Trending toward productivity

Trending toward productivity

The U.S. economy appears to be on the mend. In January, the Manufacturers Alliance for Productivity and Innovation gave a tentative thumbs up to sustained business expansion through the first half of 2013. And the Institute for Supply Management's manufacturing index rose again in January, painting an optimistic picture. Maybe it's time to buy that machining center you've been thinking about.r Before you whip out your checkbook, though, some homework is in order. There's a lot more to machining centers than spindle speeds and rapid traverse rates. Sure, you've had good results over the years buying machines based on that, but that might be the wrong criteria in this brave new manufacturing world. You're facing growing competition from overseas and down the street, so you owe it to yourself to take a look at what's changed in the years since you bought your tried and true 20"×40" vertical machining center.

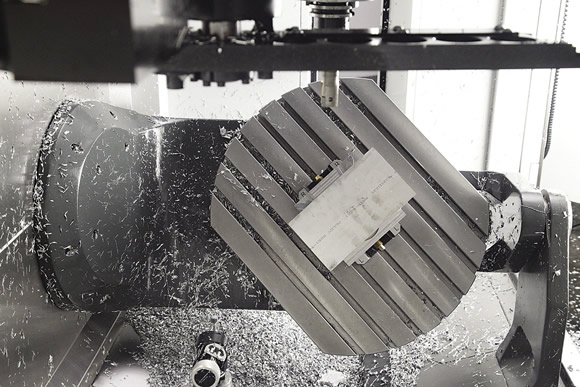

Courtesy of Haas Automation

Five-sided machining in a single setup on a Haas UMC-750 vertical machining center.

The U.S. economy appears to be on the mend. In January, the Manufacturers Alliance for Productivity and Innovation gave a tentative thumbs up to sustained business expansion through the first half of 2013. And the Institute for Supply Management's manufacturing index rose again in January, painting an optimistic picture. Maybe it's time to buy that machining center you've been thinking about.

Before you whip out your checkbook, though, some homework is in order. There's a lot more to machining centers than spindle speeds and rapid traverse rates. Sure, you've had good results over the years buying machines based on that, but that might be the wrong criteria in this brave new manufacturing world. You're facing growing competition from overseas and down the street, so you owe it to yourself to take a look at what's changed in the years since you bought your tried and true 20 "×40 " vertical machining center.

3+2>5

Most everyone's seen them at trade shows—5-axis wonder machines whittling away at intricate shapes such as motorcycle helmets, jet turbine blades and titanium knee implants. Recently, 5-axis machining centers have redefined many shops' definition of complexity. But maybe you don't do complex aerospace work, or you simply can't afford to spend $500,000 on a machine tool. And 5-axis programming is way too complicated, right?

Think again. "In our market at least, 90 to 95 percent of these machines are used for '3+2' rather than simultaneous 5-axis work," said Bryan O'Fallon, product technical specialist at Haas Automation Inc., Oxnard, Calif. "Sure, you still have the guys doing impellers and turbine work, but that's more the exception than the rule. The typical 5-axis user is the shop looking for setup reduction."

Why use the most challenging machine in the milling department for setup reduction? Because a 5-axis machine doing 3+2 machining can produce a complete workpiece in a single clamping (3+2 machining is where 3-axis milling is executed with the part locked in a tilted position using the 5-axis machine's two rotational axes).

"Let's say you have a cube-shaped part," O'Fallon said. "A lot of shops might tumble a part across multiple vises on a VMC to hit each side of the workpiece or maybe use two machines. But with 3+2 you can rotate the part to every face and get it all done in one clamping, assuming it's been properly fixtured."

This one-and-done method requires far less handling than similar setups on a 3-axis machine, reduces fixturing costs and provides higher workpiece geometric accuracy, he added. "Once you've rotated the part into position, it's just like programming a 3-axis VMC," O'Fallon said. "It's much simpler than simultaneous 5-axis machining."

And the 3+2 process is appropriate for more than this kind of one-off work. Production shops with relatively simple parts also can take advantage of it, according to O'Fallon. "You might have a pallet with multiple sides, maybe a tombstone fixture, and use it like a horizontal machine. For large volume work, you can load lots of parts in a single setup."

To support these shops, Haas developed the UMC-750 VMC, a $150,000 machine that is an alternative to more costly 5-axis machining centers. "You can still do 5-axis simultaneous machining on the UMC-750, but to address the considerations just mentioned, we've really pushed 3+2 for this machine," O'Fallon said.

Why should shops consider a 5-axis machine when they've been getting inexpensive 3+2 capability for years by bolting 2-axis trunnion-rotary tables to 3-axis VMCs? The problem with this option, he said, is the Z-axis travel."There's a lot smaller work envelope with a trunnion-rotary table. When a trunnion rotary is mounted to the table of a VMC, it eats up a considerable amount of the Z-axis travel, even before fixturing the part. The UMC-750 provides a much larger work envelope—a full 20 " of Z-axis travel—with better access to the part, for about the same price as a trunnion-equipped VMC. It's attractive for job shops in particular that might be doing low-volume 5-axis work one day and 3-axis production the next."

