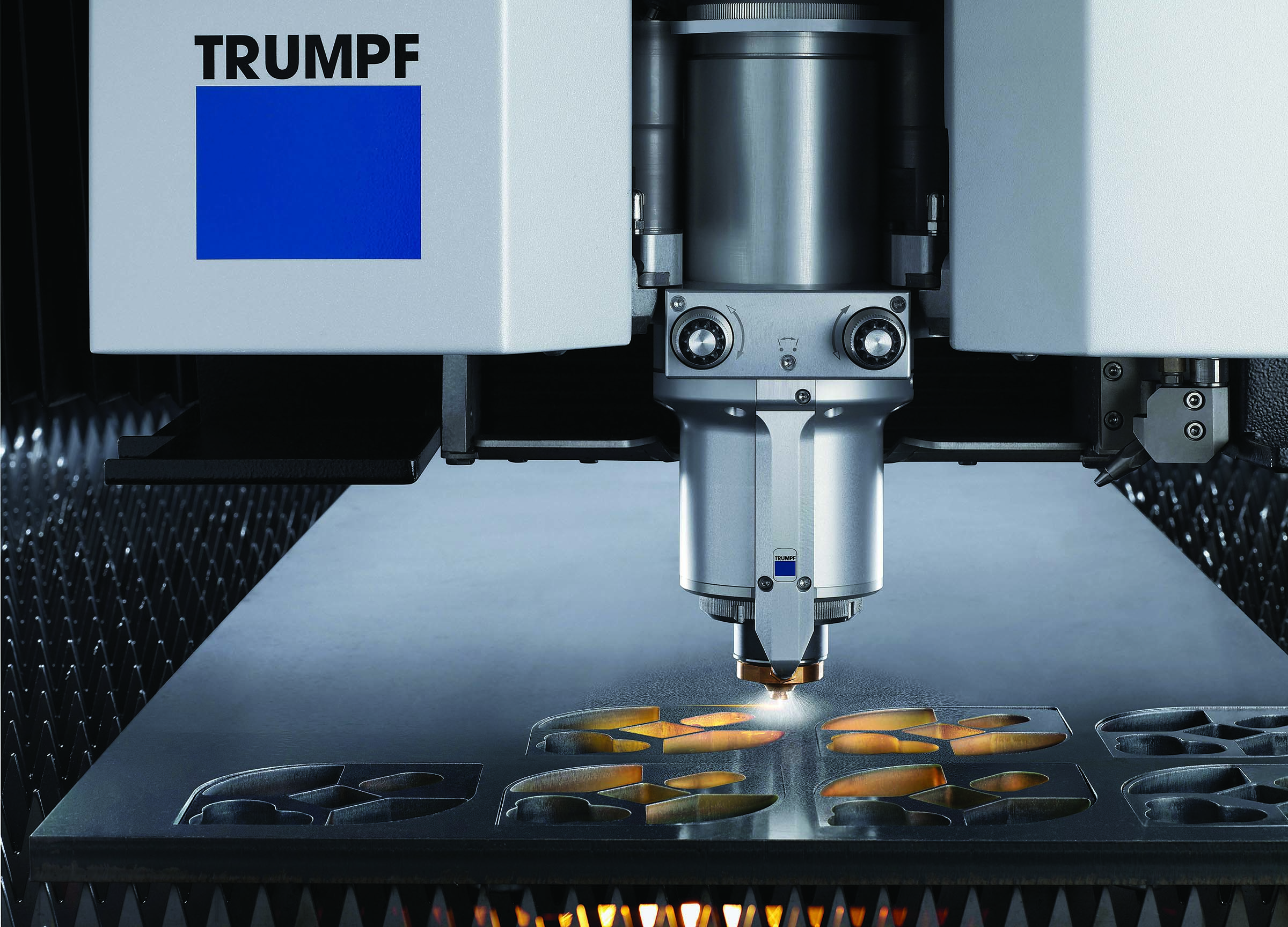

Trumpf's technology enables selective cooling of a workpiece during laser cutting. The purpose is to improve process reliability and allow new geometries when a laser cuts thick mild steel. Image courtesy of Trumpf

"If you're going to a femto," Ostini said, "you're looking at five times the cost of an EDM machine."

Another laser-cutting drawback is that it's a thermal process that produces a heat-affected zone in which the heat produced by laser cutting changes the properties of the material. Thompson said this has caused some industries to shy away from lasers.

