Working hard to avoid workhardening

Working hard to avoid workhardening

Thread milling nickel-base superalloys requires minimizing workhardening.

When a component must resist corrosion while withstanding a high level of heat, such as one found in the combustion chamber of a jet engine, part designers often decide to make the part from a nickel-base superalloy. Whether Inconel 600, Haynes 230, Hastelloy B or another metal from that group, they all are challenging to thread or otherwise machine.

That is because those alloys have a high level of ductility, so they tend to easily workharden when cut, according to Marlon Blandon, product manager for thread milling at Emuge Corp., West Boylston, Massachusetts. As a result, prior to threading, drilling can workharden the surface of a hole to be threaded. A continuous threading application like tapping, in turn, can generate such a high level of heat that it workhardens the bore to the point that it can't be threaded.

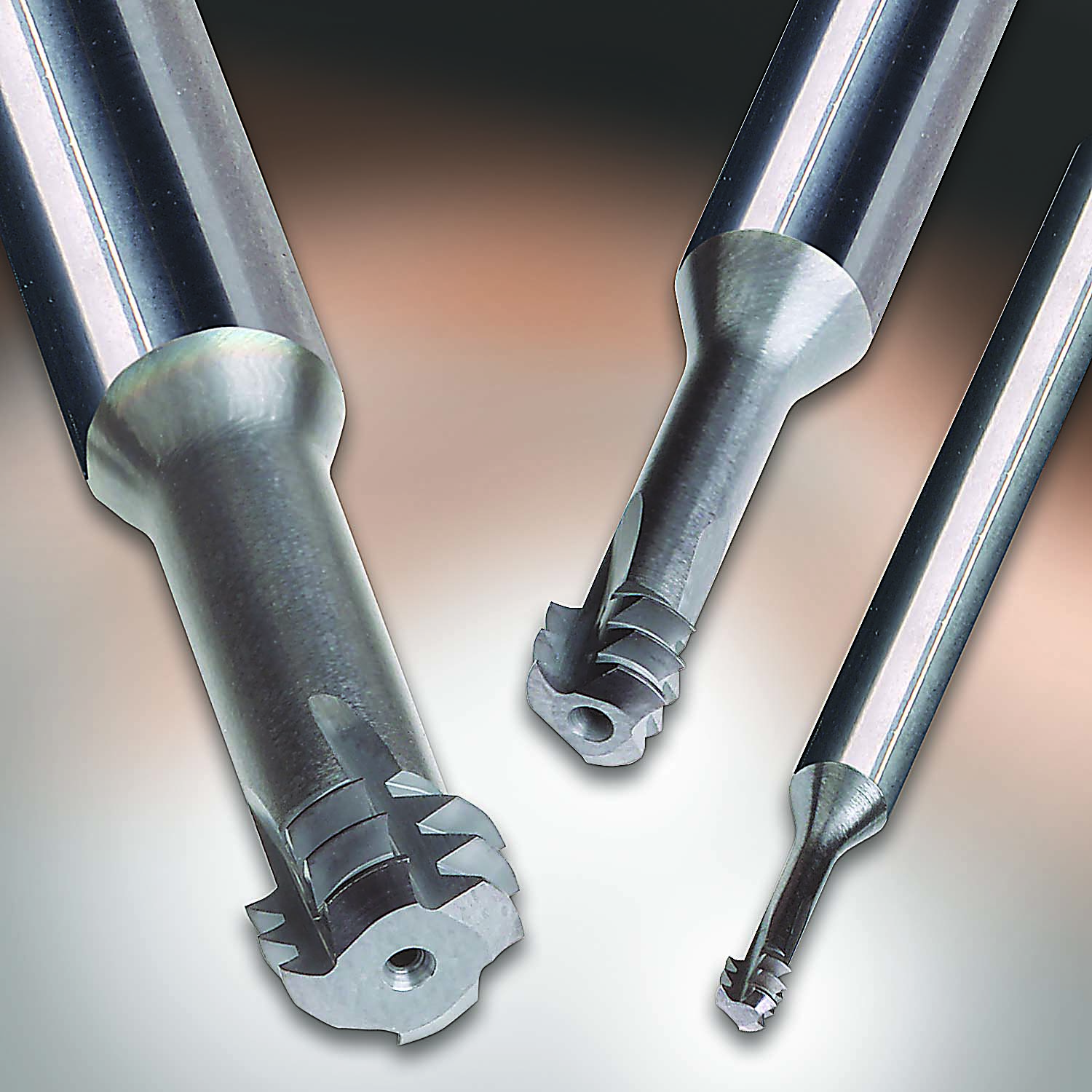

Emuge reports that its Threads-all ZGF S-Cut thread mills offer aggressive cycle time reductions and impart a fine finish when threading nickel-base alloys. Image courtesy of Emuge

Blandon suggests thread milling with the appropriate tool instead. The thread mill should be made of solid carbide and have a positive rake angle and sharp cutting edges. "We use a proprietary micrograin carbide that allows us to grind very sharp edges," he said. "The finer the carbide grade, the easier it is to create a sharp edge."

Those cutting edges should then be coated to protect them against heat. A TiCN coating can be deposited to resist heat without adding too much expense to a tool. However, a multilayer TiAlN coating is even more effective because once the coating is heated, it hardens more to enhance the protection, Blandon noted.

Hold On

Once an end user has the correct thread mill, a suitable toolholder is needed. According to Blandon, avoid ER collets at all costs because they are designed for linear cutting, either in and out or side to side but not for 3-axis circular interpolation, which thread milling requires.

In addition, shrink-fit toolholders might not be adequate because they often don't have enough thickness to surround the tool shank and enable vibration-free thread milling, he added. Vibration produces chatter marks on threads, which require re-cutting. "You don't want to make too many passes," Blandon said, "because every time you make a pass, you are generating heat and the material is workhardening."

A better choice is a holder with a side-locking screw that pushes the entire wall of the shank into the holder and improves rigidity, he said.