Hiring R2-D2

Did your operator call in sick again, the day after the Super Bowl? Looks like the only way you'll get those parts done on time is to run them yourself.

For many small shops, the challenge isn't the machine, it's the people. Sure, if you had sufficient production volumes, you could buy a robot and tell that operator to stay home forever, but everyone knows robotic parts handling is only for automotive suppliers, right?

Not so, said Darryl Smith, automation manager for Doosan Infracore Machine Tools, Pine Brook, N.J. Over the past 18 months, Smith has seen increased interest in automating machining centers.

"For production work, you just can't afford to have somebody stand in front of a VMC anymore," Smith said. "The cost of automation is dropping, it's increasingly difficult to find qualified people and you're not going to be successful against foreign competition without it. Companies have to do more with less."

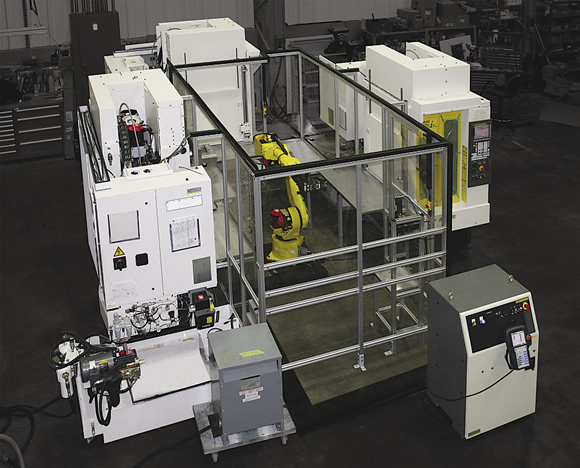

Courtesy of Doosan Infracore Machine Tools

Automation can work for short-run production, even in lot sizes once considered too small for robotics.

Good reasons, perhaps, but robots are still considered expensive and difficult to set up. Smith countered that the cost of robotics for machining centers has dropped more than 25 percent over the past 5 years. "When you look at automation, everything works toward lower cost—cheaper computers, better software and higher robotics usage throughout the industry."

As an example, Smith cited Doosan's Doocell automation system, with a 6-axis FANUC M-10iA articulating robot for part loading/unloading. The complete $130,000 system includes the robot, automatic doors and grippers.

Changeover is simple and quick. "To change grippers, there are no more than 12 screws to take out," Smith said. "I was at a shop that was doing complete changeovers in less than 30 minutes."

The reason automation works for low-volume production is simple. "If I have 10 jobs that I know repeat on a regular basis, I'm going to get really spanking good at turning those jobs over," he said. "Over the course of a year, I'll get faster and better at it. The trend is toward using some level of automation for this type of repeat work, which keeps shops in business."

Smith admitted that the use of robots in job shops is still relatively rare. "This is far from mainstream," he said. "But it's a painful fact for everyone that there are fewer people going into manufacturing, and it doesn't appear to be getting any better. Look at Bobcat in North Dakota, or John Deere in Iowa. Labor costs are relatively low in these areas, but these companies have tons of automation. So it's not just about the people; part quality, process predictability—everything factors into it."

Real Estate Considerations

Doing more with less extends to conserving shop floor space as well. "We're seeing smaller footprints in the equipment itself," said Michael Minton, national application engineering manager for Methods Machine Tools Inc., Sudbury, Mass. "Especially in medical and other high-tech industries, floor space is at a premium where parts are small and volumes are high. Job shops as well are looking for smaller footprints without losing the work area in their machines. People want to fit as many spindles as possible into a given floor space."

To address this issue, Methods offers the FANUC RoboDrill D21-series VMC, the smallest of which is sometimes referred to as the "phone booth" at just 40 " wide. The machines also offer reduced processing time and lower costs, according to Minton. As a rule, a 30-taper spindle ramps up faster and is tooled more economically than a 40-taper spindle—search any popular tooling catalog and you'll see 30-taper toolholders costing 20 to 30 percent less than their larger cousins.

"In situations where you don't have automation, small machines make it much easier for an operator to feed multiple machines since he doesn't have to walk as far." Minton also pointed out that small machines fit well in an automated cell configuration, optimizing floor space and allowing the robot to efficiently service the machines.

Courtesy of Doosan Infracore Machine Tools

Remove a handful of screws, pop in a new gripper, and this robot is ready for the next job.

Courtesy of Methods Machine Tools

High productivity in a small space: a FANUC robot serves three RoboDrill "phone booth" machining centers.

Pallet changers that take up less floor space are also available. For example, Methods offers the Feeler VMP-580APC, a 40-taper machining center with an integrated rotary-style pallet changer. The entire package fits into a 10-sq.-ft. space.

Minton noted the machine changes pallets in 6 seconds and requires less maintenance due to fewer moving parts than traditional shuttle-type changers. "Where most verticals shuttle in from the side, the pallets on the VMP are picked up by the door," he said. This makes for fast pallet changes with a simple mechanism.

Another builder with an eye toward conserving floor space is GF Agie- Charmilles LLC, Lincolnshire, Ill. Product Manager Ken Baeszler said a good choice for high-production milling is a machine with the smallest possible footprint and integrated automation.

