Spiral Machining

Spiral Machining

There has been an increase in demand for scroll, or spiral, compressors as the accuracy of the methods used to make them have improved.

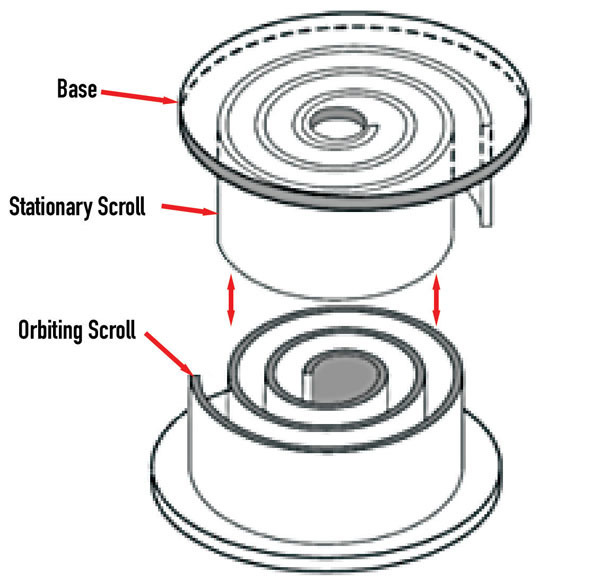

There has been an increase in demand for scroll, or spiral, compressors as the accuracy of the methods used to make them have improved. Scroll compressors are used to compress refrigerant or air to create vacuums. A scroll compressor has two Archimedes spirals nested together. Figure 1 shows components of a scroll compressor, and figure 2 shows how it works. The gas enters at two places on the outside of the scrolls and exits through a hole at the center of the fixed scroll. Patented in 1905 by Leon Creux, this is an example of an inventor being way ahead of the curve. Creux could never make a unit that worked. The way that a scroll compressor seals in the gas is the conundrum. In figure 1, the open ends of the helixes have a groove to accept O-ring material that sets against the base of the other spiral. That seals the unit axially. Radially the unit is sealed by the gap between the stationary and orbiting spirals. The smaller the gap, the better the seal and efficiency of pumping. But if they touch, it is trouble.

The efficiency is determined by pumping losses. The closer the outer surface of the inner scroll comes to the inside surface of the outer scroll, the less leakage there will be. This phenomenon is mathematically explained by exponential functions — so microns matter.

A spiral is a curve whose radius is equal to a constant multiplied by an angular displacement from zero. It is a continuous curve — not an arc or a straight line, and not a bunch of little steps like Stepper motors make. Servo motor drives are better in this application because they produce continuous motion. Using G code to interpolate a spiral tool path moving in two linear axes is an approximation. And as the size of the spiral decreases, the amount of approximation increases. Also, when milling machine axes change direction, there is a backlash error. Ball screws have backlash.

A very accurate spiral tool path can be generated using a CNC rotary table in conjunction with one axis of linear motion on a CNC milling machine. The milling cutter is positioned at the beginning of the cut. Now constant feed rate linear motion of the milling machine is interpolated with constant feed rate rotary motion of the rotary table until the end of the spiral cut. The axes of motion do not change direction, so there is no backlash error. And, since the feed rates are constant, there is no interpolation error. Now the tool path error is the pitch error of the milling machine's ball screw coupled with the radial runout of the rotary table. Switzerland- based pL LEHMANN makes rotary tables with a radial runout of 2-3 microns, or about 0.0001". Milling machines are made with a lead screw pitch error of that magnitude. Now the tool path error is 0.0002" or less. Pretty good.

Using one feed rate over the whole cut will produce ever increasing or decreasing chip load. In order to get a more even chip load and, hence, more consistent surface finish, the programmed motion can be divided into segments with increasing or decreasing feed rates for both linear and rotary motion.

This machining process is also much simpler to program than spiral interpolation.

As I have said before, an accurate tool is a good tool; an inaccurate tool is an expensive tool.