Software cuts turnaround time

Software cuts turnaround time

Walter's Helitronic Tool Studio software combines ease of programming with great flexibility.

By United Grinding North America Inc.

Dew Tool Grinding Services Inc. opened in 1983 as a one-man machine shop, and Tim Kirst became co-owner in 2000. Since starting straight out of high school at an aerospace shop, he has spent his entire career in the machine shop business and has seen a lot. One thing he's certain about is the importance of investing in the latest grinding technologies, including software.

"It's just good business to keep up with the advances in modern manufacturing," he said, "from both a business success and customer experience perspective."

As a specialty toolmaker, Dew Tool Grinding Services always has relied heavily on the software of its tool grinding machines. However, as they aged, the Oak Creek, Wisconsin, shop realized that it needed the functionality and capabilities of newer versions of tool grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" title="Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpi…" aria-label="Glossary: grinding machine">grinding machine software not only to meet customer deliveries for more complex tools but to boost its overall competitiveness.

Dew Tool Grinding Services makes specialty cutting tools for valve and medical device manufacturers, as well as for job shops that produce parts for companies, such as Deere & Co. and Caterpillar Inc. The shop manufactures three types of cutting tools: basic high-speed steel, carbide and carbide-tipped tools. In fact, the company is one of few shops in the area making carbide-tipped tooling.

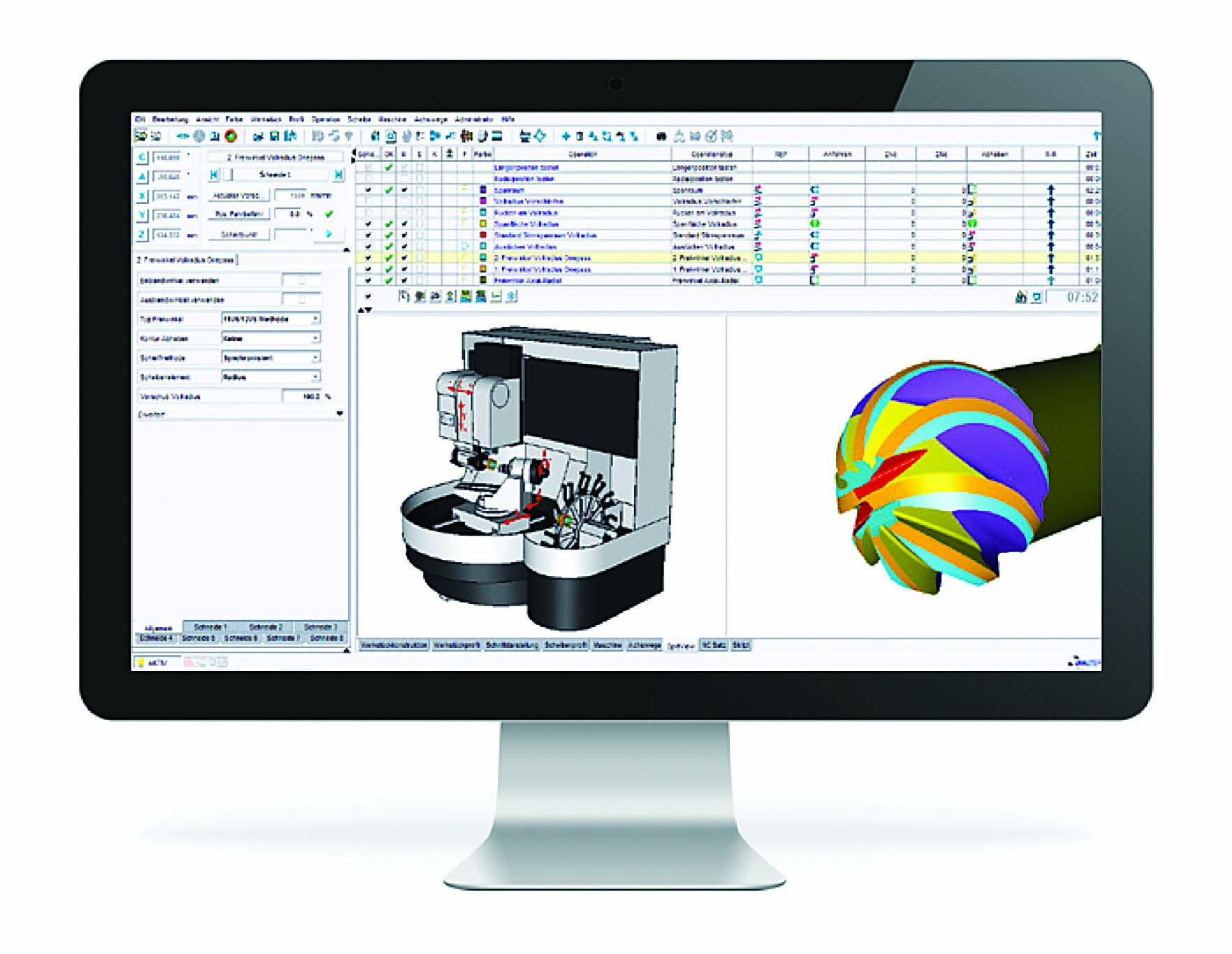

Helitronic Tool Studio is CAD/CAM software for design, programming, simulation and production. Image courtesy of Walter