Baeszler described machinists as strategy managers. "They're looking at tool towers of up to 220 positions, with upwards of 12 pallets in the changer," he said. "They have to set up the machines to do quick changeovers and maximize uptime. This means certain types of tools are always on the machine, and certain types of pallets are readily available, so they can be quick and flexible. These people have to be able to run production day in and day out and get the same results."

One technology that supports this goal is intelligent tool measurement, with high-speed optical measurement replacing laser measurement. "Where we once used lasers to measure tools, some of our machines now have high-speed optical measurement," Baeszler said. He explained optical measurement is generally more accurate than lasers, with repeatability ranges in the area of ±0.00004 " and capability to measure tools as small as 0.008 " in diameter. And where lasers get confused by debris on the tool, optical measurement can digitally "clean" the cutter while it's still spinning, giving the operator the ability to check for chipped and worn tools without having to stop the machine. "There's a lot of research going on in this area," Baeszler said.

Another area where R&D is taking place at AgieCharmilles is "smart" thermal control technology. "We spend a lot of time on intelligent thermal control, as well as spindle-growth detection systems," he said. "There's a great deal of software-driven technology available right now. When you talk about intelligent thermal compensation, for example, it doesn't take much for a machine to warm up and start moving things around, especially in the 5-axis world, where any geometry errors tend to stack up. So thermal control is a very important field of research.

"Thermal growth is a lot like a debt crisis," Baeszler continued. "You can't just solve it with one thing. We have water-cooled spindles and rotor shafts, so we can provide cooling where it needs to be, and intelligent control systems to make adjustments where necessary. With the right machine options, we can restrict spindle and axial growth to less than 10µm. Our job is just to eliminate as much risk as possible."

There's an App for That

Paul Webster, engineering manager for FANUC FA America, Hoffman Estates, Ill., agreed that smart machine control is a key trend. New control options remotely monitor machine tools through a Web-style interface, he said. This opens the door to centralized control of the entire shop floor via wireless connection to an iPad, for example.

Sometimes it's not all about how smart your control is, but what you can plug into it. Open architecture allows machine tools to interface with third-party software, external devices such as tool presetters and even your shop's MRP system, offering possibilities for integration only imagined 10 years ago.

Okuma America Corp., Charlotte, N.C., has had an open architecture platform for more than 7 years, according to Brian Sides, product technical specialist. "Anything you can plug into your desktop PC you can plug into our THINC control," he said. Want to read measurements from a micrometer into a statistical process control program resident on your machine control? No problem, but it doesn't stop there.

"Since we have an open application programming interface, we can interface to that same SPC software and make decisions based on data there," Sides said. "If the software sees that tool wear is headed toward a yellow bar, the control can offset the tool accordingly or swap it out for a replacement tool. Now you don't have an operator putting in a minus instead of a plus or missing a decimal point. It's all about saving time and guaranteeing the right data gets entered."

Another benefit of collecting machine data is that it can be shared with the toolcrib for better management of tooling inventory. "It was actually one of our customers who came up with the concept," Sides said. "He said, 'The control has a PC, the presetter has a PC and the crib has a PC. Why don't you just get those machines to talk to one another?' "

The result is a control that, based on information from a bar code on a job traveler, sends a request to a vending machine, which also has a computer. That computer sends tool length, diameter and wear information back to the control, which then opens the proper drawers for the machinist to collect the tools and decrements tool inventory accordingly.

"All the operator has to do is load the tools in the correct magazine location and he's up and running," Sides said. "That same job traveler can tell the control to download machine setup sheets, toolpaths, part drawings and videos."

Courtesy of FANUC

Users can remotely monitor machine tools with a Web-capable FANUC control and compatible tablet device.

This kind of traceability is important for machine shops that have to comply, for example, with regulations from the U.S. Food and Drug Administration for medical parts, which can include audits of drawings, program versions, process sheets and other process control information.

"By doing all that electronically, you avoid situations where the operator runs the wrong version of the program or inspects the parts to an old version of the drawing," Sides said. "It also lets you track production in real time, so you don't have to depend on the operator clocking in to an enterprise resource planning system to see what's happening on the floor."

It's this last point that Sides calls "the final frontier" in machine controls. "We see connecting to ERP software as the next step. We're still exploring how that can be done."

However it turns out, there are still plenty of tools that allow shops to cut costs and improve quality. Whether it's reduced setup through 3+2 machining, space-thrifty machine designs or CNCs smarter than R2-D2, part manufacturers shouldn't accept the status quo when they are investing in new machining centers. CTE

About the Author: Kip Hanson is a contributing editor for CTE. Contact him at (520) 548-7328 or [email protected].

Contributors

Doosan Infracore Machine Tools

(973) 618-2500

www.doosaninfracore.com/machinetools

FANUC FA America

(888) 326-8287

www.fanucfa.com

GF AgieCharmilles LLC

(888) 326-8287

www.gfac.com/us

Haas Automation Inc.

(800) 331-6746

www.haascnc.com

Methods Machine Tools Inc.

(877) 668-4262

www.methodsmachine.com

Okuma America Corp.

(704) 588-7000

www.okuma.com