When to adopt a new technology

When to adopt a new technology

Determining the appropriate time to implement new technology.

Technological advances in machining can take many forms. Some come from the technological shifts in our daily lives, like smartphones and tablets, while others are industry-specific, such as advances in CAD/CAM software and high-speed machining.

The desire to improve drives manufacturers to seek new ideas and devices and make changes to technology when appropriate. However, keep in mind that change has no inherent value. Adopting a new technology can be beneficial or detrimental. Always question the desire to adopt technology and change the status quo by asking: Why are we doing this? Do we have a valid reason to change? Are we prepared?

Of course, some changes are easily justified. Customer requirements often force the adoption of new ideas and technologies. In 1991, while I was running the family machine shop, our largest customer handed down an edict that all vendors adopt electronic data interchange (EDI) to receive purchase orders. This change was significant because our shop didn't have any computers at the time and, therefore, had to make a large investment in hardware and software. We were concerned about the cost as well as our ability to operate the system. However, the change to EDI proved very beneficial, allowing us to grow the amount of business we received from that customer.

In addition, 4 years after adopting EDI, our machine shop won a job much larger than anything we had previously undertaken. As a result, we purchased our first CNC machining center—a huge technological shift from manual machines. The machine worked so well that we purchased three more CNC machines that year and saw our business grow exponentially.

A Mori Seiki NC lathe, shown at Ellison Technologies in Charlotte, N.C., has a large control cabinet with an obsolete tape reader on the left. This machine was technologically advanced when it was built in 1975.

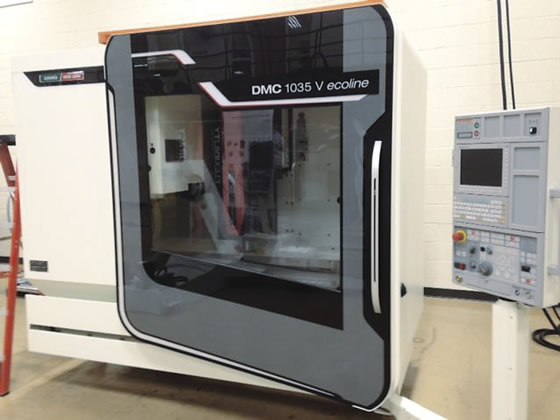

This new DMG MORI vertical machining center at Ellison Technologies is capable of making the highly dynamic moves associated with high-speed machining.

It's no secret that acquiring and retaining skilled personnel is difficult in today's market. Technology that allows workers to be more efficient is also easily justified. Automation that enables one person to operate multiple machines or eliminates a mundane task can free hands to perform more valuable work or allow a highly skilled employee to efficiently transfer knowledge to someone with fewer skills.

Sometimes it is necessary to adopt change to retain good employees. For small shops, it may mean adopting some of the perks provided by larger organizations, like direct deposit, shop Wi-Fi and computers in the break room for personal use.

But don't let marketing glitz or the prospect of being left behind force a bad decision. New technology is not always appropriate. For example, a previous employer purchased four large coordinate measuring machines, loaded with options, which cost several hundred thousand dollars each. The company justified the purchase by saying it needed them to ensure it could provide a high-quality product to the global market.

However, the capability of the CMMs was far more advanced than the manufacturing process and made it easy to collect unnecessary data. We created a monster that quickly bottlenecked the entire shop, forcing engineers to sift through reams of data to determine if we had good parts, bad parts or just erroneous data. We eventually resorted to template gages, micrometers, scales and calipers to measure the parts instead.

Also, avoid letting the "wow factor" of new technology or a novel use of existing technology lure you into "solving" a nonexistent problem. Make sure there is a clearly defined problem before implementing a strategy to solve it.

For instance, after a company I worked for visited a facility where iPads were used to electronically deliver manufacturing work instructions, a manager announced that we should adopt the practice to improve quality. Each of our processes had a set of work instructions to be followed while the work was performed. Quality issues plagued the plant, and each issue that was found generated a set of corrective actions. The corrective actions always included a revision to the work instruction.

However, most of the work instructions were so poorly written that the machinists and welders never followed them. Although an electronic system would have delivered those poor instructions more efficiently, it left the root cause of the problem unaddressed.

It's critical to determine if your infrastructure and human capital can support a technological shift. Advances in CAM software and cutting tools permit programmers to generate dynamic toolpaths for HSM. Machine tool design evolves to keep pace with the advances in software and cutting tools, but many older machine tools are incapable of performing under the same parameters because they cannot process commands and move at the same speeds as newer ones. Therefore, a shop full of older machines probably won't benefit from software that creates dynamic toolpaths.

Most importantly, the people that will use the new technology—machinists and operators—must support a technology shift. They are the key to successful implementation. Failure to recognize their importance will jeopardize the implementation of any project.

Timing is critical. It may be necessary to introduce new technology in phases, giving each phase time to succeed and allowing participants to become acclimated to new ways of doing things. Failed attempts only serve to harden some people to any change, making each successive attempt more difficult.

New technology has always played an important role in manufacturing and always will. In the quest to improve, manufacturers will continue to adopt new ideas and devices. Successful implementation of new technology relies on a clearly defined strategy, capable infrastructure and the willingness to change. CTE

About the Author: Christopher Tate is senior advanced manufacturing engineering for Milwaukee Electric Tool Corp., Brookfield, Wis. He is based at the company's manufacturing plant in Jackson, Miss. He has 19 years of experience in the metalworking industry and holds a Master of Science and Bachelor of Science from Mississippi State University. E-mail: [email protected].