"For the longest time, aerospace had completely written off any thermal process," he said, adding that some in the industry are taking a second look at lasers for applications in which the amount of heat imparted to material may not pose a fatigue threat.

Although in most cases lasers cut different alloys and grades of material both quickly and with good quality and consistency, Thompson pointed out that lasers can struggle with inconsistencies in the metal being cut. These include surface inconsistencies like rust and those in the metal, such as small pockets of silica.

Assist Gas Issues

When it comes to types of steel, Sarrafi said the details of the laser-cutting process are different for carbon steel and stainless steel. The main differences include the choice of laser power and so-called assist gas.

For stainless steel, he said nitrogen assist gas provides a shiny, nonoxidized cut surface while high-pressure air lowers cutting costs but produces oxidation on the edge.

As for carbon steel, Sarrafi said it can be cut with oxygen, nitrogen or clean, dry high-pressure air. With oxygen cutting, he explained, most of the process energy is generated by the reaction of oxygen with the iron in carbon steel. The laser is the initiator of the reaction and a supplementary heat source.

"Because of the extra oxidation energy," he said, "you can cut a thicker section of carbon steel at a given laser power compared to nitrogen or air."

Oxygen cutting also results in a smooth cut edge, Sarrafi said, but it is oxidized heavily and the heat-affected zone is much larger than it would be in a nitrogen or air process. In addition, he noted that it is difficult to scale up the speed of an oxygen-cutting process, unlike nitrogen- or air-cutting operations. This is because oxygen cutting requires a certain ratio between energy input from oxidation and that from the laser.

"As a result, you cannot apply too much laser energy in this process, so cutting throughput does not scale up well with increasing laser power," he said. "So cut speed is low with high-power lasers."

In nitrogen cutting of carbon steel, however, Sarrafi said cutting speed scales well with laser power, so carbon steel can be cut very fast with high-power lasers. But he also pointed out that nitrogen is expensive. On the other hand, he noted that cutting with high-pressure air offers the speed advantage of nitrogen cutting without its cost drawback. But to get a high-quality cut in thick carbon steel with air, he said users need high laser power — typically at least 8-kW.

How much of a difference can the choice of assist gas make in a laser cutting process? When cutting 16 mm (0.63") carbon steel with a high-power laser, he said the speed of oxygen cutting remains at about 2 m/min. (6.56') when laser power goes from 10-kW to 30-kW. But when air cutting at 30-kW, he said the speed is over 9 m/min. (29.53'), more than four times faster than cutting with oxygen.

