Thread milling logistically

Thread milling logistically

Switching from taps to thread mills increases efficiency.n

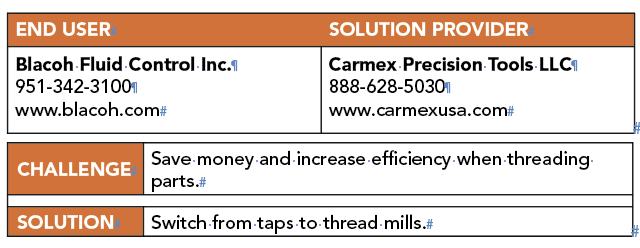

Located in Riverside, California, Blacoh Fluid Control Inc. manufactures pulsation dampeners, inlet stabilizers, back pressure valves and other products designed to move flow and reduce pulsation and shock in fluid systems. Because the products are tailored to individual needs, part runs are typically short and workpiece materials vary widely.

"We thread materials from 10/32" to 2.5" (7.94 mm to 63.5 mm) in diameter," said Engineering Manager David McComb. "Materials range from metals, including stainless, Hastelloy, alloy 20 (a high-nickel-content material) and others, to PVC, CPVC, PTFE and the very expensive PVDF plastics."

A key product line for the company is calibration columns, which have an end cap that is 177.8 mm (7") in diameter and require 12 threads per inch.

"The column houses a transparent tube and accompanying label imprinted with precise gradations to monitor the correct amount of fluoride, sodium hypochlorite or other chemical used in water or wastewater treatment," McComb said.

In selecting a tool supplier, he sought a manufacturer with a wide selection of off-the-shelf threading tools in a variety of sizes and configurations, which brought him to Hartford, Wisconsin-based Carmex Precision Tools LLC."I reasoned that a logistical approach involving the optimum selection of off-the-shelf threading tools encompassing all the sizes we need would result in the greatest economic benefit in terms of tool cost, as well as simplifying the supply chain and avoiding the high cost of special tooling," McComb said. "It has also aided us in identifying the best tools for the job.""Thread milling and turning have always been Carmex's greatest area of specialization," said Leonard Ahumada, applications engineer at Carmex Precision Tools. "And as a result, we offer an extensive choice of tools extending from our Tiny Tool and Swiss tool lines, which are solid-carbide tools for working in small diameters, as well as larger indexable thread mills and specialty inserts for turning that are designed according to part print specifications. We worked with David to assist him in developing a matrix of 24 standardized tools in the machining center that accomplish all his machining needs, as well as the Blacoh thread milling requirements. An optimum selection of material-specific threading inserts and toolholders was also defined for use in the turning centers, where part runs are typically larger."Examples of parts that Blacoh Fluid Control threads with thread mills from Carmex Precision Tools. Some parts require multiple thread configurations while both inner- and outer-diameter threading are necessary for key hard-to-machine parts. Image courtesy of Blacoh Fluid Control

"By partnering with Carmex," McComb said, "we've been able to achieve significant economies using standard tooling. We formerly used taps in our threading applications but ultimately found them to be expensive and less effective than thread milling. Tap breakage results in scrap parts, and a dull tap will score the material. This was a real problem for us as some of our materials, such as Hastelloy, have a hardness of 45 Rockwell.

"The tools we currently use are extremely precise, and we have been able to attain better diameter control and eliminate problems with shallow hole threading. Because we use indexable inserts, we can replace the inserts without needing to touch off the tools again.

"Our single-supplier relationship also delivers greater efficiencies, and Leonard and his team continually monitor our usage and needs."

"David's approach has been exceptionally valuable to Blacoh by taking a wide view that includes not only the tooling but the supply chain," Ahumada said. "He has been able to optimize the threading process while deriving significant economic benefits."