The shop is a longtime user of tool grinding machines from Tübingen, Germany-based Walter Maschinenbau GmbH, a member of Bern, Switzerland-headquartered United Grinding Group, having purchased its first machine in 1999 and a second in 2006.

"Walter machines are the best fit for what we do," said Kirst, who doubles as operations engineering manager. "We're not a big regrind house. The business lies in more technical step tooling. And the software the Walter machines come equipped with, even in 1999, is far better than that offered by other manufacturers' machines. But once we learned of the new Helitronic Tool Studio software and all it could do, we knew it would provide us with the boost in efficiency, cost savings and speed we were looking for to be more competitive in today's manufacturing environment."

Helitronic Tool Studio, which is CAD/CAM software for design, programming, simulation and production, came with Dew Tool Grinding Services' new Walter Helitronic Basic five-axis machine. The extremely rigid gantry-style machine sharpens and grinds a wide spectrum of precision tools and offers complete machining in single-clamping cycles. The Walter Helitronic Basic's field of applications covers all rotationally symmetrical tools for machining metal, as well as special tools and parts with complex geometries.

The software combines ease of programming with great flexibility. Operators easily can program machining steps and movement sequences for rotationally symmetrical standard tools and specialty tools. In operation, the tool depicted on the CNC display corresponds with the tool being machined — a feature based on the tried-and-true method of "What you see is what you grind." This means that, as early as the design phase, Dew Tool Grinding Services can review a finished part via 3D simulation. If necessary, the shop can correct programming before the grinding wheel ever touches the part, saving time and money.

"The leap from Walter Window Mode, which was the software on the older machines, to Helitronic Tool Studio has just been absolutely phenomenal," Kirst said. "Turnaround time means everything for our shop, and it was the one area that had over the years grown to be a challenge for us. With our new Walter and its Helitronic Tool Studio software, we've been able to speed up delivery from three or four weeks down to only two, allowing us to better compete. Our customers always knew they were getting a good custom tool from us, and now they're getting it faster, which is improving their experience. That's where I see the difference."

Helitronic Tool Studio came with Dew Tool Grinding Services' new Walter Helitronic Basic five-axis machine. Image courtesy of Walter

Although he was apprehensive about using a new software program, it didn't take long to appreciate the improvements.

"Being able to grind the tool virtually on-screen before we even put a wheel in motion has already saved me countless dollars in wheels, as well as in raw material," Kirst said. "We also saw immediate improvements in the quality of our tools because we know exactly where the wheel is going to go and what it's going to grind before we start. If I need to make three parts for a customer, I get three perfect parts. I no longer have to make four or five to get those perfect three."

He also likes the ability to program and verify programs offline using a PC with Helitronic Tool Studio, which is particularly important because of the complex parts that the shop produces. This capability eliminates the need to stop after each operation, giving more confidence in the accuracy of the tools being made.

"We're able to program offline and transfer the program to the machine from a memory stick," Kirst said. "That saves a lot of time, and it's usually correct with very little adjustment needed. Before Helitronic Tool Studio, we had to be very cautious about how the machine was going to be set up and come in for the next grind. The accuracy with Helitronic Tool Studio was a huge improvement in productivity for us."

Other software features helping the shop be more productive are an assistant that provides common programming parameters, which can be entered for standard tool families, and a knowledge base that recommends speeds and feeds for different operations.

"These recommendations have also made a tremendous improvement because we're running a lot faster," Kirst said. "Because of the way the new software is grinding drills, for example, and applying the recommended speeds and feeds, we've taken drill pointing from 15 minutes on our other machines to maybe four to five minutes on the new one."

Additionally, the software has all but removed the need for manual operations, which improves quality and saves time and money. The shop also has been able to adjust speeds and feeds to further boost the output of its older Walter machines.

The efficiency and productivity of the new machine frees up some of Kirst's time, so he spends less of it on shop operations and more of it on building his business. Because the machine has added capacity to his operations, he is working on expanding his client base across the nation.

"Every time someone has to handle a part, it costs money," he said. "The new Walter has allowed us to be more competitive with our pricing because for some parts we're looking at 15 to 20 minutes compared to an hour and 15 minutes. So the machine and its technology (have) made an impact on our bottom line by being faster and, at the same time, allowing me to optimize my workforce."