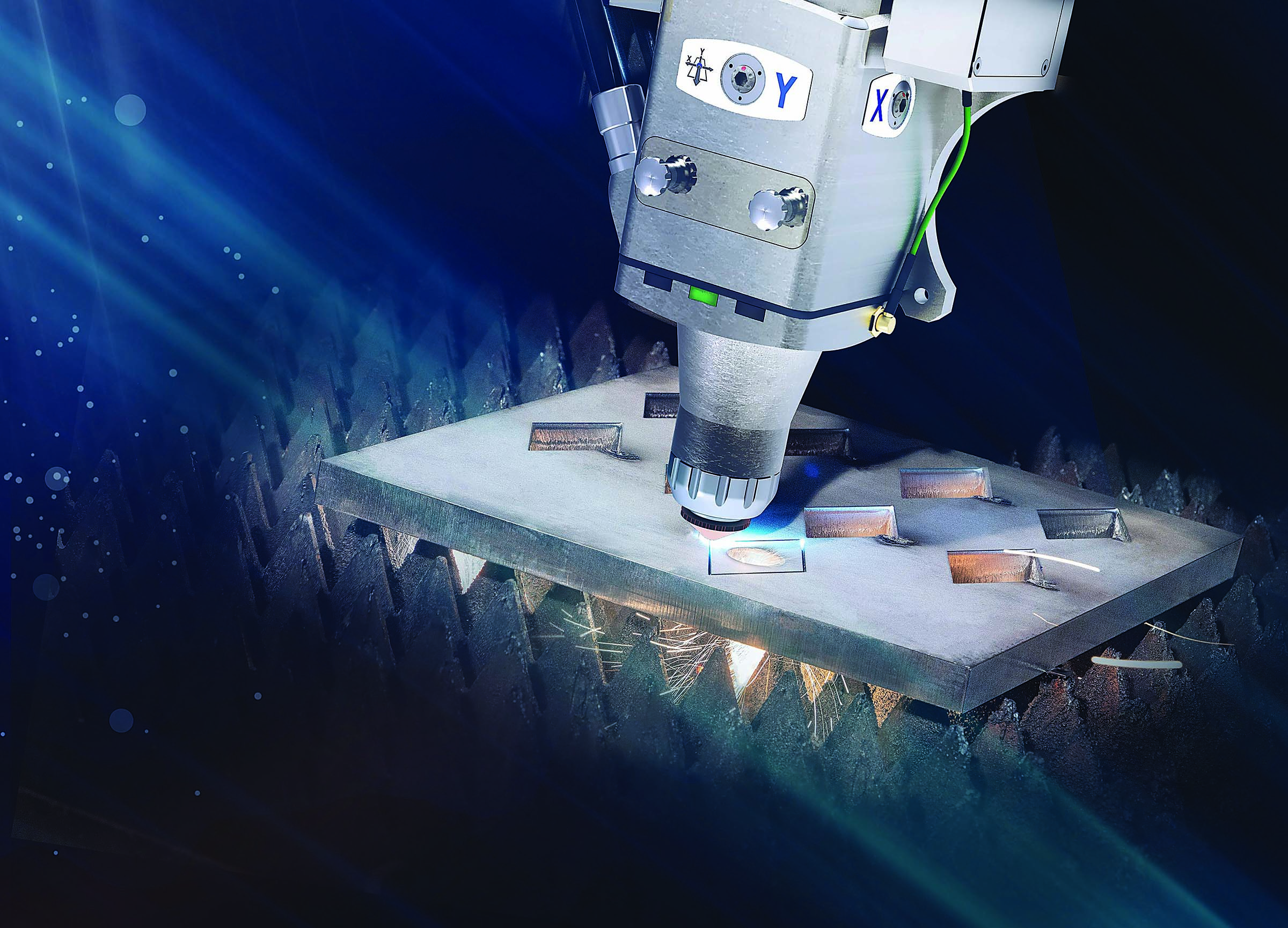

High-power lasers can give a big boost to steel-cutting speeds. Image courtesy of IPG Photonics

"Ultrahigh-power lasers dramatically increase the productivity of cutting thick carbon steel while using air keeps running costs low and yields good, dross-free cut quality," Sarrafi said.

Notable Developments

In addition to working solo, lasers from IPG Photonics are being used to create hybrid machining systems. For example, Marubeni Citizen-Cincom Inc. in Allendale, New Jersey, will add an IPG Photonics fiber laser system to the lathes and turning centers that it sells to its customers, who are engaged mainly in making small medical components from steel tubing. This allows users to do both conventional and laser machining on the same platform to reduce part handling and improve accuracy.

Sarrafi said more good news for laser users is the huge increase in feasible laser-cutting throughput over the past five years compared with other profile-cutting processes, such as plasma, waterjet and EDM. This trend, he said, has been driven primarily by the availability of high-power (10-kW-plus) fiber lasers at a lower cost. To illustrate how much of a throughput difference that a significant boost in laser power can make, he pointed out that the cutting speed of 6.35 mm (0.25") stainless steel with a 4-kW laser is about 3.56 m per min. (140 ipm), but the speed jumps to 35.56 m per min. (1,400 ipm) with a 30-kW laser.

He said 30-kW laser systems do a good job cutting steels up to 76.2 mm (3") thick while 40-kW lasers now can handle steel thicknesses up to 101.6 mm (4").

"Because of their ultrahigh productivity and increased thickness capabilities," Sarrafi said, "lasers with 12-kW power and more are replacing plasma cutters in some applications."

Another development that has boosted the thickness of steels that a laser can cut is widespread use of what Thompson calls a mixed-gas process, in which a small amount of oxygen is added to nitrogen. In addition to allowing thicker cuts, he said a mixed-gas process improves cut quality and bumps up cutting speeds about 20% over the base nitrogen feed rate.

Although lasers can cut thicker metals today, he isn't sure that lasers should be used for that purpose due to the cost of the high-power systems required for the job. For example, he pointed out that a 40-kW or 50-kW laser offers thickness-cutting performance similar to that of a plasma cutter but costs five or six times as much.

"If I'm cutting thin to mid-thick materials, there's nothing that will compare with a laser in throughput, quality or cost per part," Thompson said. "But as the material gets thicker, its benefit over other processes starts to diminish a bit. So I think there's an upper limit where a laser starts to become maybe not the best solution from a practical perspective."