The toughest material on Earth

The toughest material on Earth

Researchers probe metal that measures the highest toughness ever recorded.

Scientists have measured the highest toughness ever recorded of any material while investigating a metallic alloy made of chromium, cobalt and nickel. The metal is extremely ductile, which in materials science means highly malleable, and impressively strong, meaning that the metal resists permanent deformation. The strength and ductility of the metal also improve as it becomes colder. This runs counter to most other materials in existence.

The team was led by researchers from Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory.

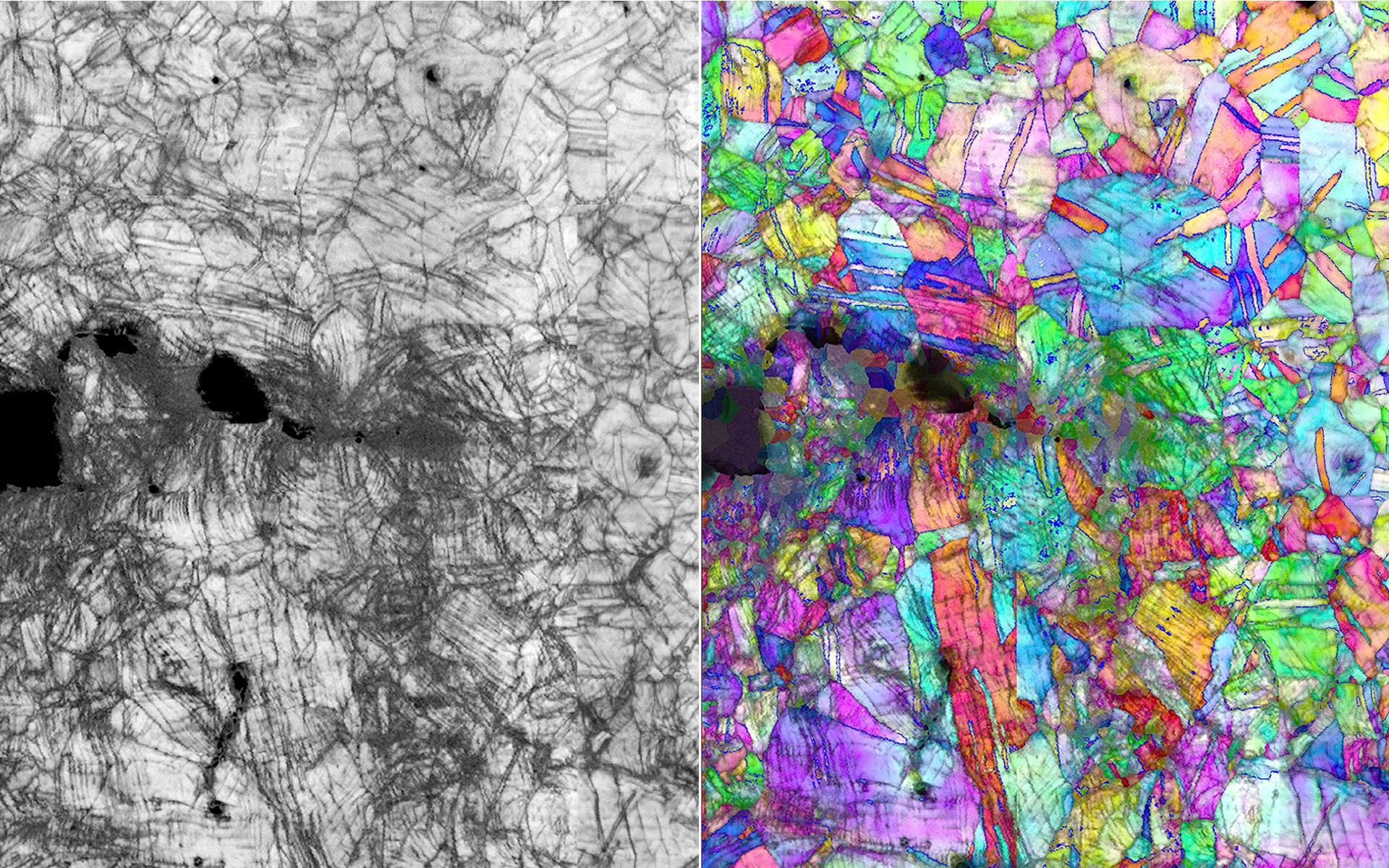

Microscopy-generated images show the path of a fracture and accompanying crystal structure deformation in the CrCoNi alloy at nanometer scale during stress testing at 20 K (-424 F). The fracture is propagating from left to right. Image courtesy of R. Ritchie/Lawrence Berkeley National Laboratory

"When you design structural materials, you want them to be strong but also ductile and resistant to fracture," said project co-lead Easo George, the governor's chair for advanced alloy theory and development at ORNL and University of Tennessee. "Typically, it's a compromise between these properties. But this material is both, and instead of becoming brittle at low temperatures, it gets tougher."

"The toughness of this material near liquid helium temperatures (20 kelvin, -424 Fahrenheit) is as high as 500 megapascals square root meters," said research co-leader Robert Ritchie, senior faculty scientist at Berkeley Lab's materials sciences division and Chua professor of engineering at University of California, Berkeley. "In the same units, the toughness of a piece of silicon is one, the aluminum airframe in passenger airplanes is about 35, and the toughness of some of the best steels is around 100. So 500, it's a staggering number."

Now that the inner workings of the CrCoNi alloy are better understood, it and other high-entropy alloys are one step closer to adoption for special applications. Although these materials are expensive to create, George foresees uses in situations in which environmental extremes could destroy standard metallic alloys, such as in the frigid temperatures of deep space. He and his team at ORNL also are investigating how alloys made of more abundant, less expensive elements — there is a global shortage of cobalt and nickel due to their demand in the battery industry — could be coaxed into having similar properties.

The progress is exciting, but Ritchie warns that real-world use could be a ways off for good reason.

"When you are flying on an airplane, would you like to know that what saves you from falling 40,000 feet is an airframe alloy that was only developed a few months ago?" he said. "Or would you want the materials to be mature and well understood? That's why structural materials can take many years, even decades, to get into real use."

— Aliyah Kovner