Blandon added that Emuge offers the FPC toolholding system. "It's a gear-driven system that pulls the entire shank of the tool into a clamping sleeve. Then this clamping sleeve gets tightened with a specific torque into the holder itself. That is more than enough for thread milling."

The next element for successfully threading nickel-base superalloys is to have the right program. To minimize heat, Blandon recommends reducing the cutting speed and taking a "big bite" of the workpiece so the cutting edge goes below any potentially workhardened zone. "We penetrate and grab as much as we can so the heat goes with the chip and doesn't stay in the part."

Circular Circuit

In addition, programming the thread mill to start cutting with a 180° entry curve instead of the typical 45° or 90° entry curve enables a "soft entry," Blandon said. "This makes it so the point of the tool has a little bit more room to start from a small chip and work its way into a bigger chip."

Creating more room is also important when applying external coolant. To enable coolant to effectively access where it is needed, users should select a single-plane thread mill that only engages a part with one line of teeth at once rather than a cutter with a full milling section, Blandon said. "It creates a lot of free cutting. You don't have pressure on an entire milling section."

Although the single-plane design reduces the amount of heat in the cut, he said it also extends the cycle time, which isn't the highest consideration when thread milling an expensive, mission-critical part. "However, for substantially higher productivity there is a three-tooth solution with a left-hand helix flute—our unique ZGF S-Cut tool design—that simultaneously roughs and finish-cuts threads in one pass. It dramatically reduces cycle times while extending tool life."

To help ensure successful thread milling, Blandon said Emuge usually provides complimentary programming instructions, including recommended speeds and feeds, with the thread mills it sells.

As industries place increased demands on heat-resistant part requirements, the need for tools to effectively thread and otherwise machine those parts follows.

"We have seen tremendous expansion in the aerospace industry, at least when it comes to jet engines," Blandon said. "There is a high demand for tools for those heat-resistant materials."

For more information about Emuge's Threads-all ZGF S-Cut thread mills, view a video presentation at www.ctemag.com by scanning the QR code on your smartphone or entering this URL on your web browser: cteplus.delivr.com/2uac2