.jpg)

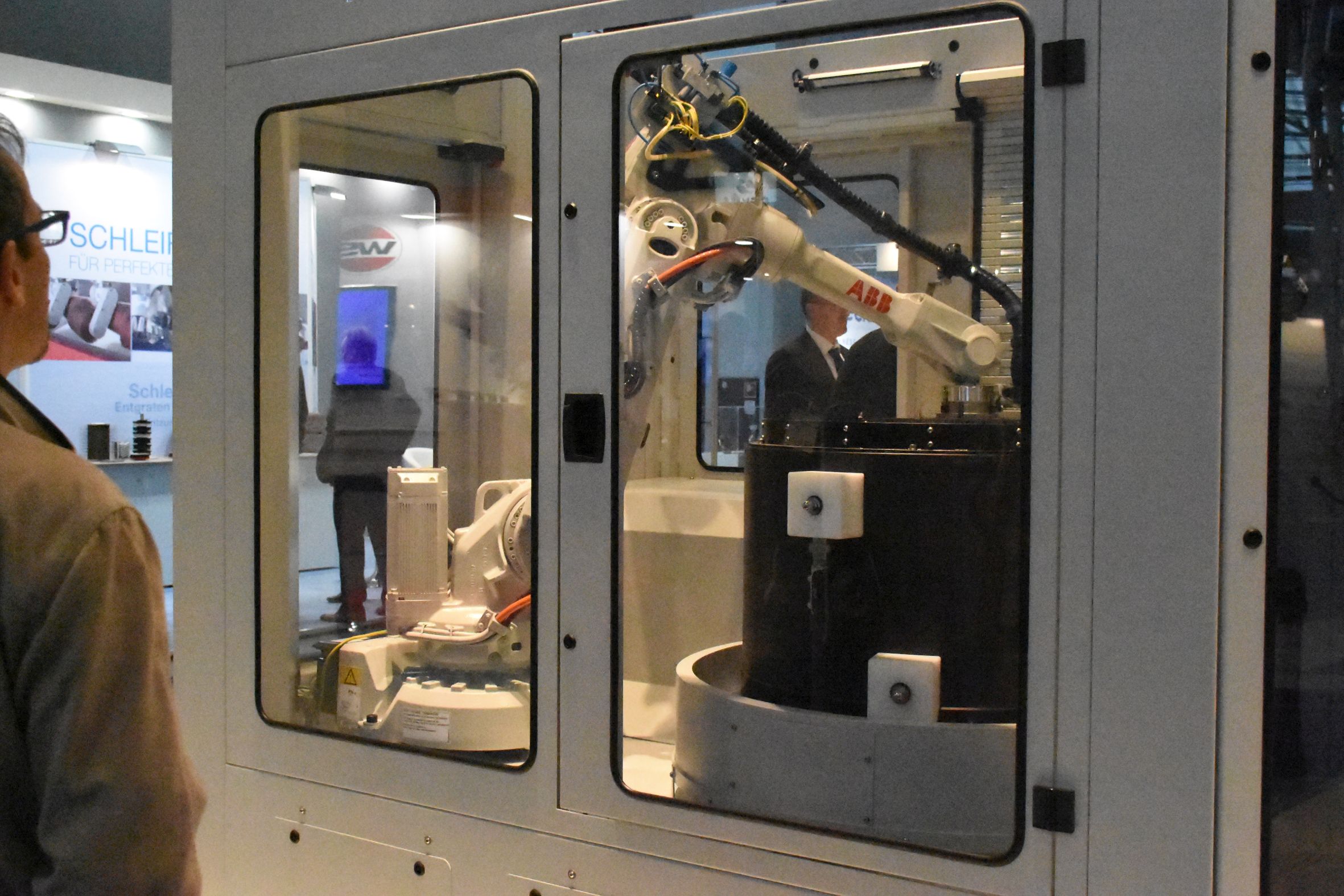

Solutions for new and changed cleaning tasks at parts2clean 2020

Hanover, Germany. The extraordinary, unpredictable situation caused by the coronavirus presents unprecedented challenges to companies worldwide. Industrial cleaning technology does not seem to play a role at first. But the solutions presented at the 18th parts2clean (27-29 October 2020) will support companies in the production and remanufacturing sectors to improve their future viability and thus emerge from the crisis stronger.